Apple cleaning and sorting system and process

A sorting system, Apple's technology, applied in sorting, application, food processing and other directions, can solve the problems of wasting human resources and high costs, and achieve the effects of saving labor costs, accurate and reliable determination methods, and accurate judgment results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

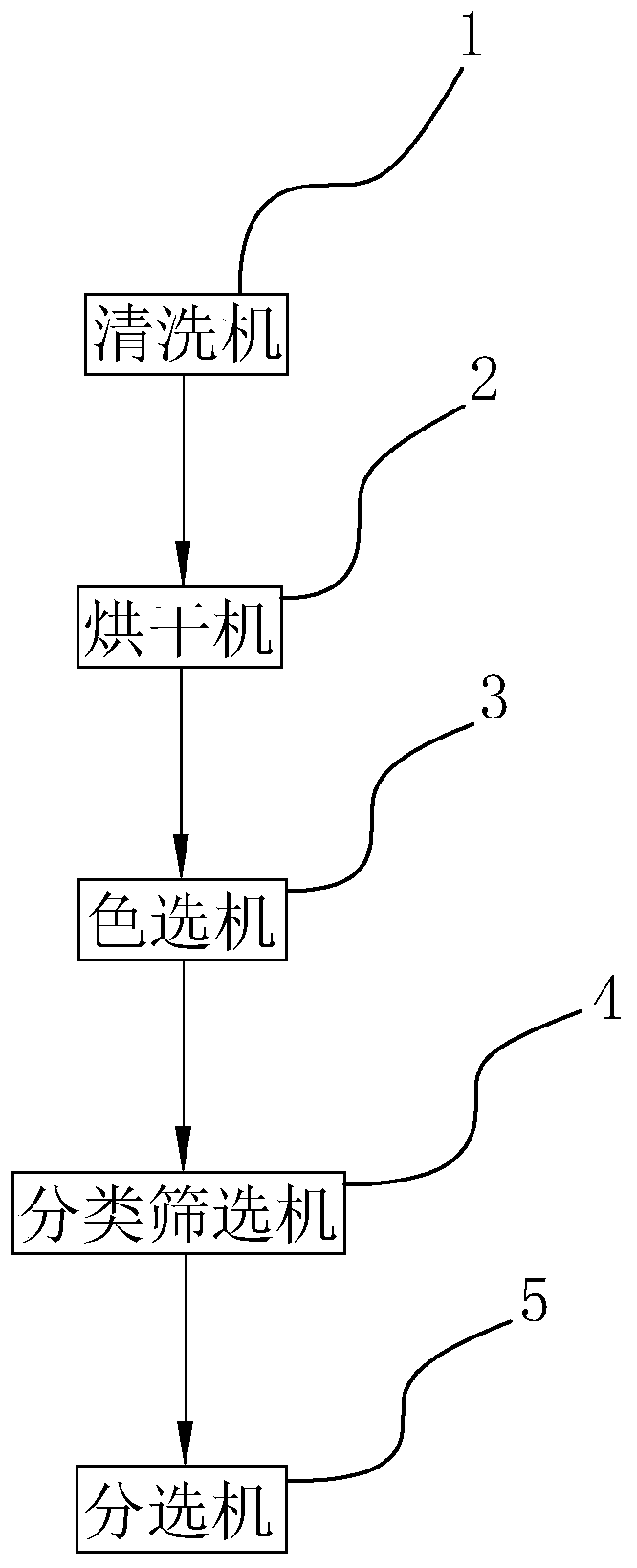

[0061] Embodiment one: a kind of apple cleaning and sorting system, such as figure 1 As shown, it includes a washing machine 1, a drying machine 2, a color sorter 3, a sorting and screening machine 4 and a two-group sorting machine 5 arranged in sequence. After the apples are put into the washing machine 1 by the staff, after three steps of washing, drying and color sorting, the apples with dry surface and no bad fruit are transported to the sorting and screening machine 4, and the sorting and screening machine 4 classifies the apples. Then they are transported to the 5 places of the two-group sorting machine for sorting, and the cleaning and sorting of apples is completed.

