Two-section vacuum power and water pressure power airtightness testing device

A test device and power gas technology, applied in the direction of gas/liquid distribution and storage, pipeline system, mechanical equipment, etc., to achieve the effect of low manufacturing cost, simple structure, and overcoming unsuitable maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0042] Example

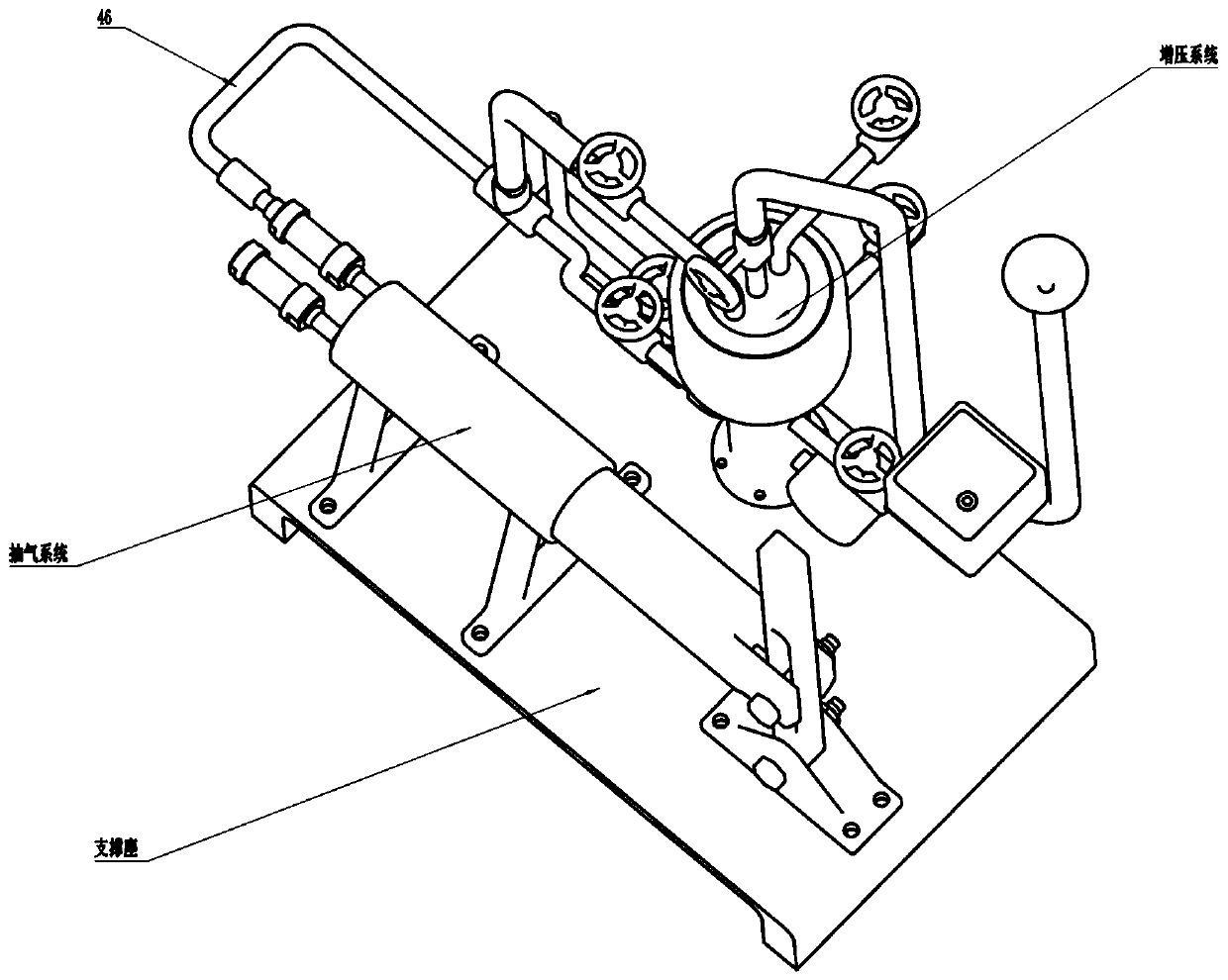

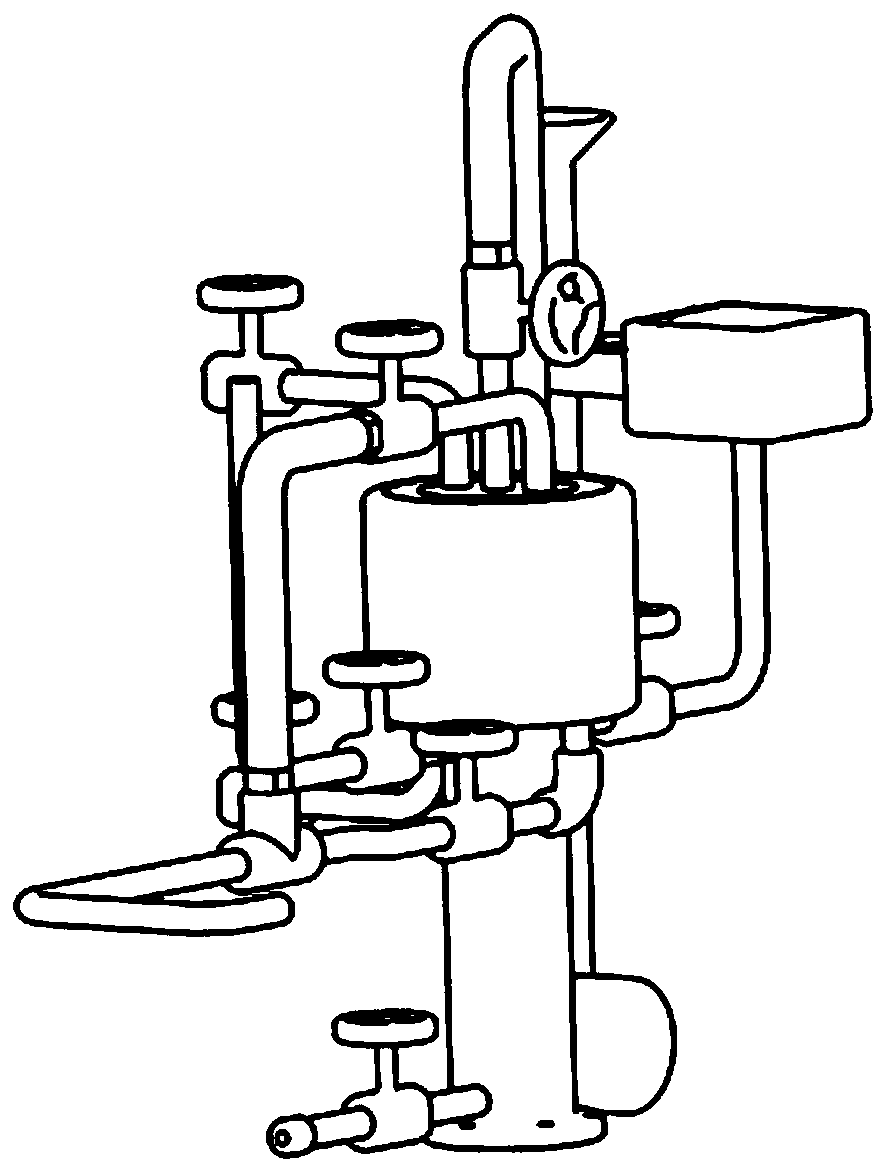

[0043] This embodiment provides two vacuum power and hydraulic power air tightness testing devices, such as figure 1 As shown, it is mainly divided into supercharging system ( figure 1 ) And pumping system ( Picture 10 ), the pressurization system and the air extraction system are connected and installed on the support seat; the pressurization system is divided into a vacuum power system and a water pressure system. The vacuum power system and the water pressure system are composed of their common components and their individual components, and complete the work separately , Its core component is the vacuum chamber subsystem.

[0044] Vacuum chamber subsystem (such as Figure 4 , Figure 5 (Shown) is composed of O-shaped rubber sealing ring 1, force transmitting member A2, O-shaped rubber sealing ring 3, O-shaped rubber sealing ring 4, force transmitting member B5, O-shaped rubber sealing ring 6 and supporting member 7. The O-shaped rubber sealing ring 1 and the O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com