Method for constructing fully prefabricated floor slab partially-overlapped joint and component of joint

A floor and main structure technology, applied to building components, floors, buildings, etc., can solve the problems of heavy steel binding workload, reliable joints, short service life, unsatisfactory effect and construction efficiency, etc., to overcome the problems of joints Poor reliability, valuable market application prospect, scientific method and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

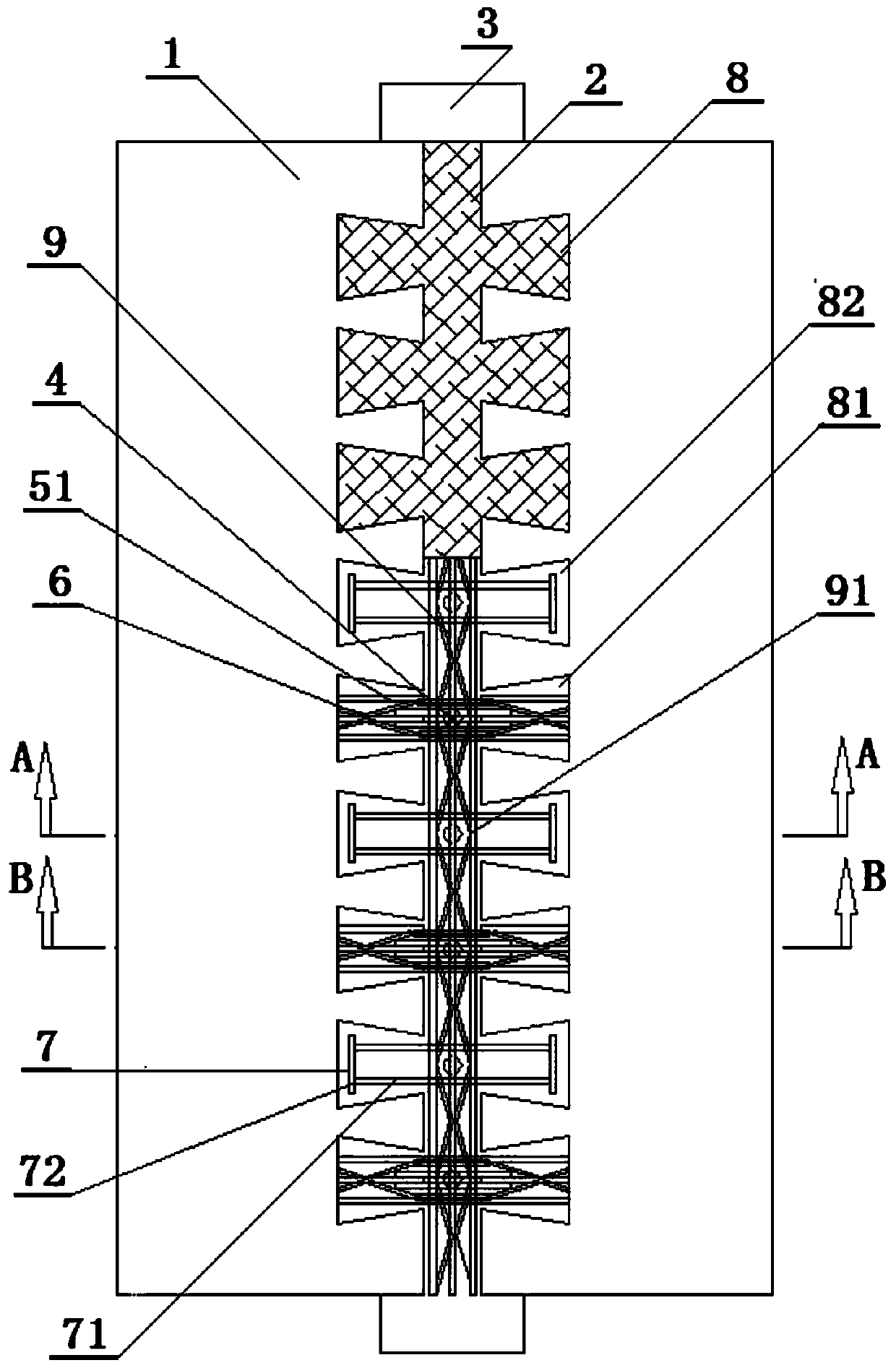

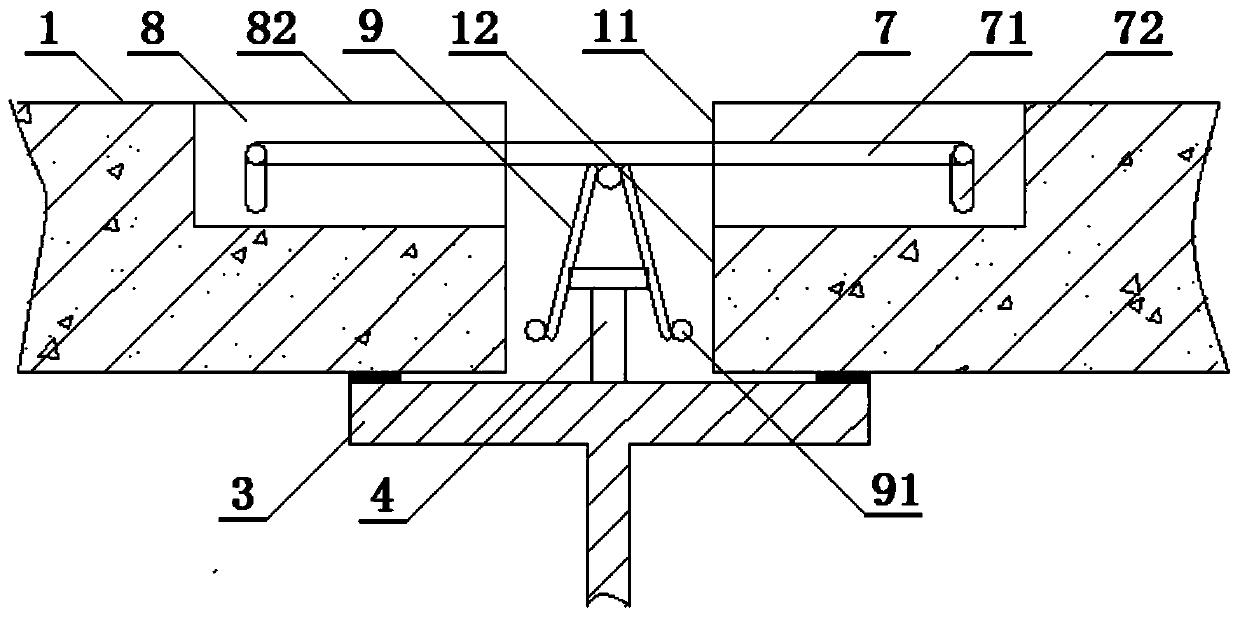

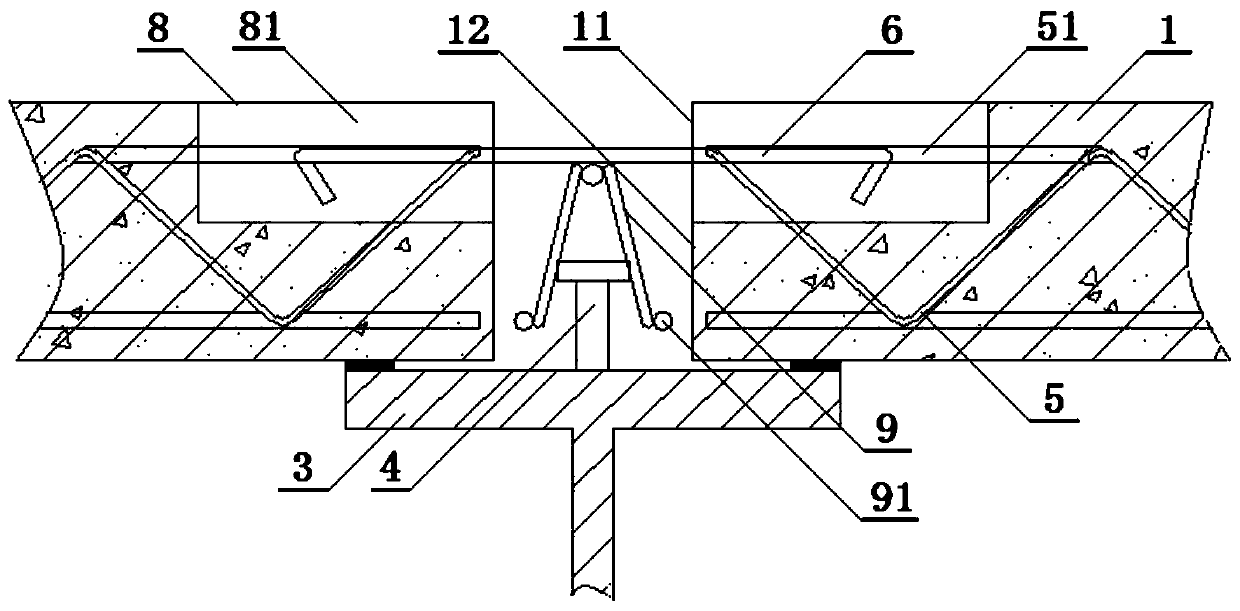

[0026] exist figure 1 , figure 2 with image 3 Among them, the fully prefabricated floor slab partially superimposed joint joint member of the present invention mainly includes a fully prefabricated floor slab 1, a post-cast concrete slab belt 2 and a main structural steel beam 3, and is characterized in that it also includes shear studs 4 and prefabricated truss reinforcement in the slab 5, the overhanging end 51 of 5, on-site additional reinforcement 6, structural shear reinforcement frame 7, several dovetail grooves 8 and on-site additional truss reinforcement 9, the post-pouring concrete slab belt 2 is composed of post-pouring double-sided dovetail joints 21 Act as, among them:

[0027] The edge of the full prefabricated floor 1 includes an upper edge 11 and a lower edge 12;

[0028] The main body of the dovetail groove 8 is wide inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com