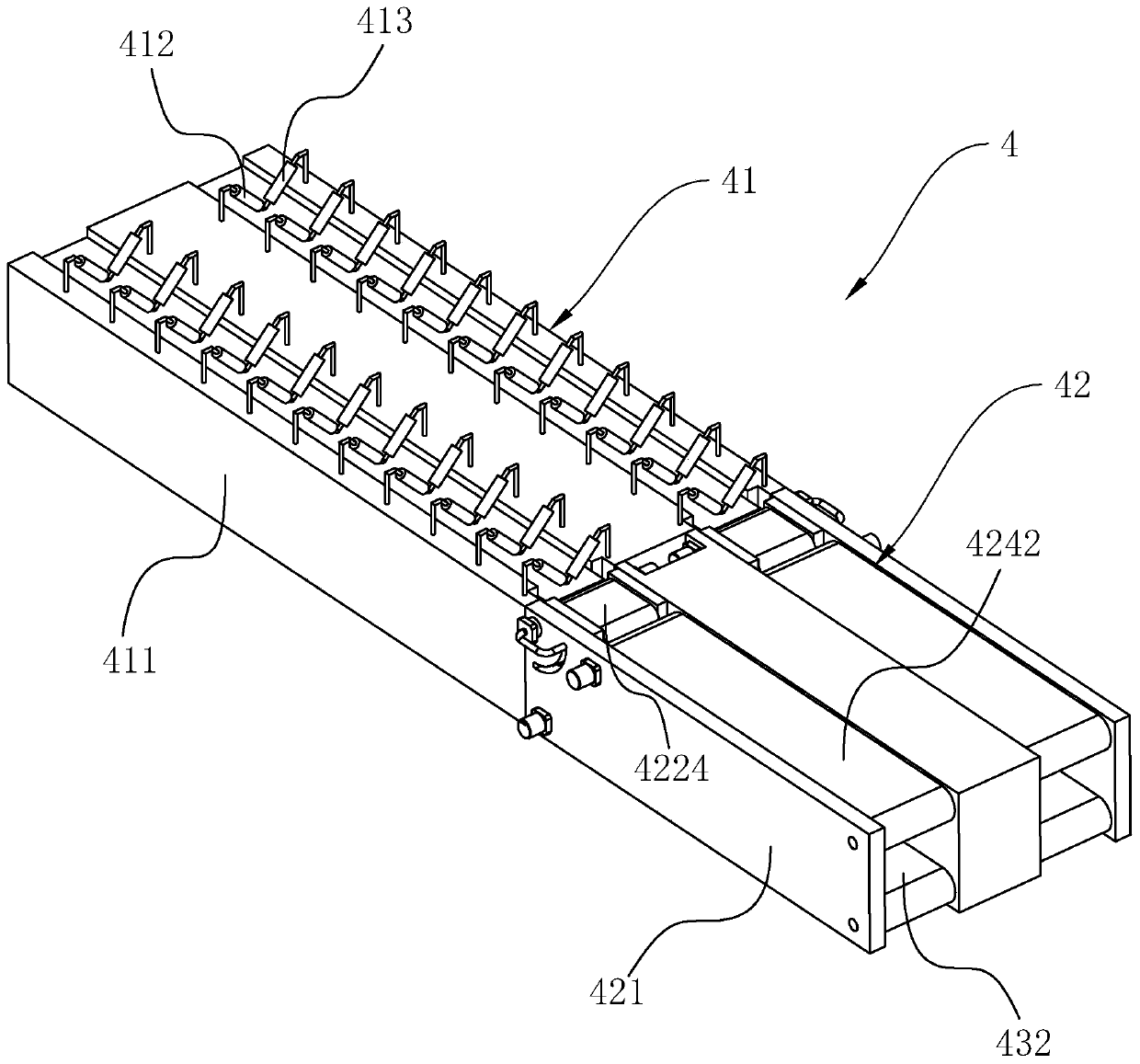

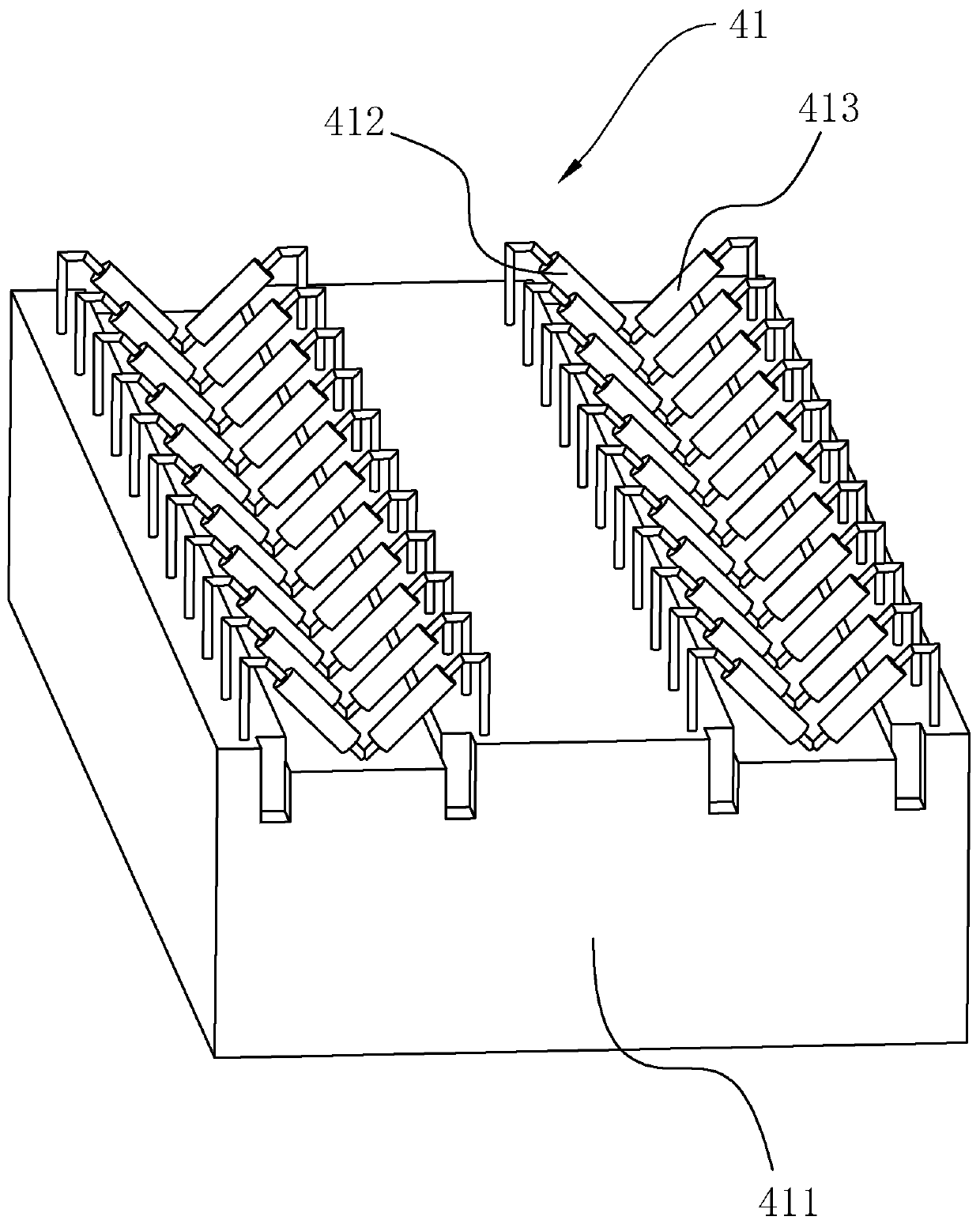

[0062] Such as figure 2 and image 3 As shown, the sorting and screening machine 4 includes a feed conveyor belt 41 connected to the discharge end of the color sorter 3 , and the feed conveyor belt 41 includes a base 411 connected to the discharge port of the color sorter 3 . The base 411 is rotatably...

Embodiment 2

[0072] Embodiment two: a kind of apple cleaning and sorting process, concrete steps are as follows:

[0073] The first step is to pour the apples into the cleaning machine 1 for cleaning.

[0074] In the second step, the cleaned apples enter the dryer 2 for drying.

[0075] In the third step, the dried apples enter the color sorter 3 to remove bad fruits.

[0076]The 4th step, apple enters sorting and screening machine 4 through feeding conveyer belt 41. The sorting and screening machine 4 allows the striped apples to fall onto the lower belt 432 to separate the striped apples from the non-striped apples. The apples with striped pattern are transported to one group of sorters 5 places along the lower belt 432, and the apples with non-striped pattern are transported to another group of sorters 5 places along the second belt 4242.

[0077] The fifth step, sorting machine 5 apples of different specifications are sorted and unloaded.

[0078] Apples with different patterns can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com