Series diaphragm pump with non-return and anti-seepage functions

A technology of anti-leakage and diaphragm pumps, which is applied to pumps with flexible working elements, parts of pumping devices for elastic fluids, pumps, etc., which can solve the problem of poor ability of umbrella valves to pass foreign matter and easy adsorption of umbrella valves Particles, diaphragm pump can not work and other problems, to achieve the effect of high tablet loading efficiency, improved water pumping efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

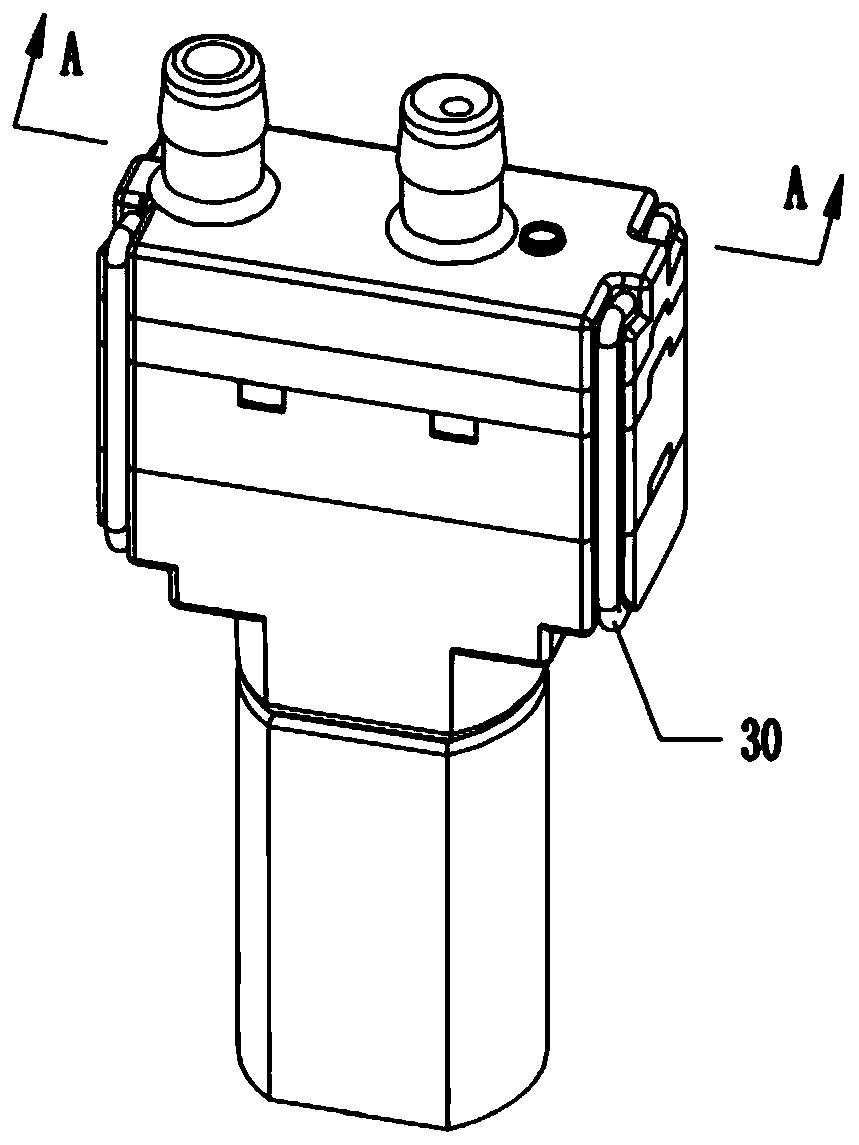

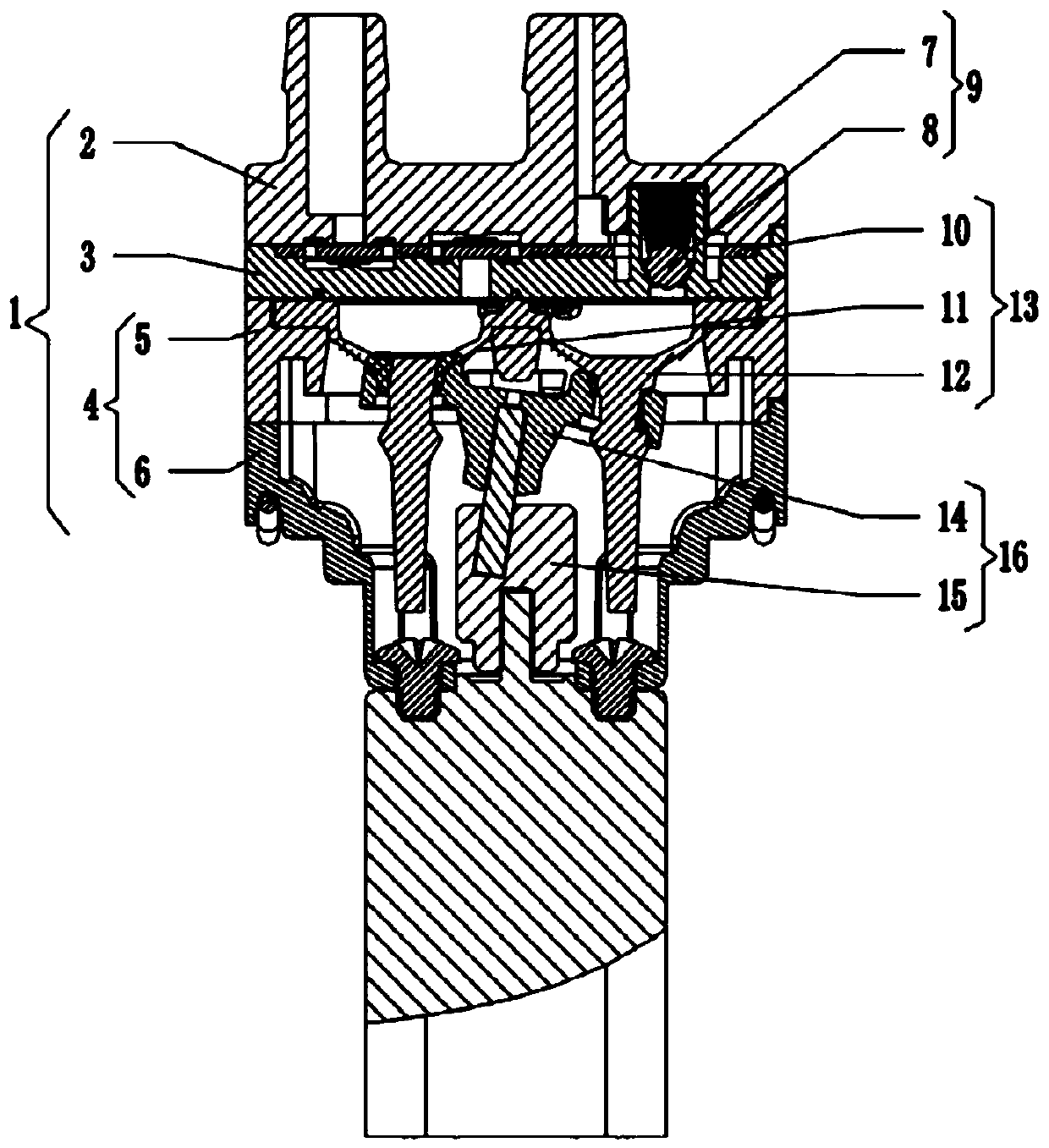

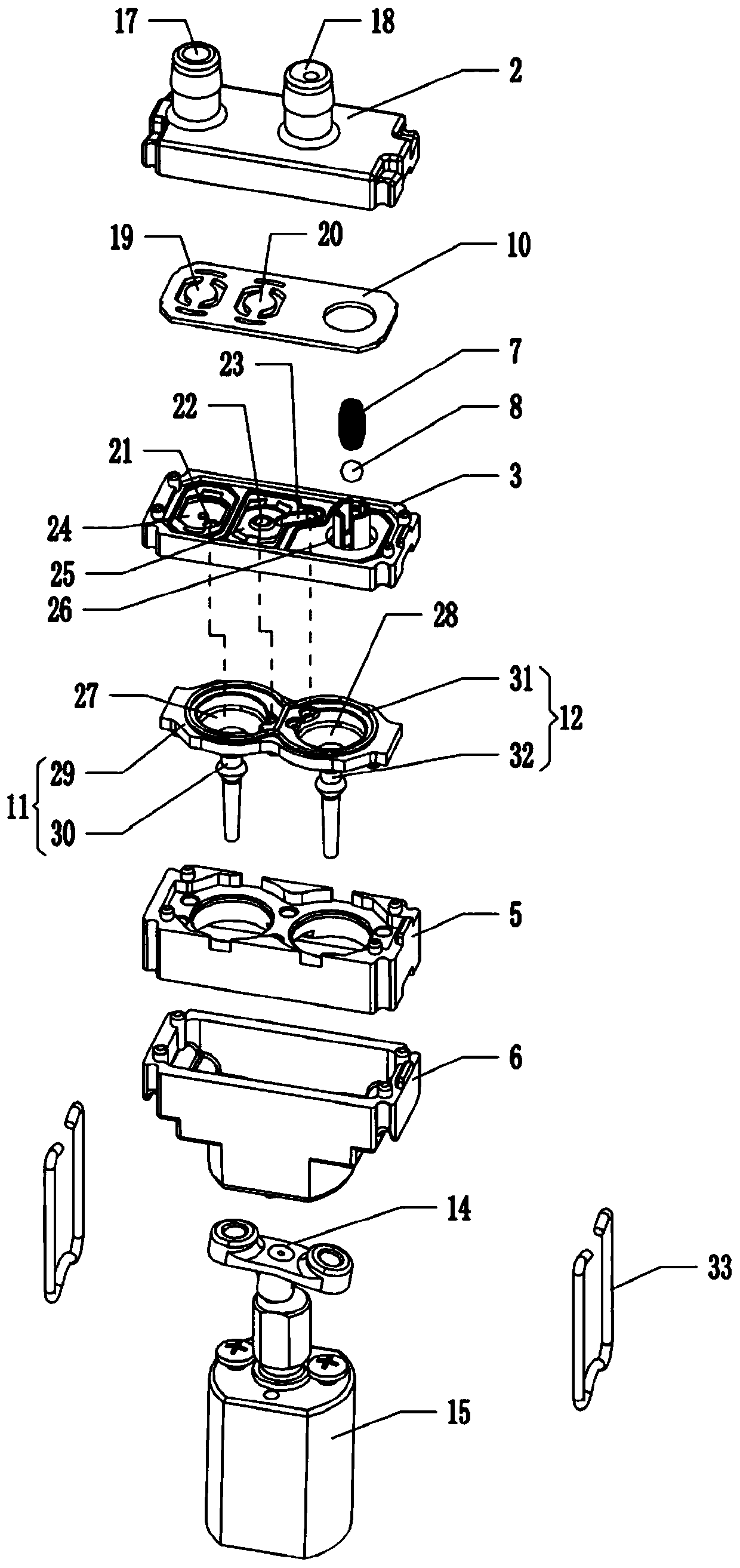

[0044] Depend on figure 1 , figure 2 and image 3 As shown, in this embodiment, a series diaphragm pump with check and anti-leakage functions includes:

