Distribution structure of heating gas outlets in vertical flame path partition walls

A technology of heating gas and vertical fire channel, which is applied in the field of coke oven, can solve the problems of high temperature of the furnace wall of the carbonization chamber, reduce the service life of the coke oven wall, damage the masonry of the coke oven wall, etc., and achieve the improvement of heating uniformity, Good economic and environmental benefits, and the effect of reducing consumption and nitrogen oxide generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

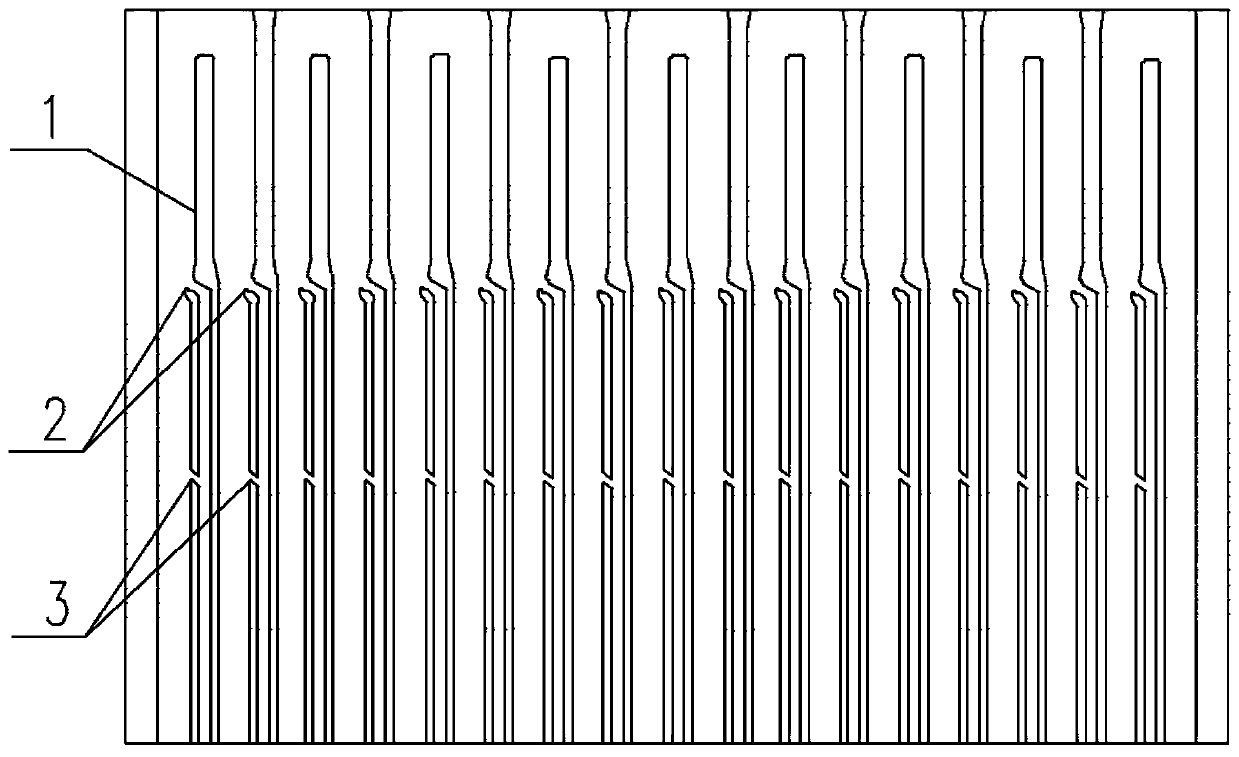

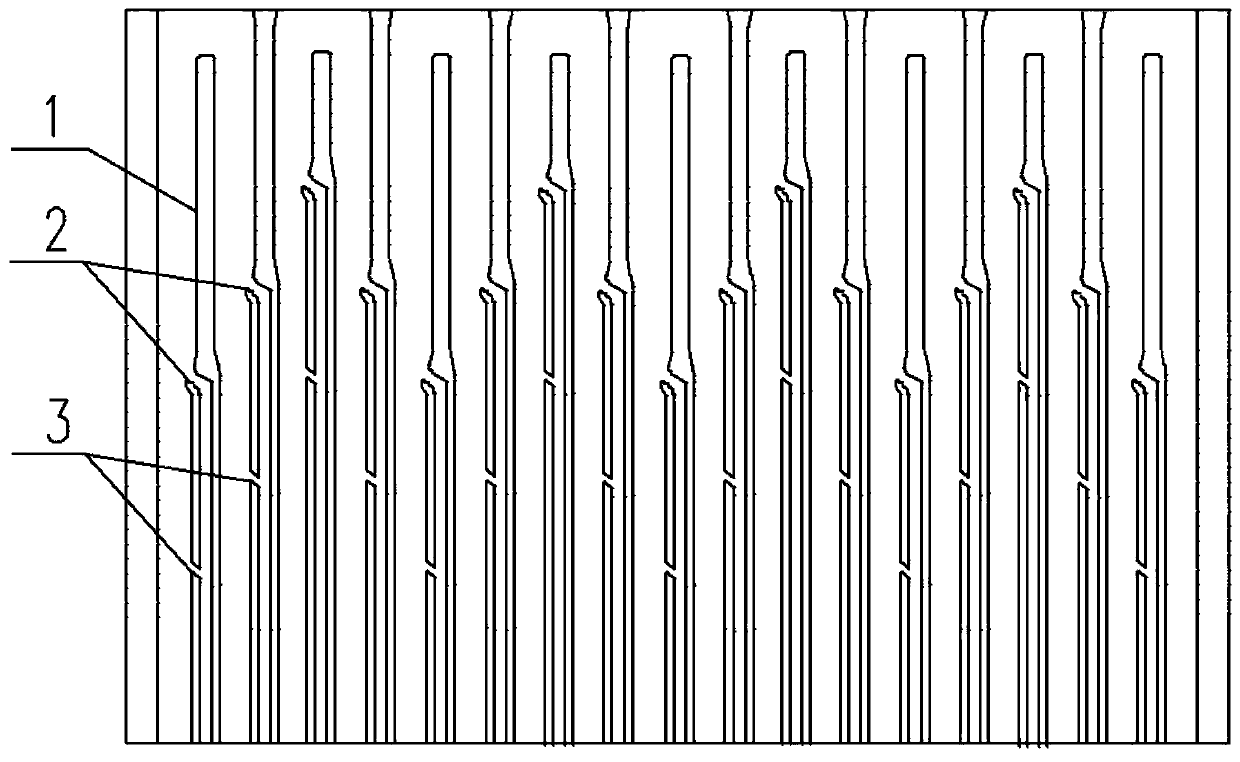

[0021] Such as figure 2 As shown, the distribution structure of the heating gas outlet on the partition wall of a kind of fire passage according to the present invention, the partition wall 1 of the fire passage is provided with a plurality of heating gas outlets along the height direction, and the partition wall 1 of different fire passages The number of heated gas outlets is the same and corresponds to each other; the heights of the corresponding heated gas outlets on different vertical fireway partition walls 1 are different.

[0022] Along the transverse direction of the coke oven, the heights corresponding to the heating gas outlets on each vertical flue partition wall 1 have a regular and continuous variation trend.

[0023] Along the transverse direction of the coke oven, the height of the flue partition wall 1 corresponding to the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com