Compressor with flooded start control

A technology for compressors and control modules, which is applied to compressors, liquid fuel engines, refrigerators, etc., and can solve problems such as compressor bearing wear, compressor failure, and damage to internal moving parts of the compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Example embodiments will now be described more fully with reference to the accompanying drawings.

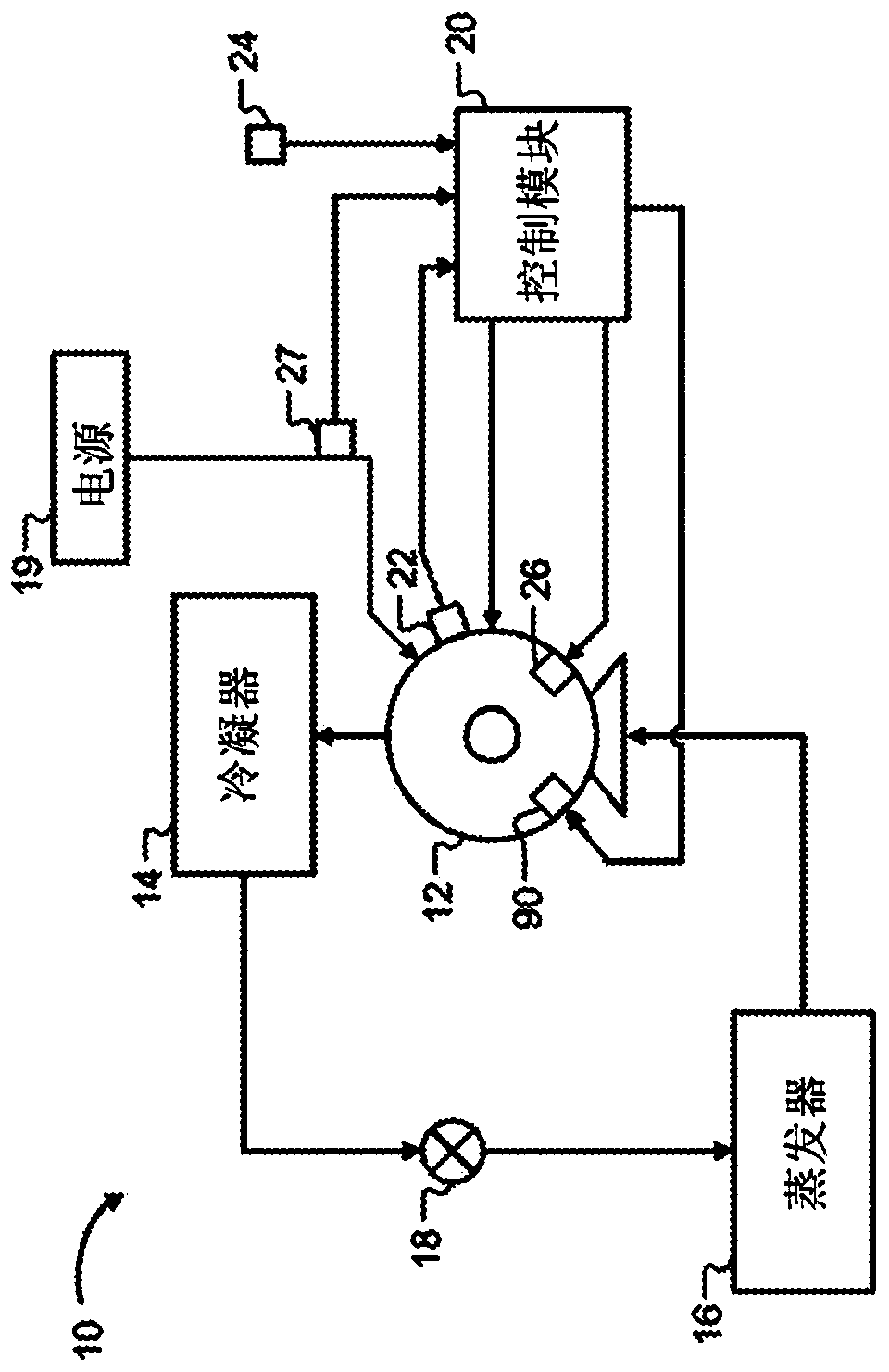

