Three-burning-rate variable-thickness combined propellant grain structure of nozzleless rocket motor

An engine and variable thickness technology, which is applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problem of insufficient internal energy conversion of gas kinetic energy, etc., and achieve the effect of improving the acceleration effect, simple shape, and low application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

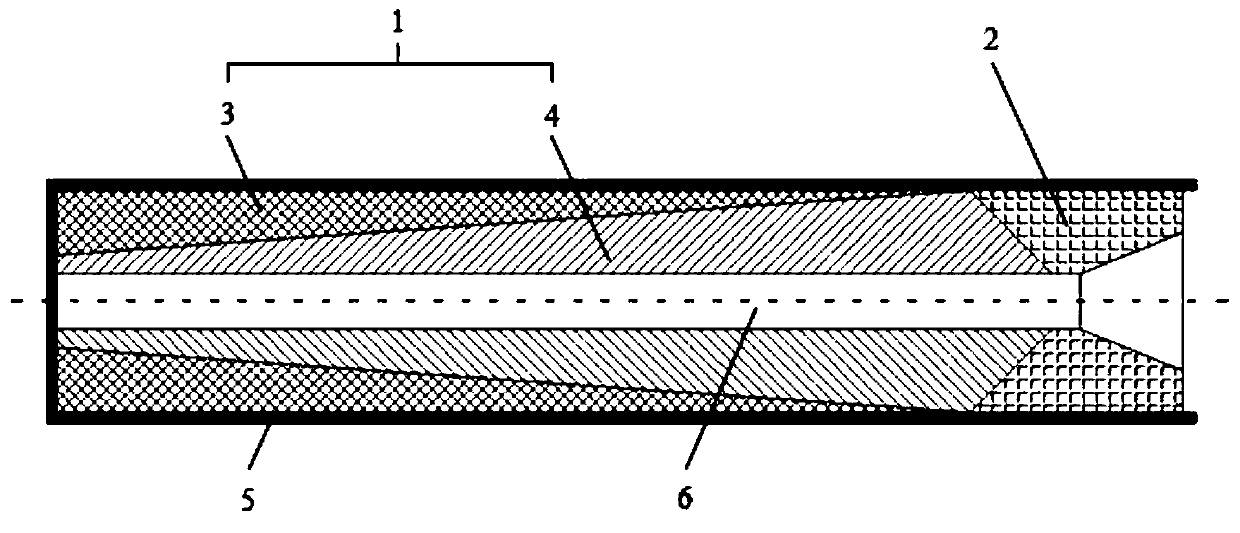

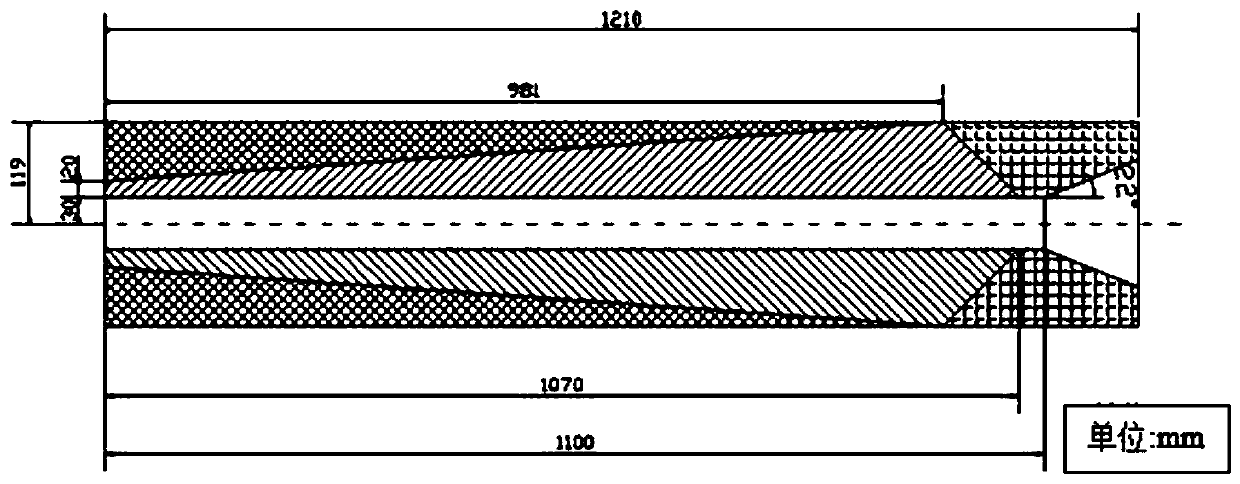

[0027] combine figure 1 , taking the whole working process of the nozzle-less engine from ignition as an example, the nozzle-less engine powder includes main powder 1 and nozzle powder 2; the main powder 1 includes high-burning-velocity powder 3 and The medium burning rate grain 4, the outer surface of the high burning rate grain 3 is bonded to the inner wall 5 of the engine combustion chamber, the outer diameter of the medium burning rate grain 4 is bonded to the inner hole of the high burning rate grain 3, The fitting surface is funnel-shaped with an opening outward;

[0028] The outer surface of the nozzle grain 2 is bonded to the combustion inner wall 5 of the engine;

[0029] The tail of the main charge 1 is closely attached to the head of the nozzle charge 2, and the fitting surface is funnel-shaped with an opening along the axis inwards.

[0030] Described high burning rate grain 3, medium burning speed grain 4, nozzle grain 2, and engine combustion inner wall 5 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com