Stage flight case

A flight box and stage technology, applied in the field of stage flight boxes, can solve problems such as glue overflow and unsightly appearance, and achieve the effects of avoiding misalignment, firm connection, and accurate connection position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

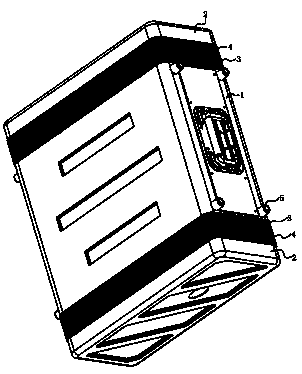

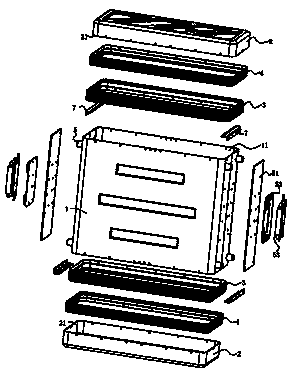

[0036] Such as Figure 1 to Figure 5 As shown, the stage flight box includes a box body 1, a box cover 2, a box side frame body 3, a cover side frame body 4 and a handle device.

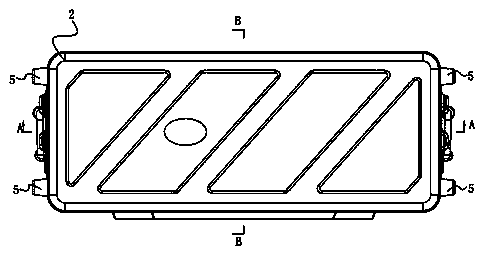

[0037] Support feet 5 are provided on two opposite sides of the box body 1 , and the support feet 5 are used to support the box body 1 . The box body 1 has an opening edge 11, in this embodiment, withfigure 1 with figure 2 For the viewing angle direction, there are opening edges 11 at the upper and lower ends of the box body 1 respectively.

[0038] The lid 2 has an opening edge 21 .

[0039] Such as figure 2 , Image 6 , Figure 7 with Figure 8 As shown, the cross-section of the box-side frame body 3 includes a box-side connecting portion 31 and a first docking portion 32. The first docking portion 32 is connected to one end of the box-side connecting portion 31 and extends inward at the middle of the box-side connecting portion 31. The first flange 33, a slot 34 is formed between the firs...

Embodiment 2

[0049] Such as Figure 14 As shown, the difference between the present embodiment and embodiment 1 is that the pulley pull bar 9 is added, and other structures are all the same. The pulley pull rod 9 includes a pull rod seat 91 , a telescopic pull rod 92 , a pull rod fixing seat 93 and a roller 94 . Pull rod seat 91 is fixed on the casing, telescopic pull rod 92 is a double pull rod structure, and one end of telescopic pull rod 92 is fixed on the pull rod seat 91, and telescopic pull rod 92 is also fixed on the pull rod holder 93, like this, telescopic pull rod 92 and casing The connection is reliable, the tie rod holder 93 is fixed on the casing, and the two ends of the tie rod holder 91 are respectively equipped with rollers 94. In this way, there is no need to install rubber wheels on the box body, and the requirements for the molding of the box body are reduced. At the same time, it is convenient to carry the stage flight box by using the pull rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com