Concrete prefabricated sewage inspection well convenient to install and connect

A convenient installation and concrete technology, which is applied to waterway systems, water supply devices, drainage structures, etc., can solve the problems of increasing costs, cracking of sewage inspection wells, increasing cost waste, etc., and achieve the effect of increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

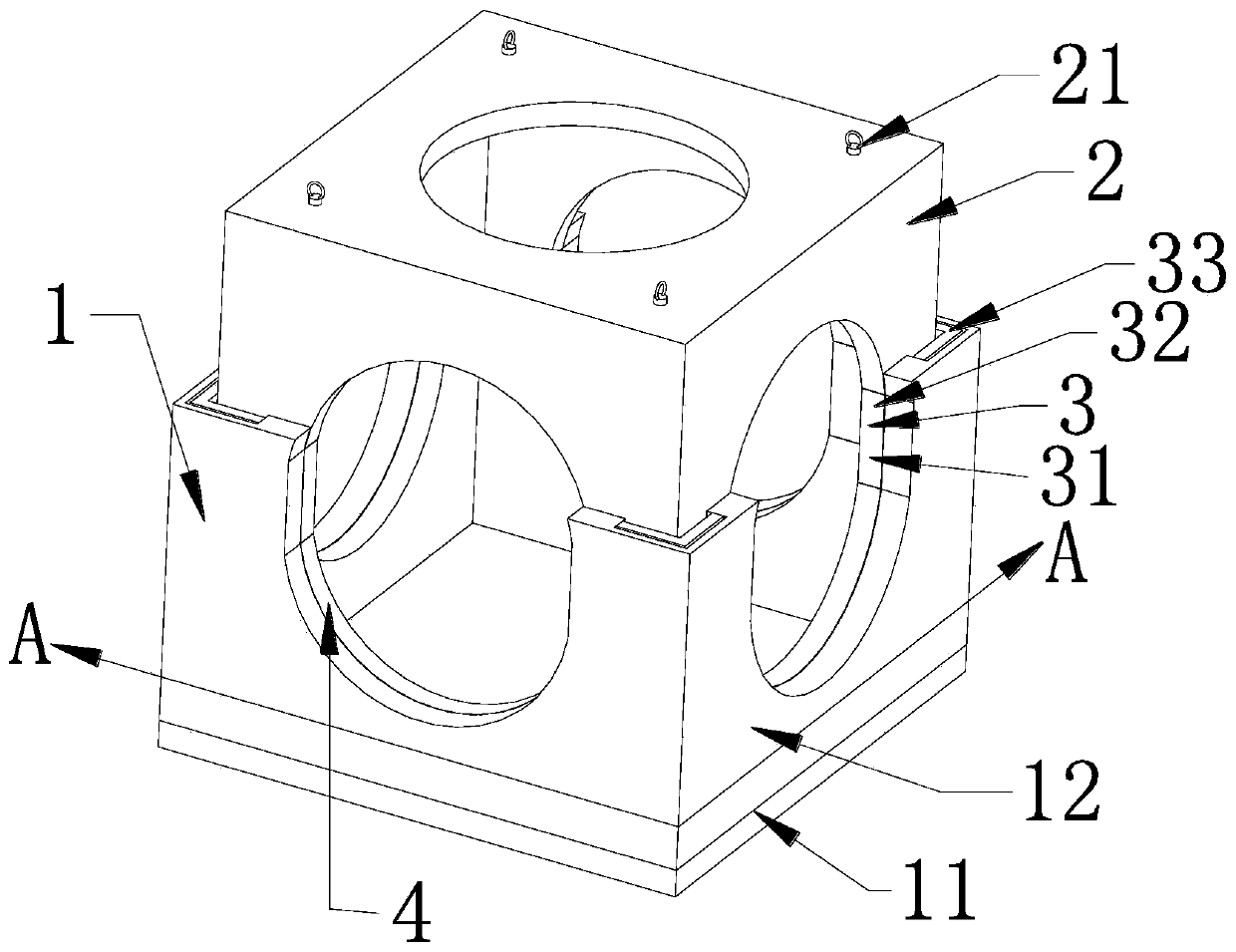

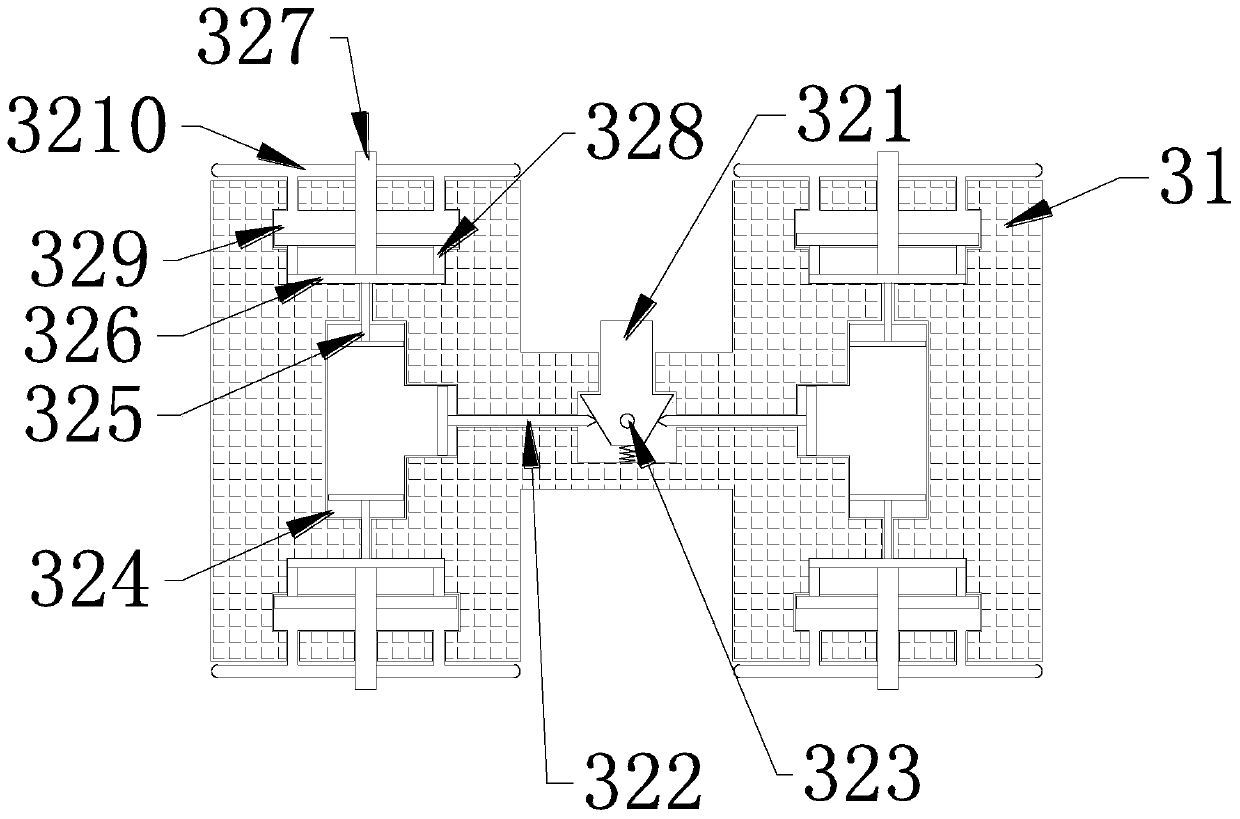

