Clamp and method for high-temperature tensile detection of small-specification metal tubular product

A technology of metal pipes and small specifications, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, and analyzing materials, etc., can solve the problems of few references and different test methods, and achieve reasonable structural design and test The effect of data stability and filling the detection gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

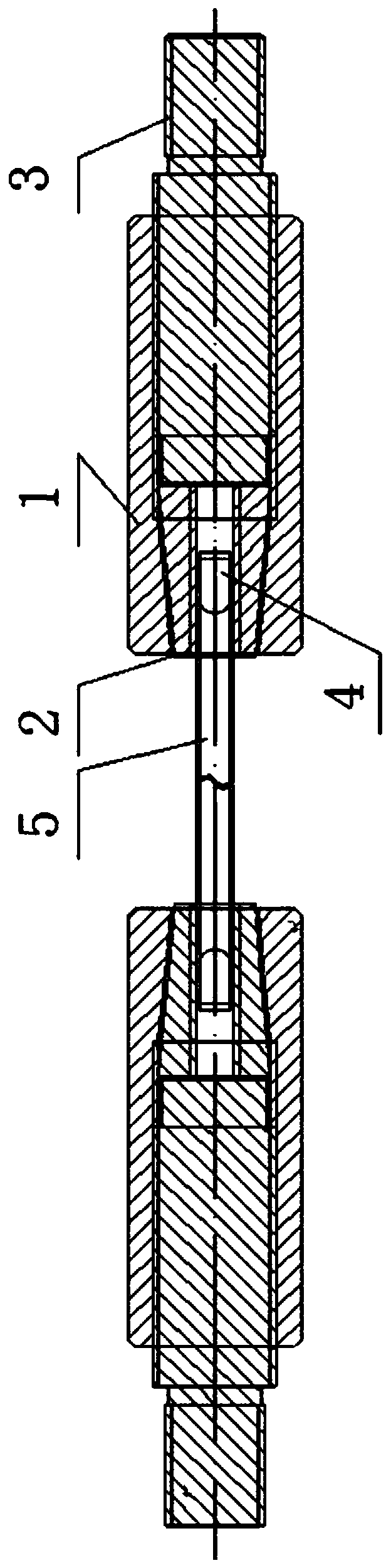

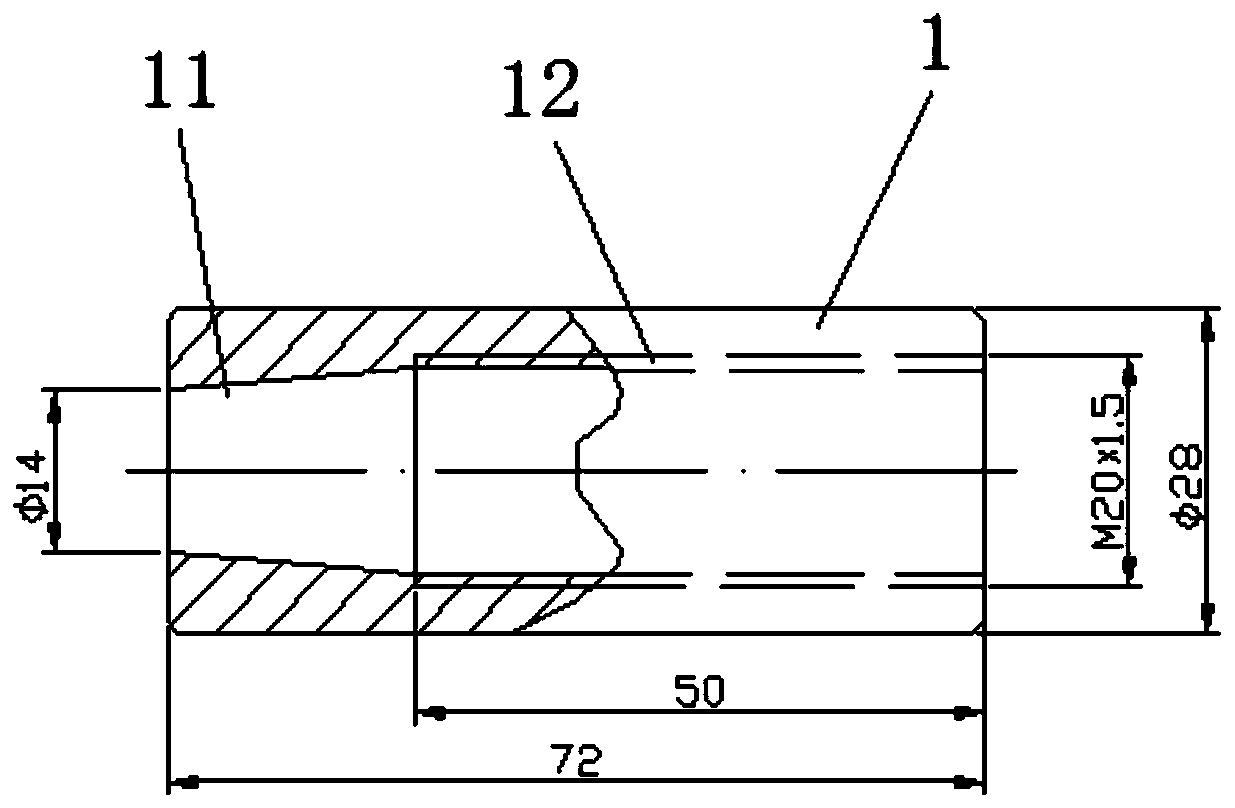

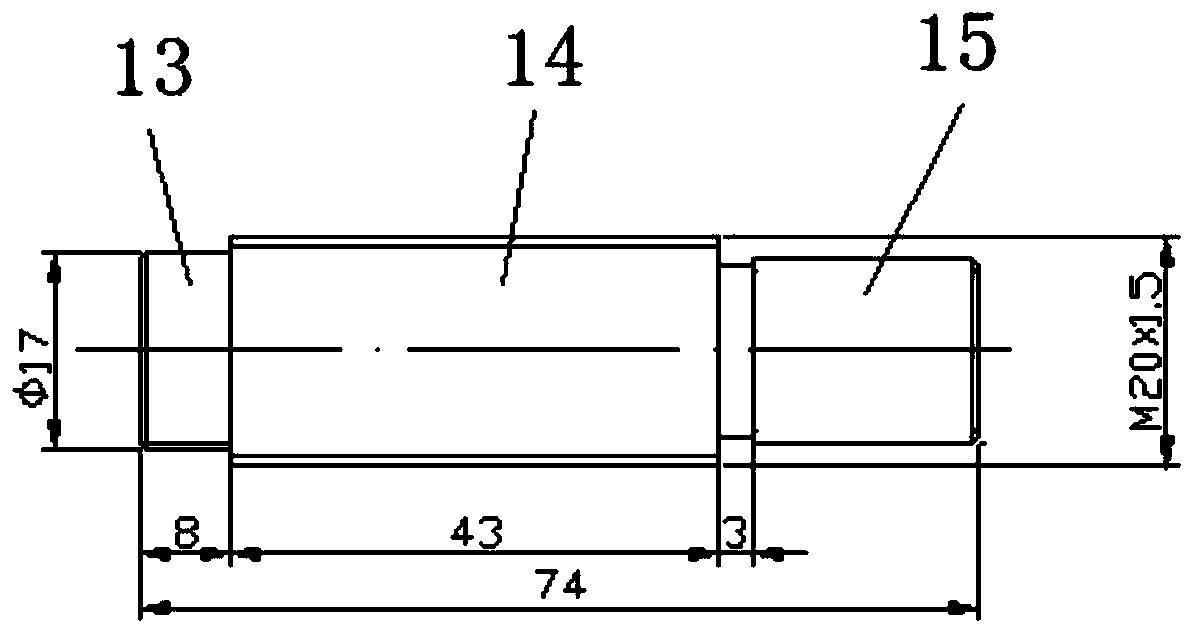

[0029] Such as Figure 1-7 As shown, a fixture suitable for high-temperature tensile testing of small-sized metal pipes includes a sleeve 1, a clamping cone 2, a top 3, a plug 4, and a connecting rod 6. One end of the sleeve 1 has a tapered mouth 11 and the other One end is an internal thread 12; the clamping cone 2 is in the shape of a truncated cone, and the inside thereof is provided with a threaded hole 16, and the clamping cone 2 is composed of two equal parts; the top cone 3 is provided with an external thread; the stopper 4 One end is bullet-shaped, and the plug 4 is used to insert the two ends of the metal pipe test piece 5 and support the pipe wall, and the two ends of the metal pipe test piece 5 are put into the threaded holes 16 of the clamping cone 2 respectively. Inside, the clamping cone 2 is put into the tapered mouth 11 in the casing 1, and the top cone 3 is screwed into the casing 1 to compress the clamping cone 2 to clamp the metal pipe test piece 5 , the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com