[0045] The housing mechanism 1 includes a support assembly 4, a diaphragm seat 3 supported on the support assembly 4, and an upper cover 2 supported on the diaphragm seat 3 and provided with an inlet channel 17 and an outlet channel 18; the upper cover 2 and the diaphragm seat 3 sandwich the first chamber 24, the second chamber 25 and the third chamber 26, the liquid inlet channel 17 can be connected with the first chamber 24, and the liquid outlet channel 18 can be connected with the third chamber 26 The diaphragm seat 3 is provided with a first passage 21 communicating with the first chamber 24, and a second passage 22 and a third passage 23 communicating with the second chamber 25 respectively;

[0046] Diaphragm mechanism 13, which includes the diaphragm 10 sandwiched between the upper cover 2 and the diaphragm seat 3...

no. 2 example

[0063] Depend on Figure 6 As shown, in this embodiment, the anti-return mechanism 9 also includes a non-return ball 8 and a return spring 7 . Specifically, the upper cover 2 is provided with a movable groove 37 that is compatible with the return spring 7 and the check ball 8 , and the return spring 7 is located in the movable groove 37 . When the second movable capsule 12 moves upward, the solution in the second capsule cavity 28 pushes away the check ball 8 , allowing the check ball 8 to move upward and compress the return spring 7 . When the second movable bag 12 moves downward, the return spring 7 will drive the check ball 8 to move downward to seal the first opening 34 . Wherein, the movable groove 37 can play the role of positioning the return spring 7 . At the same time, compared with the first embodiment, the movable groove 37 of this case is a groove placed upside down on the upper cover 2, which will not accumulate foreign matter, and has a stronger ability to pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com