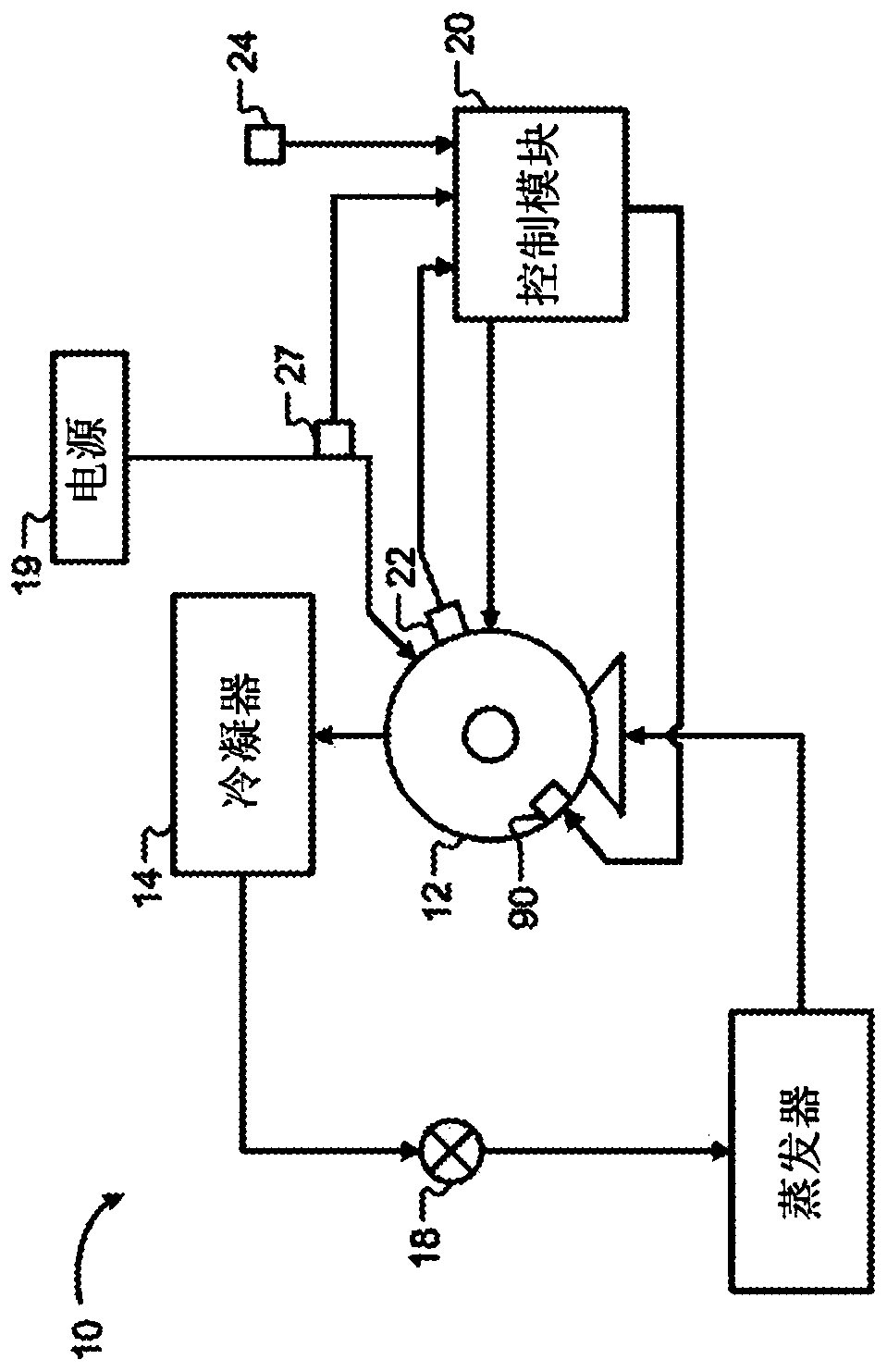

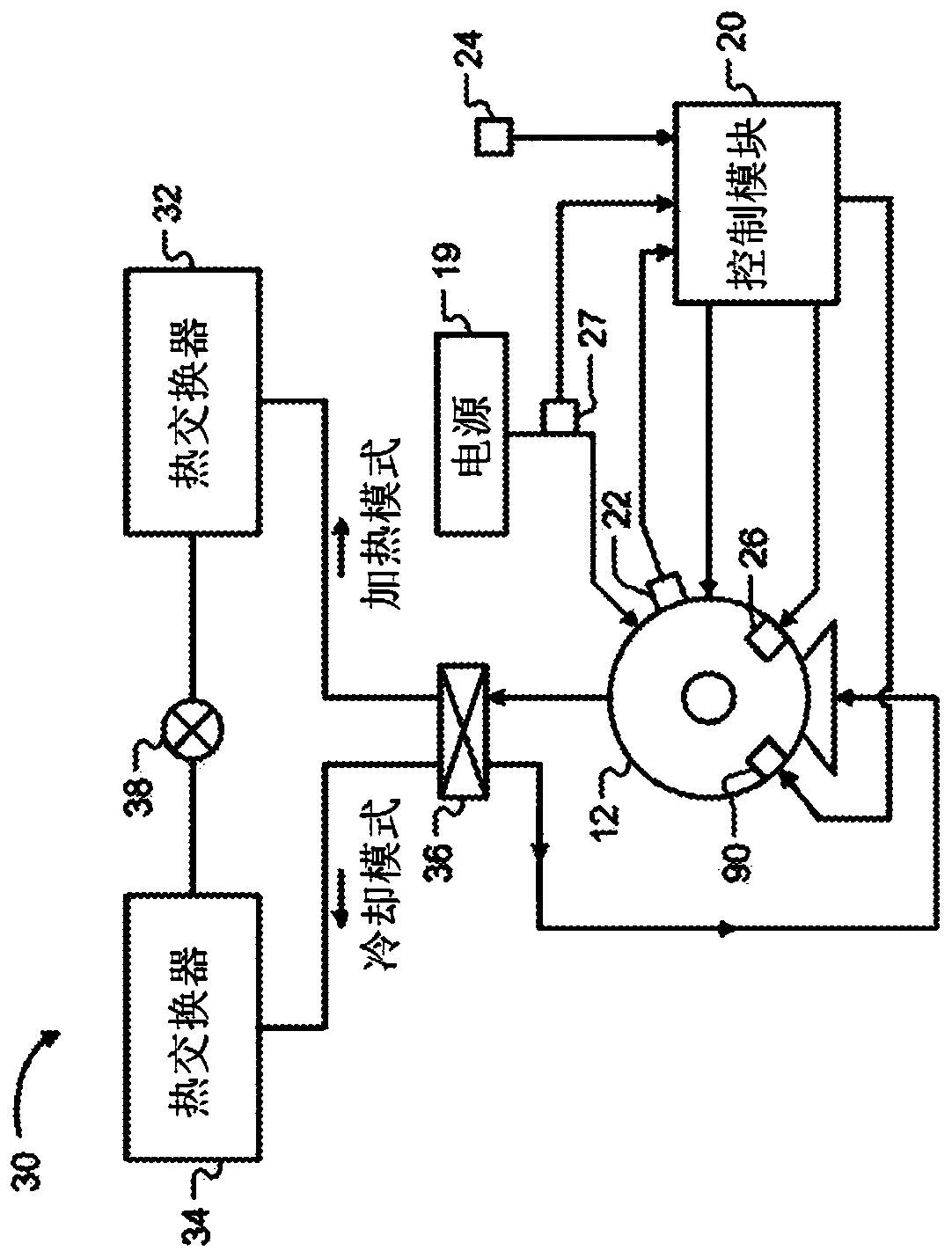

[0053] refer to Figure 1A , shows a refrigeration system 10 and includes a compressor 12 , a condenser 14 , an evaporator 16 and a flow control device 18 . Refrigeration system 10 may be, for example, an HVAC system in which evaporator 16 is located indoors and compressor 12 and condenser 14 are located outdoors in a condensing unit. The flow control device 18 may be a capillary tube, a thermal expansion valve (TXV), or an electronic expansion valve (EXV). The compressor 12 is connected to a power source 19 .

[0054] The control module 20 controls the compressor 12 by turning the compressor 12 on and off. More specifically, the control module 20 controls the compressor contactor 40 ( image 3 shown in ), the compressor contactor 40 connects the electric motor 42 of the compressor 12 ( image 3 shown in ) is connected or disconnected from the power supply 19.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com