Multi-stage adjustable low-nitrogen gas burner suitable for coke oven gas

A gas burner and coke oven gas technology, which is applied to gas fuel burners, burners, combustion types, etc., can solve the problems of poor fuel grading, fuel accumulation, and high emissions, and achieves low manufacturing cost, simple structure, and NOx suppression. generated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

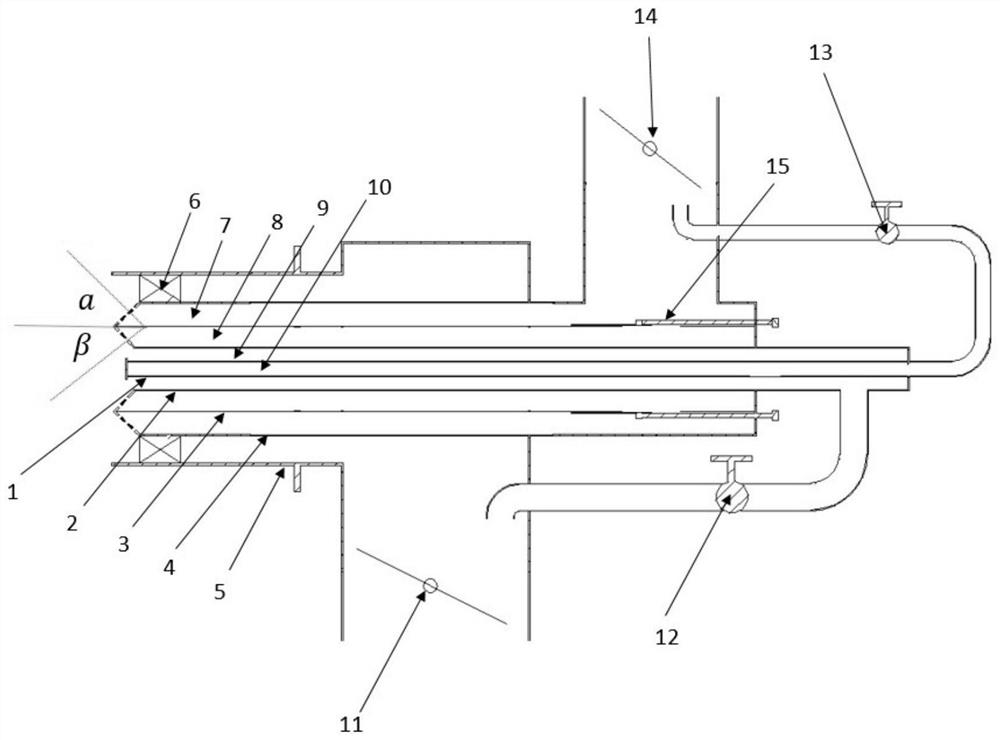

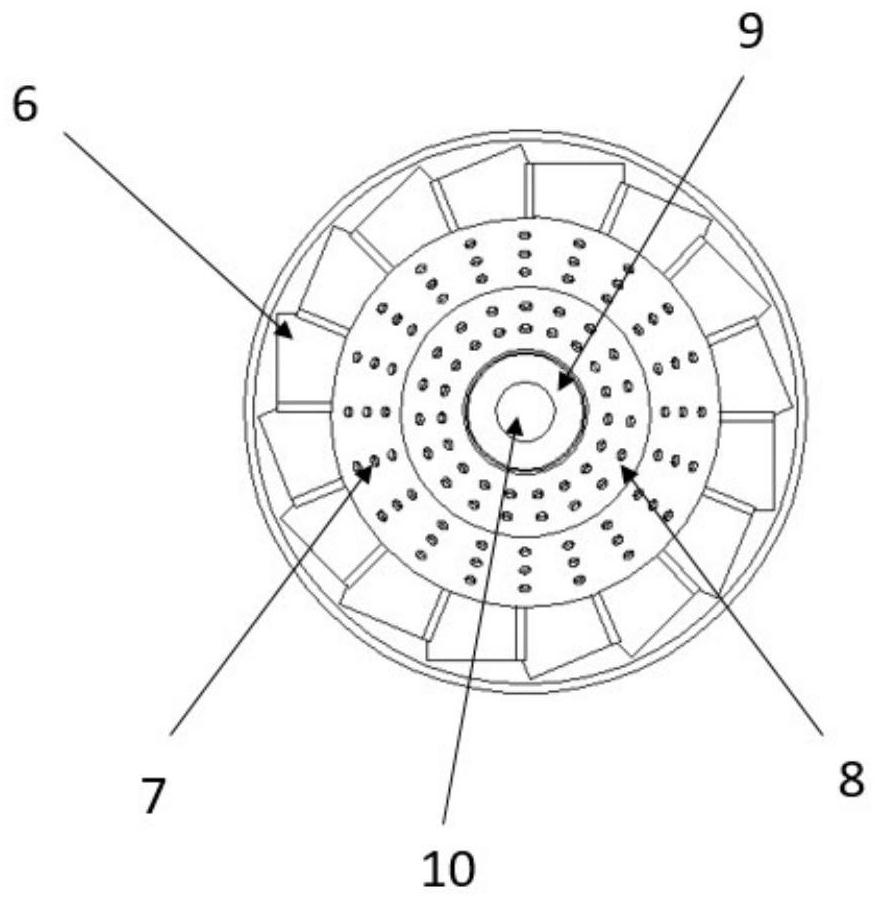

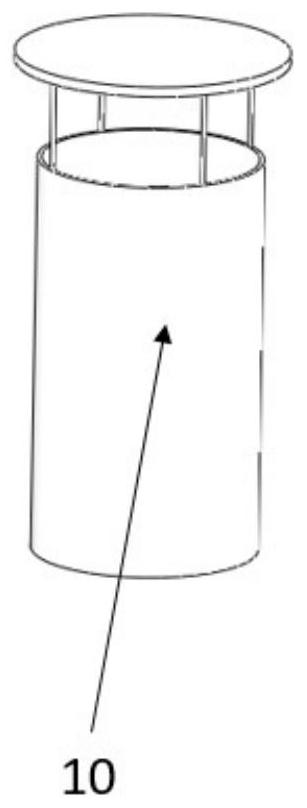

[0021] refer to Figure 1 to Figure 3 , the present invention is applicable to coke oven gas multi-stage adjustable low-nitrogen gas burner including central fuel cylinder 1, central air cylinder 2, primary fuel cylinder 3, secondary fuel cylinder 4 and combustion The container shell 5, wherein, the center fuel area 10 is formed inside the center fuel cylinder 1, the annular central wind area 9 is formed between the central fuel cylinder 1 and the central air cylinder 2, and the annular central wind area 9 is formed between the central air cylinder 2 and the primary fuel cylinder 3 The primary fuel area 8, the annular secondary fuel area 7 is formed between the primary fuel cylinder 3 and the secondary fuel cylinder 4, and the annular swirling wind area 6 is formed between the secondary fuel cylinder 4 and the burner case 5; A swirl device is arranged between the fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com