Industrial wastewater incineration treatment system and process

A technology for industrial wastewater and treatment systems, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as corrosion of refractory materials, slagging on the surface of heat exchange tubes, lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] It should be noted that the terms "first" and "second" in the description and claims of the present invention and the above drawings are used to distinguish similar objects, but not necessarily used to describe a specific sequence or sequence. It is to be understood that the data so used are interchangeable under appropriate circumstances such that the embodiments of the invention described herein can be practiced in sequences other than those illustrated or described herein. In addition, the terms "comprising" and "having" and any variations thereof in the embodiments of the present invention are intended to cover a non-exclusive inclusion, for example, a process, method, system, product or device comprising a series of steps or units is not necessarily limited to Those steps or elements are not explicitly listed, but may include other steps or elements not explicitly listed or inherent to the process, method, product or apparatus.

[0027] It is to be understood that ...

Embodiment 1

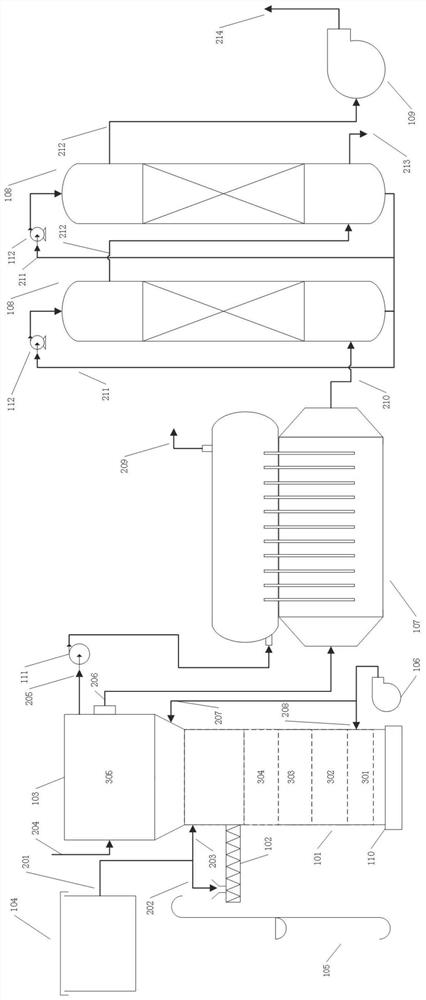

[0051] A semi-coke wastewater incineration treatment system. Such as figure 1As shown, the gasification and incineration device 101 that burns agricultural and forestry waste Salix salix (a sand control plant that requires regular stubble and rejuvenation) has a designed fuel consumption of 2 tons / hour after receiving Kisalis salix; the main body of the gasification and incineration device 101 The height is 8.5m from the lower edge of the sleeve of the feeder 102 to the upper edge of the slag discharger 110. The bucket elevator 105 is used to lift the fuel from the ground to the silo of the feeder 102; the inner diameter of the main body of the gasification incinerator 101 is the oxidation Zone 301, reduction zone 302, carbonization zone 303 or drying zone 304 have a furnace cross-sectional inner diameter of 2.6m; the furnace in the oxidation zone 301 and reduction zone 302 adopts a water-cooled jacket structure, and the furnace in the carbonization zone 303 and drying zone 30...

Embodiment 2

[0053] The invention relates to a semi-coke waste water incineration treatment process. Such as figure 1 As shown, the gasification and incineration device 101 that burns agricultural and forestry waste Salix salix has a fuel consumption of 2 t / h, the operating temperature of the oxidation zone 301 is 890°C, the temperature of the airflow above the drying zone is 110°C, and the temperature of the incineration zone is 1100°C , primary air duct 208 air volume 2100m 3 / h, secondary air duct 207 air volume 8050m 3 / h, the outlet water temperature of the water-cooled combustion chamber 103 jacket is 85°C, the low-temperature flue gas pipe 210 shows the flue gas outlet temperature of the boiler 107 is 142°C, and the normal temperature flue gas pipe 212 shows the flue gas temperature at the outlet of the multi-stage water washing spray tower 108 is 45°C . The semi-coke wastewater raw water from the waste water pool 104 enters the drying area 304 of the gasification incinerator 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com