Sloping roof precast beam lifting device used for assembly type concrete structure and installation method

A technology of concrete structure and hoisting device, which is applied in the direction of safety device, transportation and packaging, load hanging components, etc., which can solve safety problems and achieve the effect of ensuring construction quality, easy operation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

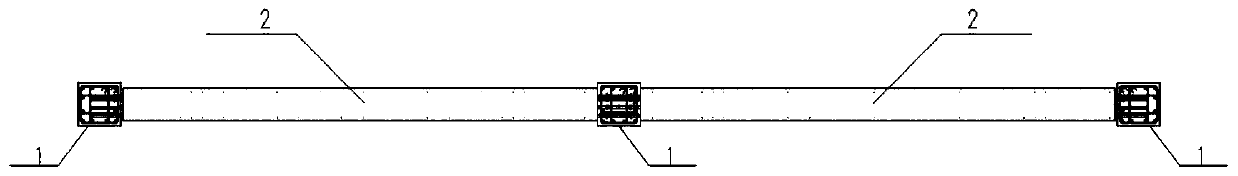

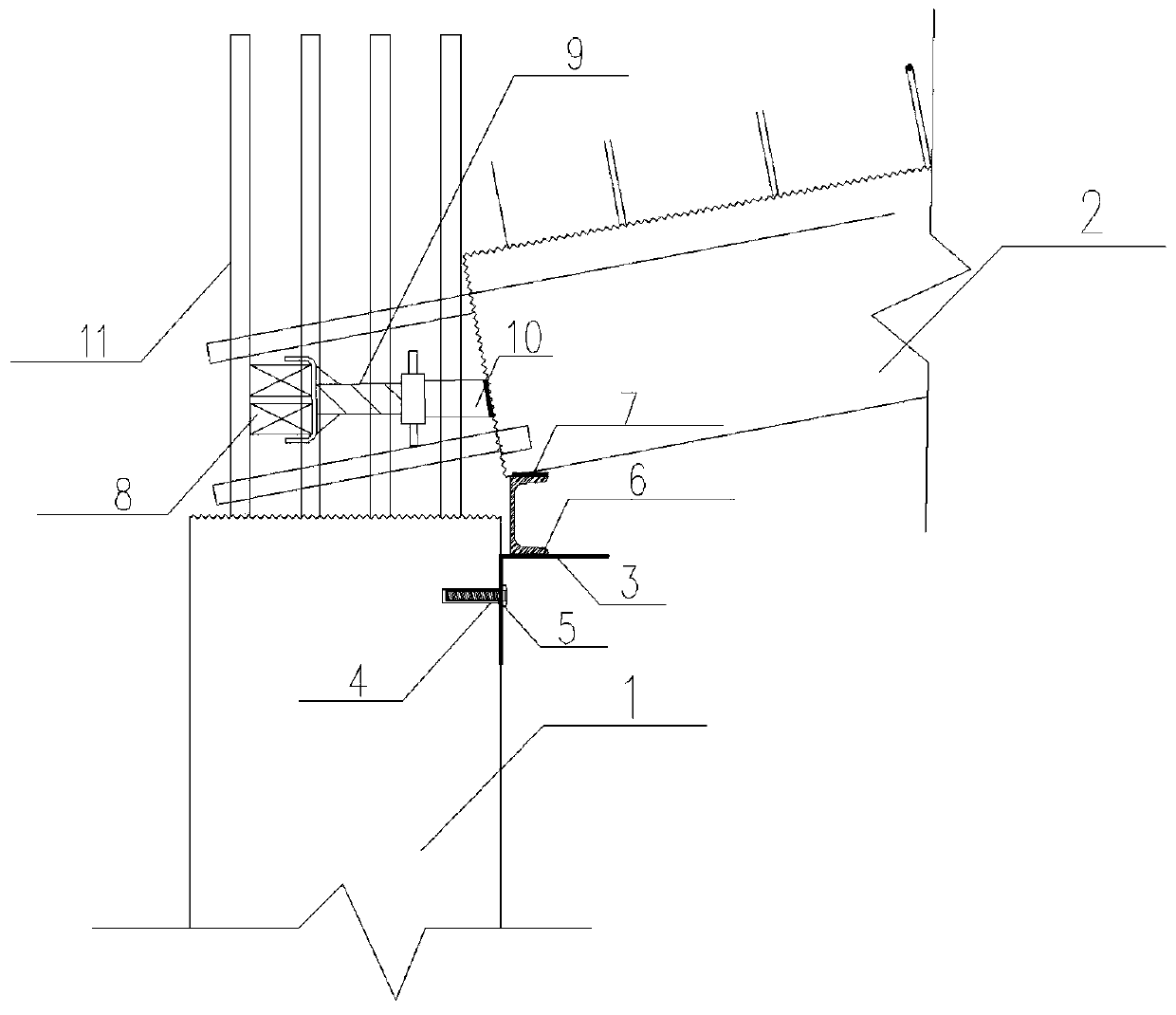

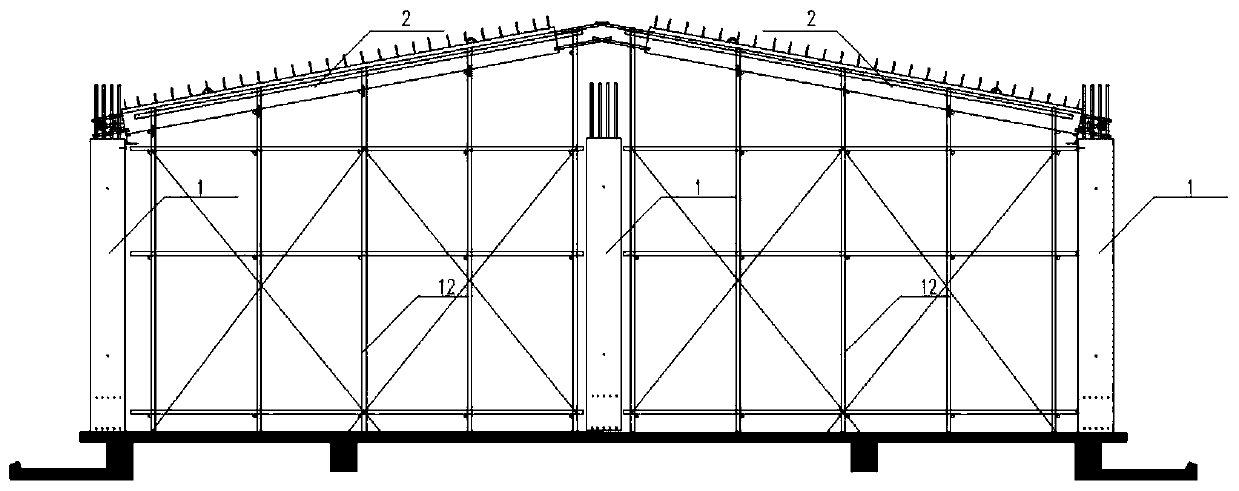

[0031] Combine below Figure 1 to Figure 3 , Describe in detail the structural composition of the prefabricated beam hoisting device for the prefabricated concrete structure inclined roof of the present invention.

[0032] Please refer to Figure 1 to Figure 3 , A prefabricated beam hoisting device for prefabricated concrete structure inclined roof, used to temporarily place the prefabricated beam 2 on the top surface of the prefabricated column 1. The device includes an angle steel supporting plate 3 and a supporting component. The angle steel supporting plate 3 is connected by The component is fixed on the top side of the prefabricated column 1; the support assembly includes a wooden square 8, a U-shaped adjustable support bracket 9 and a steel pipe support 10 that are fixedly connected in sequence, wherein the wooden square 8 is clamped and fixed to the outer main reinforcement of the precast column 1 At the top, the end of the steel pipe support 10 and the center of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com