Regulation method for low-nitrogen emission of reheating coke oven

An adjustment method and a reheating technology, which are applied in the heating of coke ovens, combustible gas heating coke ovens, coke ovens, etc., can solve the problems of complex coke oven structure, time-consuming and laborious, etc., to reduce the area of high temperature area and improve heating The effect of uniformity and reduction of the formation of nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

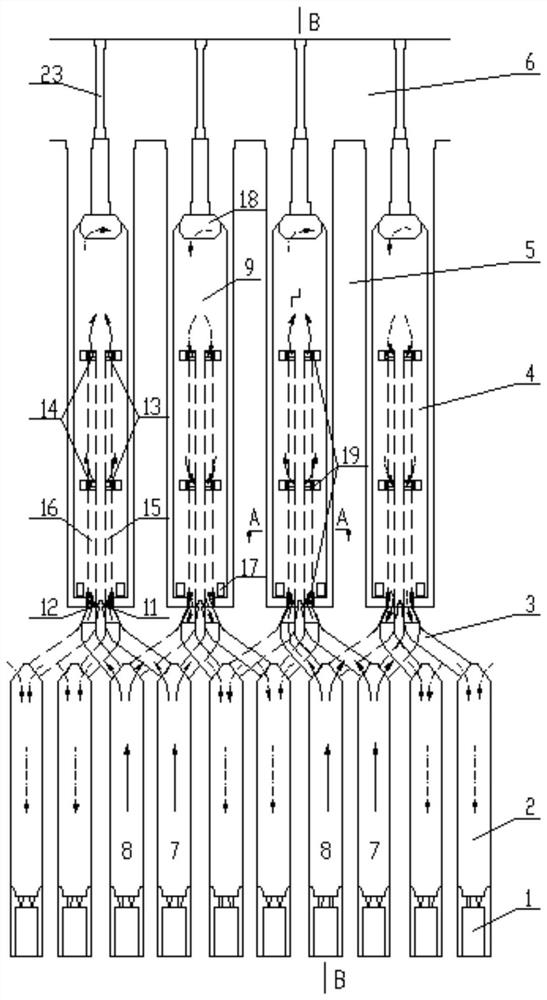

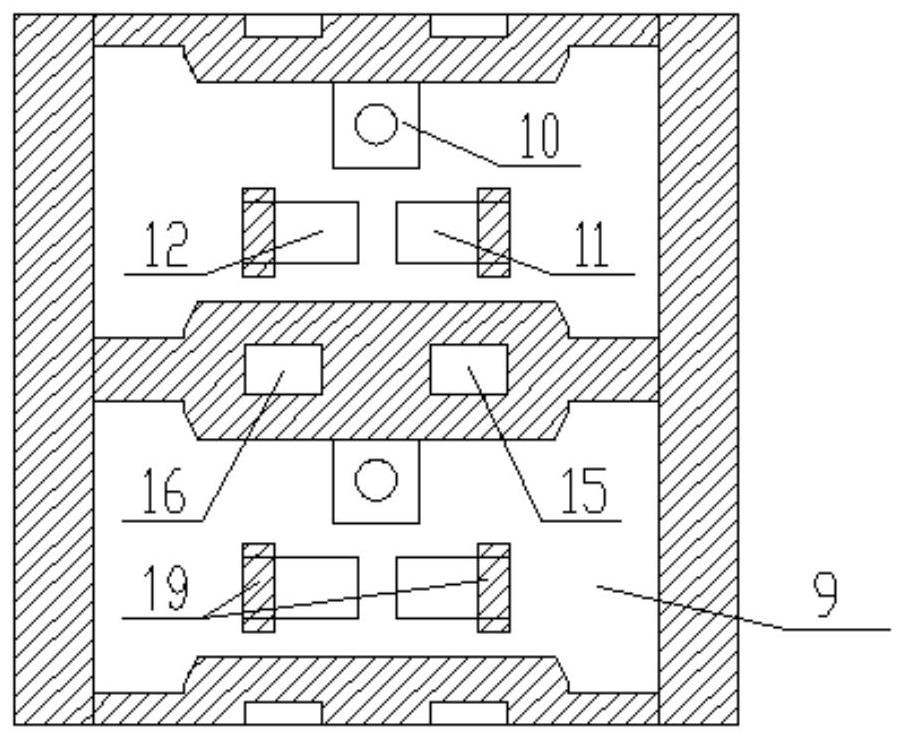

[0057] Such as Figure 1 ~ Figure 3 As shown, it is a structural schematic diagram of a common domestic reheating coke oven heating system in which both air and gas are segmented. The reheating coke oven includes a small flue 1, a regenerator 2, The chute 3, the combustion chamber 4, the carbonization chamber 5 and the furnace roof 6, and the entrance of the small flue 1 are provided with a small flue connecting pipe 22, which can adjust the air volume and gas volume entering the regenerator. Combustion chamber 4 is made up of 34 standing fire passages 9, adopts the form of double-connected fire passages, waste gas circulation, poor coal gas and air, and 9 standing fire passages are divided into three sections for heating. The bottom of the fire passage