Fast pyrolysis furnace and pyrolysis method

A pyrolysis furnace, fast technology, applied in the field of pyrolysis, can solve the problems of heating only a few degrees to tens of degrees per second, uneven heating in the high direction of the pyrolysis furnace, and affecting the yield of pyrolysis products, so as to improve the thermal efficiency solution efficiency and thermal efficiency, improve heating uniformity, and reduce the effect of NOx formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] The process of pyrolysis according to the pyrolysis furnace in the above-described embodiment is as follows.

[0062] Anhydrous coal crushed to a particle size of less than 0.5mm enters the rapid pyrolysis furnace through the coal feed inlet 7, and is evenly distributed into the pyrolysis chamber 1 through the coal feed distributor 8. The coal feeds in the pyrolysis furnace from top to bottom. The pyrolysis was completed during the settling process, and the pyrolysis time was 5 seconds.

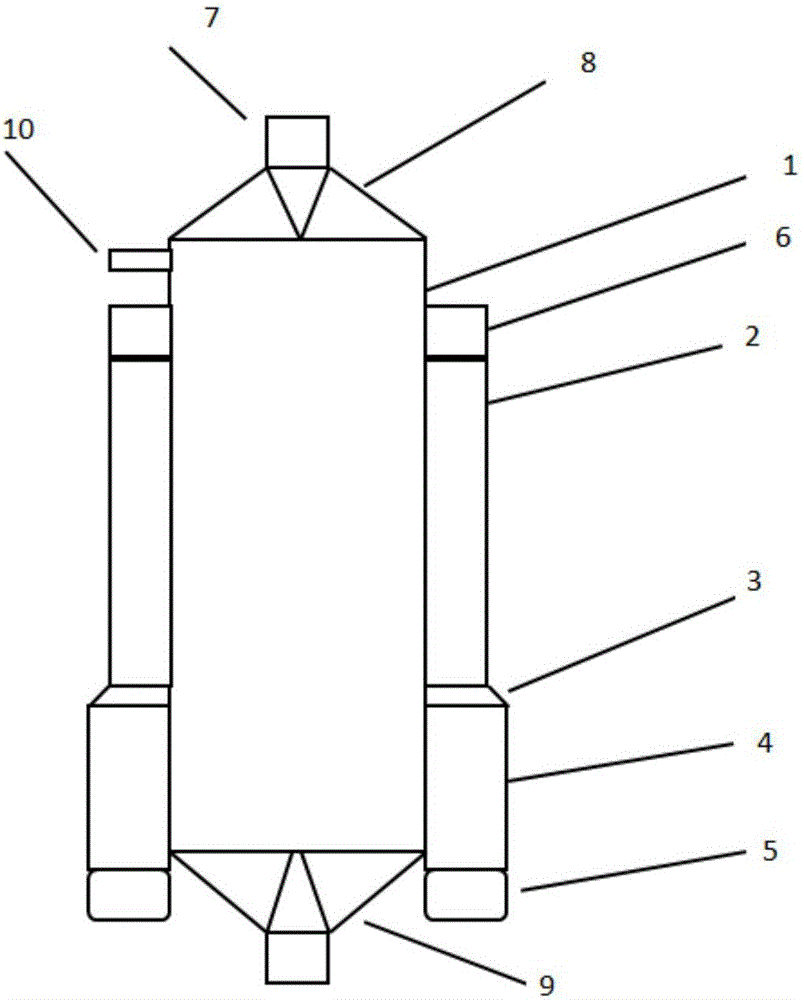

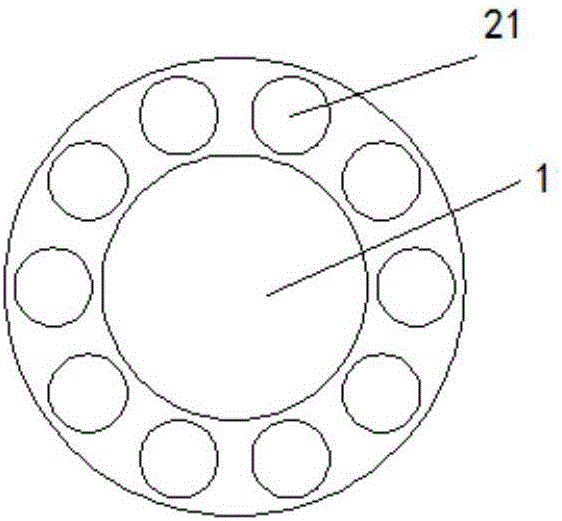

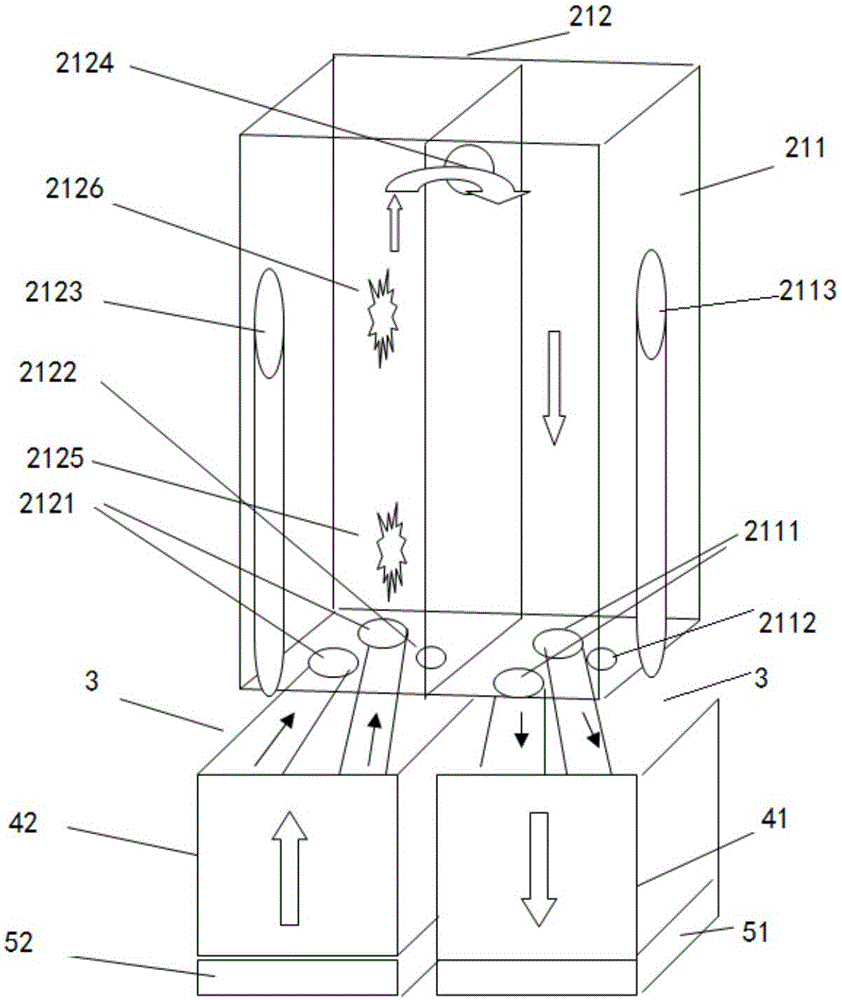

[0063] like figure 1 As shown, the heat required for rapid pyrolysis is provided by the heating system of the rapid pyrolysis furnace. The heating system includes: a combustion chamber 2, a chute 3, a regenerator 4, a furnace roof 6 and a small flue 5; the combustion chamber 2 surrounds Pyrolysis chamber 1 circle.

[0064] This embodiment includes 32 risers. The combustion chamber 2 is connected to the regenerator 4 through the chute 3 . One end of the regenerator 4 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com