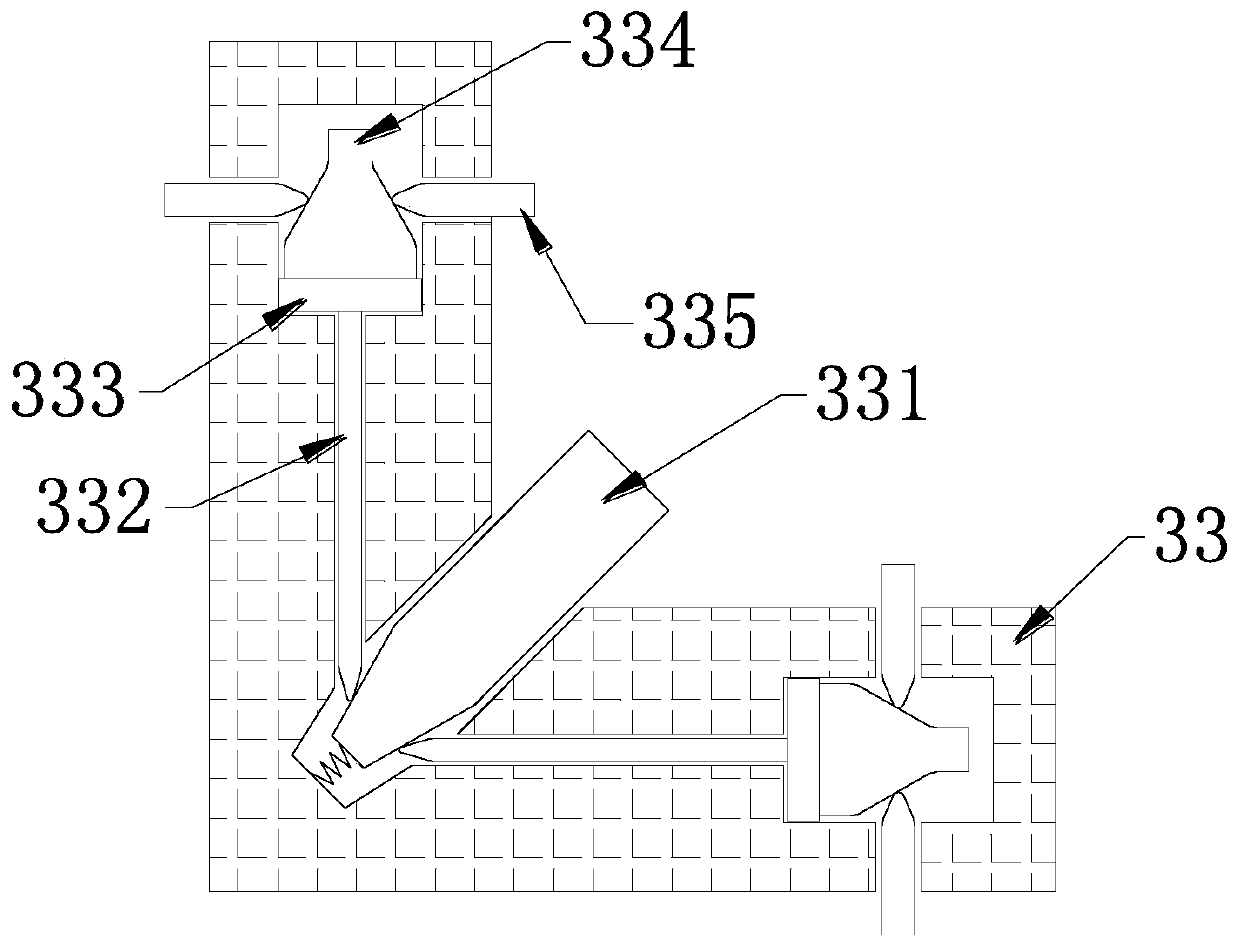

[0025] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 5 , to further elaborate the present invention.

[0026] A concrete prefabricated sewage inspection well that is convenient for installation and connection, including a mounting base 1, an upper cover plate 2, a connecting kit 3 and a lower cover plate 4, and an upper cover plate 2 and a connecting kit 3 are arranged inside the mounting base 1 sequentially from top to bottom and the lower cover plate 4, wherein:

[0027] The mounting base 1 includes a support base 11 and a firm plate 12. The support base 11 is fixed on the ground by means of cement, and chute A is evenly arranged around the support base 11, and the surrounding corners of the support base 11 are uniformly welded. A firm plate 12 is provided, and blind holes A are uniformly arranged on the firm plate 12 .

[0028] Blind holes B are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com