is respectively provided with an air outlet 11 at the bottom of the fire passage and a lean gas outlet 12 at the bottom of the fire passage, and two air outlets 13 and 2 for the partition wall of the fire passage are respective...

Embodiment 2

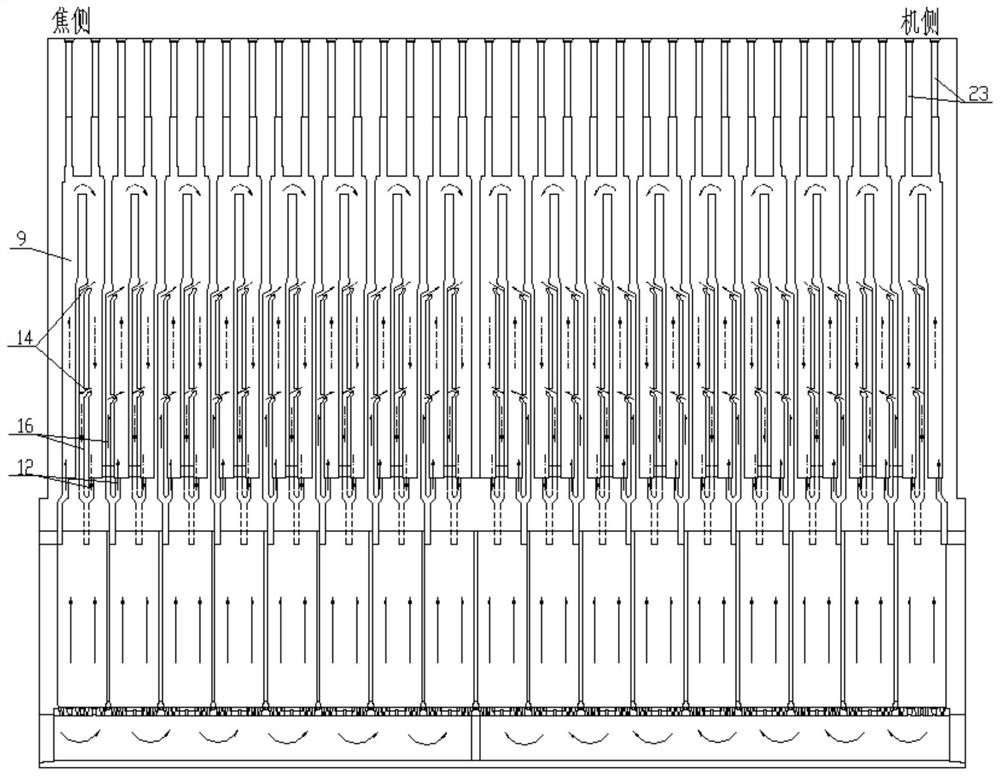

[0062] Such as Figure 7 ~ Figure 9 As shown, it is a structural schematic diagram of a common domestic air-segmented, lean-gas non-segmented reheating coke oven heating system. The reheating coke oven includes a small flue 1 and a regenerator from bottom to top 2. The chute 3, the combustion chamber 4, the carbonization chamber 5, and the furnace roof 6. A small flue connecting pipe 22 is provided at the entrance of the small flue 1, which can adjust the amount of air and gas entering the regenerator. Combustion chamber 4 is made up of 36 vertical fire passages 9, adopts the form of double fire passage, waste gas circulation, air segmentation, lean coal gas non-segmentation, and vertical fire passage 9 is divided into three stages of heating. The bottom of the fire passage 9 is respectively provided with an air outlet 11 at the bottom of the fire passage and a lean gas outlet 12 at the bottom of the fire passage. The reheating coke oven can be heated with lean gas or rich ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com