Cooling fan and electronic equipment

A heat dissipation fan and air outlet technology, which is applied to mechanical equipment, parts of pumping devices for elastic fluids, non-variable pumps, etc., can solve the problems of affecting system performance, high R&D costs, large manpower consumption, cost and Time and other issues, to achieve the effect of reducing noise, low noise, and solving the unbalanced flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions of the embodiments of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

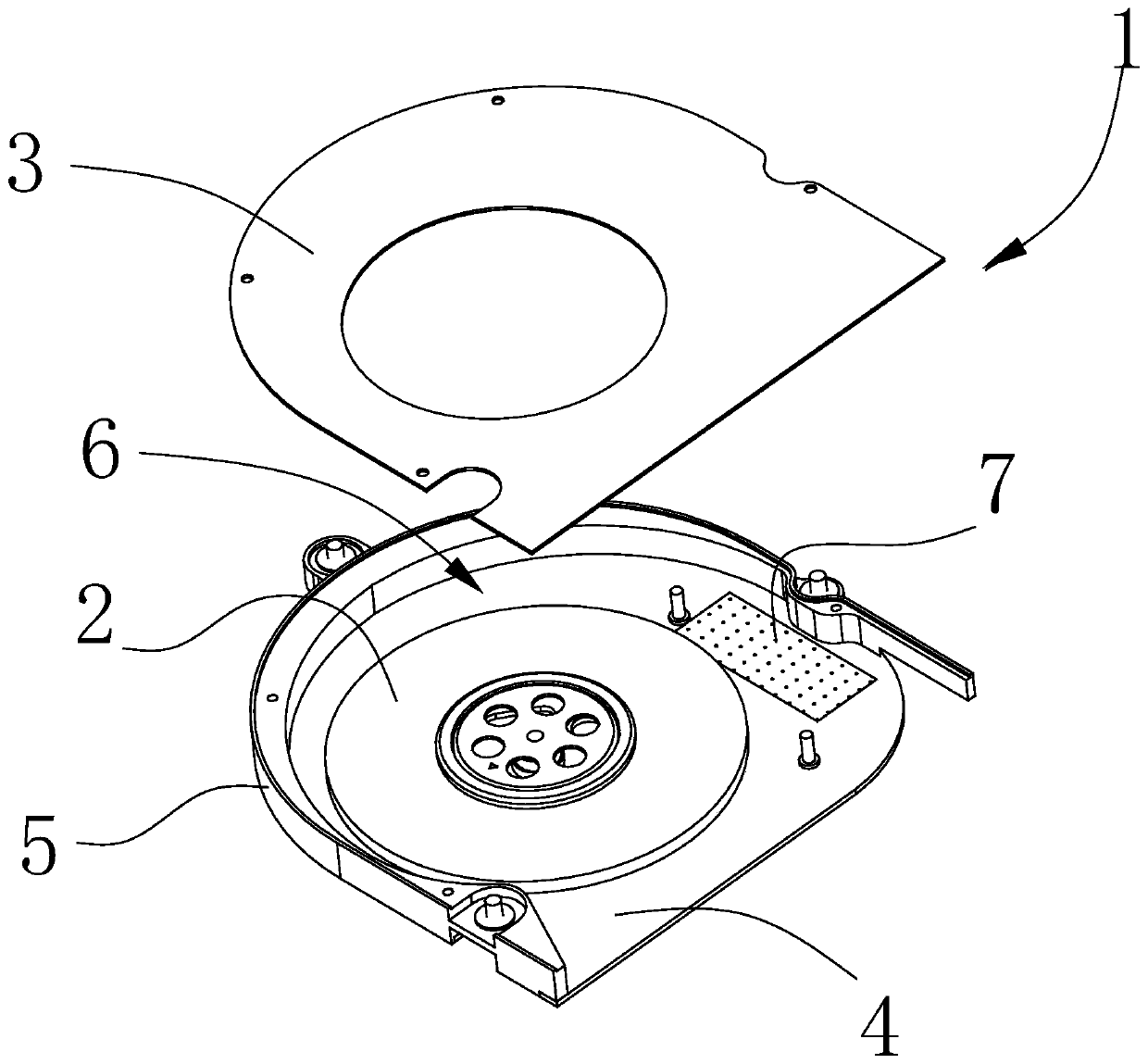

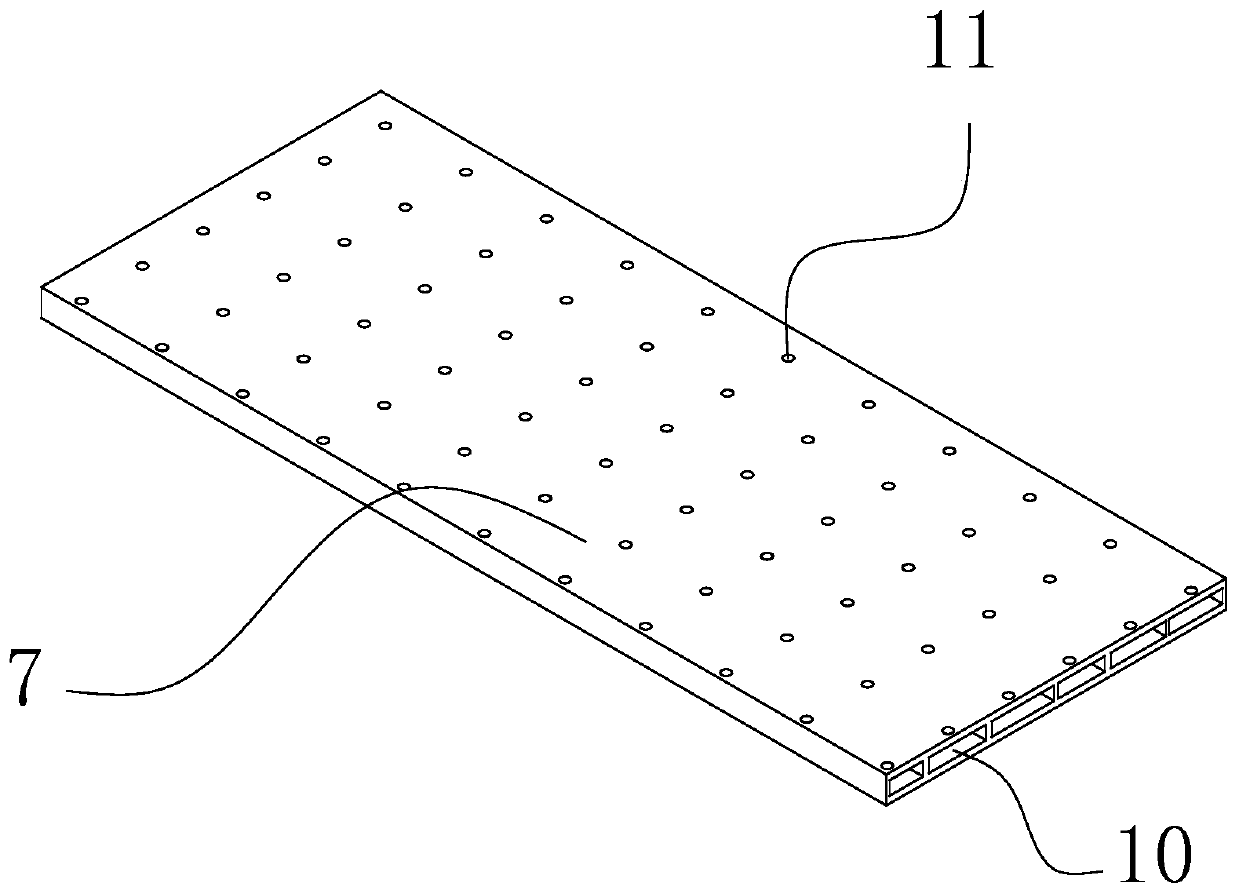

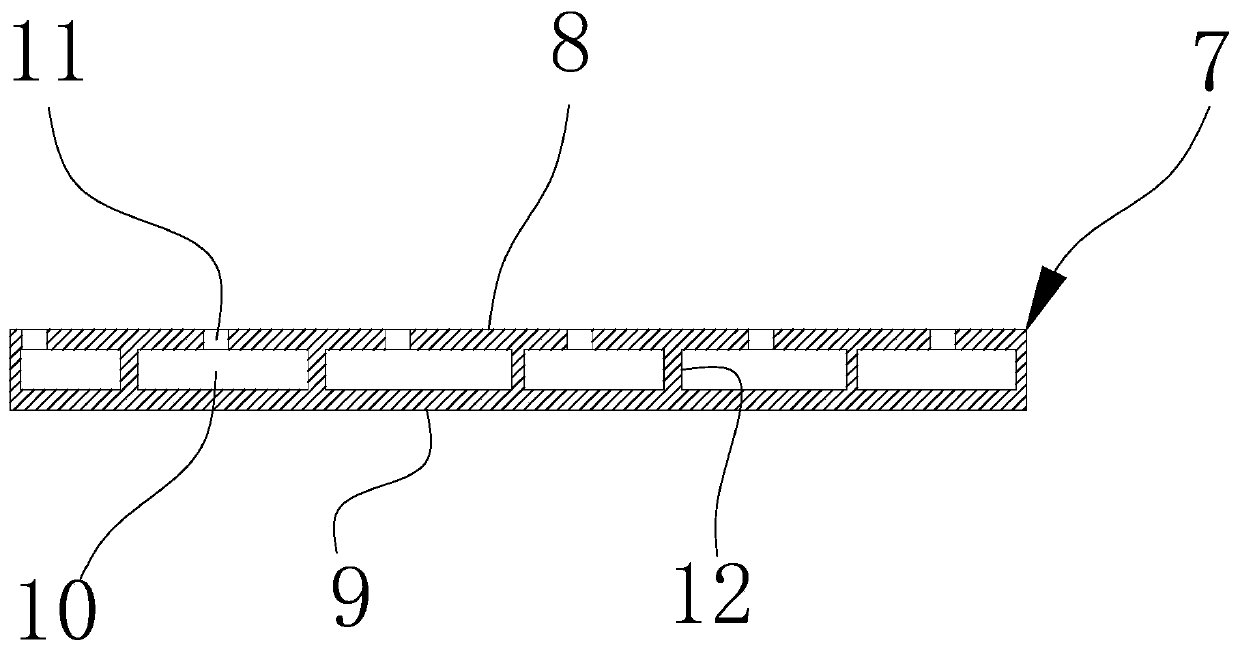

[0023] figure 1 It is a schematic diagram of the three-dimensional structure of the cooling fan according to the embodiment of the present invention, see figure 1 As shown, the cooling fan of the embodiment of the present invention includes: a casing 1 and an impeller 2, and the casing 1 includes a top plate 3 and a bottom plate 4 oppositely arranged, and a side plate enclosed between the top plate 3 and the bottom plate 4 5. The top plate 3, the bottom plate 4 and the side plate 5 enclose the inner cavity 6 of the housing 1, the impeller 2 is arranged in the inner cavity 6, the top plate 3 and the bottom plate All or part of at least one of 4 is made of a sound-absorbing board 7; the sound-absorbin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap