Helium flame-retardant sealing structure for liquid rocket engine turbopump

A liquid rocket and sealing structure technology, applied in liquid fuel engines, rocket engine devices, machines/engines, etc., can solve problems such as explosion, oxidant and fuel contact combustion, to avoid contact combustion, safe and reliable isolation, and improve surface hardness and the effect of friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

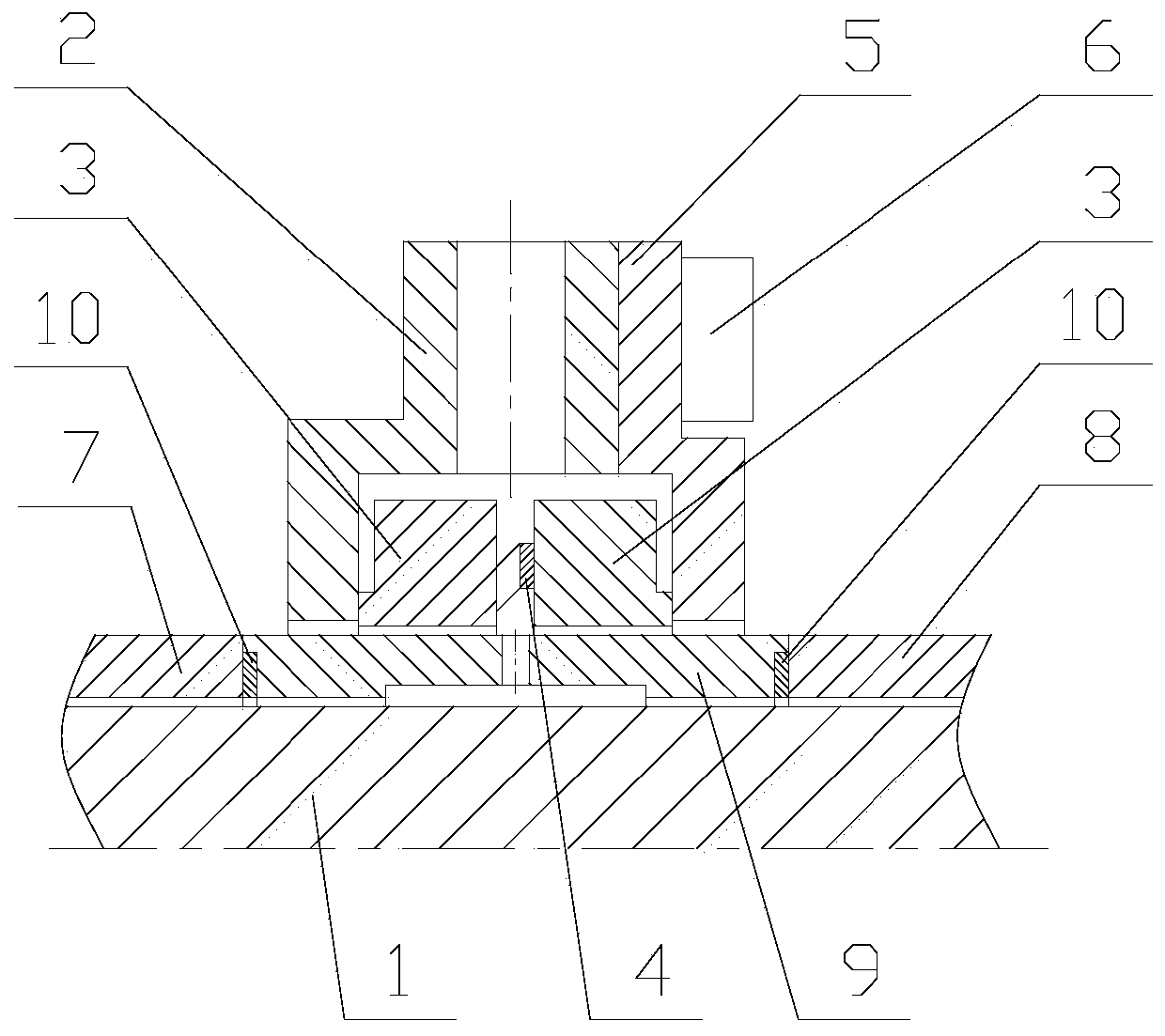

[0028] A liquid rocket engine turbopump helium flame-retardant sealing structure, including a rotating shaft 1, a sealing shell 2, a floating ring 3, a wave spring 4, a cover plate 5, a first bushing 7, a second bushing 8, and a sealing bushing 9. Aluminum pad10.

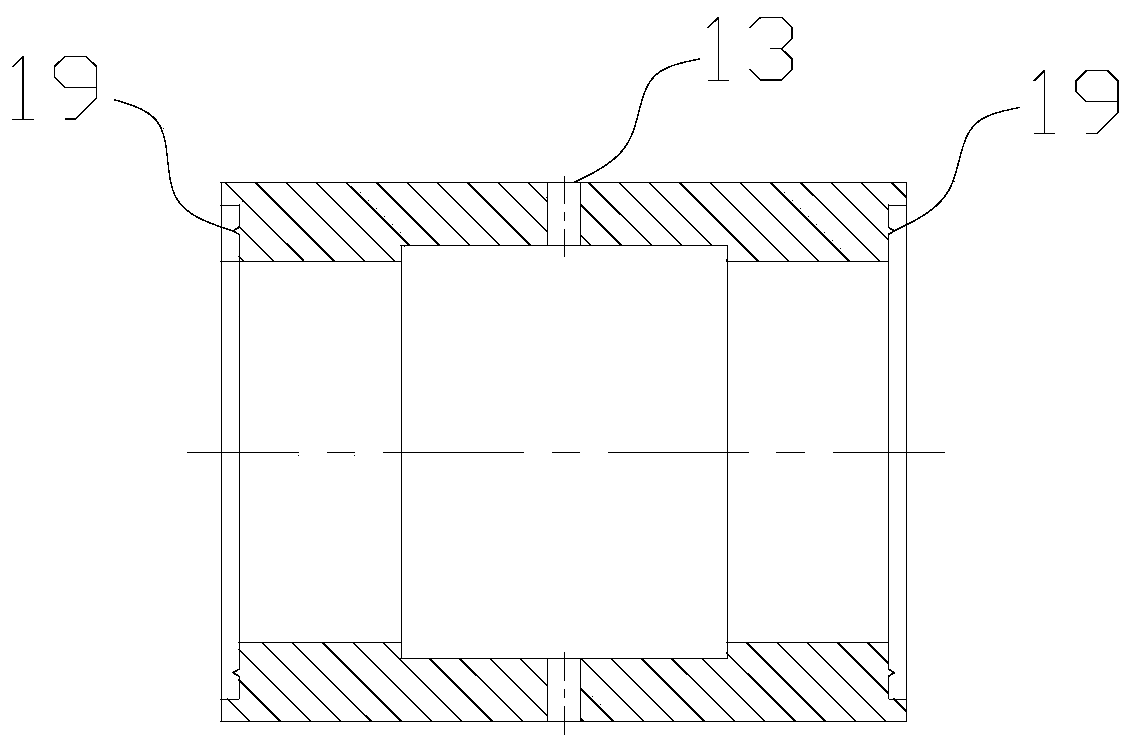

[0029] The first shaft sleeve 7, the sealing shaft sleeve 9, and the second shaft sleeve 8 are sequentially set on the rotating shaft 1, and the sealing shaft sleeve 9 is sealed and connected with the first shaft sleeve 7 and the second shaft sleeve 8; the sealing The shaft sleeve 9 is provided with an annular groove on the surface close to the rotating shaft 1. When the sealing sleeve 9 is set on the rotating shaft 1, an annular cavity 14 is formed between the annular groove and the rotating shaft 1; The annular groove is provided with 4-6 radial holes in total, and the 4-6 radial holes 13 are distributed along the circumference of the sealing sleeve 9 .

[0030] The sealing housing 2 is sleeved on the sealing sha...

Embodiment 2

[0034] A liquid rocket engine turbopump helium flame-retardant sealing structure, including a rotating shaft 1, a sealing shell 2, a floating ring 3, a wave spring 4, a cover plate 5, a screw 6, a first bushing 7, a second bushing 8, a seal Shaft sleeve 9, aluminum pad 10; Wherein floating ring 3 has two roads, as figure 1 shown.

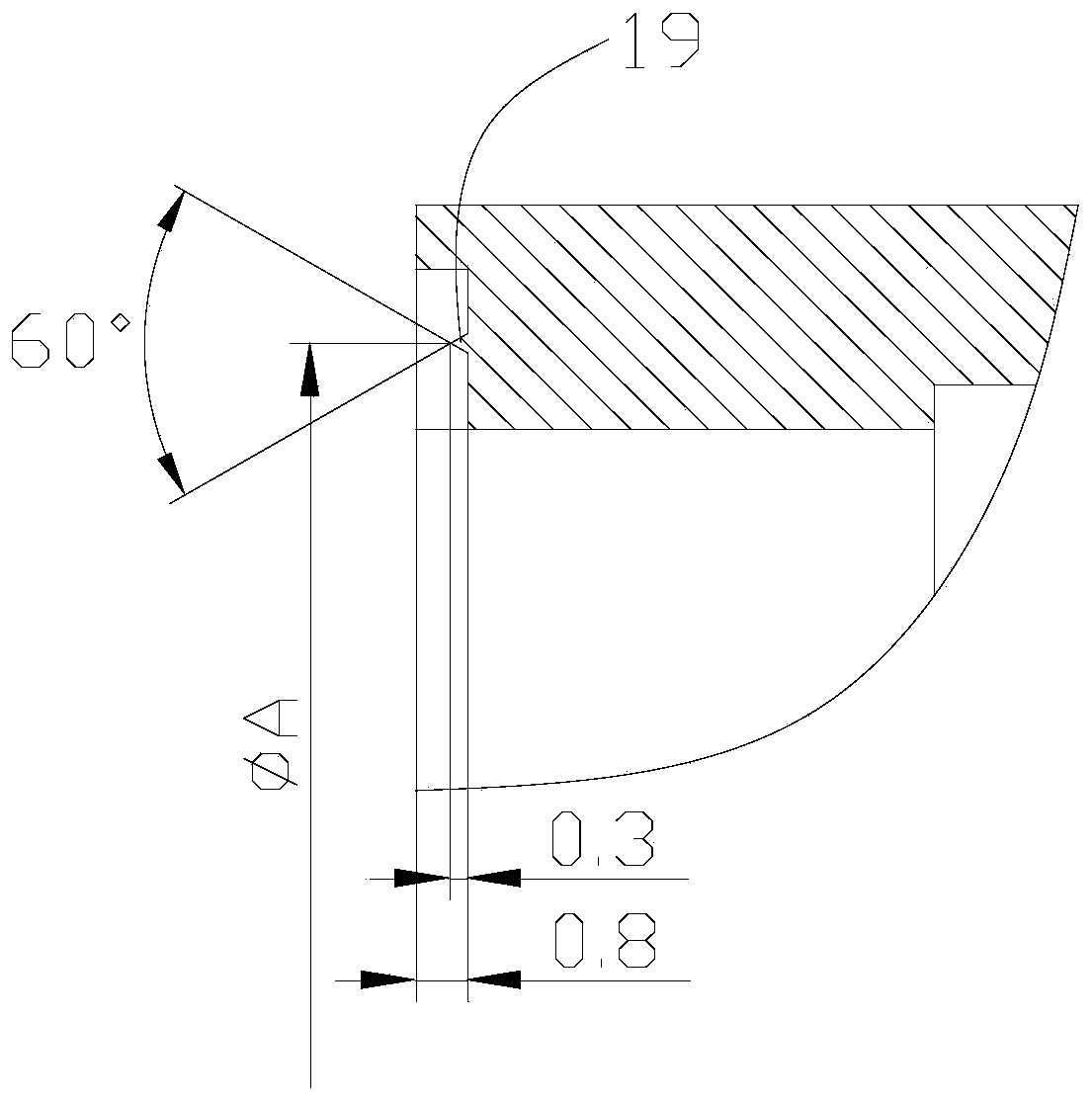

[0035] Four radial holes 13 are arranged in the middle position of the floating ring 3 corresponding to the back-to-back installation of the sealing sleeve 9, and sealing teeth 19 are arranged at both ends of the sealing sleeve 9, such as Figure 2~3 shown. The inner surface of the sealing shaft sleeve 9 is processed with an annular groove. After assembly, the sealing sleeve 9 forms an annular cavity 14 with the rotating shaft 1 . When working, the helium in the dynamic seal isolation cavity 12 enters the annular cavity 14 from the middle gap of the floating ring 3 through the radial hole 13 of the seal sleeve 9 to form a helium isolation cavity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com