Bending failure evaluation method for corrosion defect contained submarine pipeline structure

A technology for submarine pipeline and failure assessment, which is applied in the direction of testing material strength, pipeline system, weather resistance/light resistance/corrosion resistance by applying a stable bending force, and can solve problems such as inaccurate evaluation results and low practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1 Failure Assessment Method

[0064] An embodiment of the present invention provides a bending failure evaluation method for a submarine pipeline structure containing corrosion defects, specifically:

[0065] Step S1: Select an active pipeline as the pipeline to be tested, and detect the location and corrosion size of the largest corrosion defect of the pipeline under test;

[0066] Step S2: According to the service environment state parameters of the pipeline under test and the detection data of step S1, calculate the resultant force of the wave load and current load, determine the bending moment and the bending direction of the pipeline under test, and determine the pressure of the pipeline under test. The maximum bending moment position and maximum bending moment value;

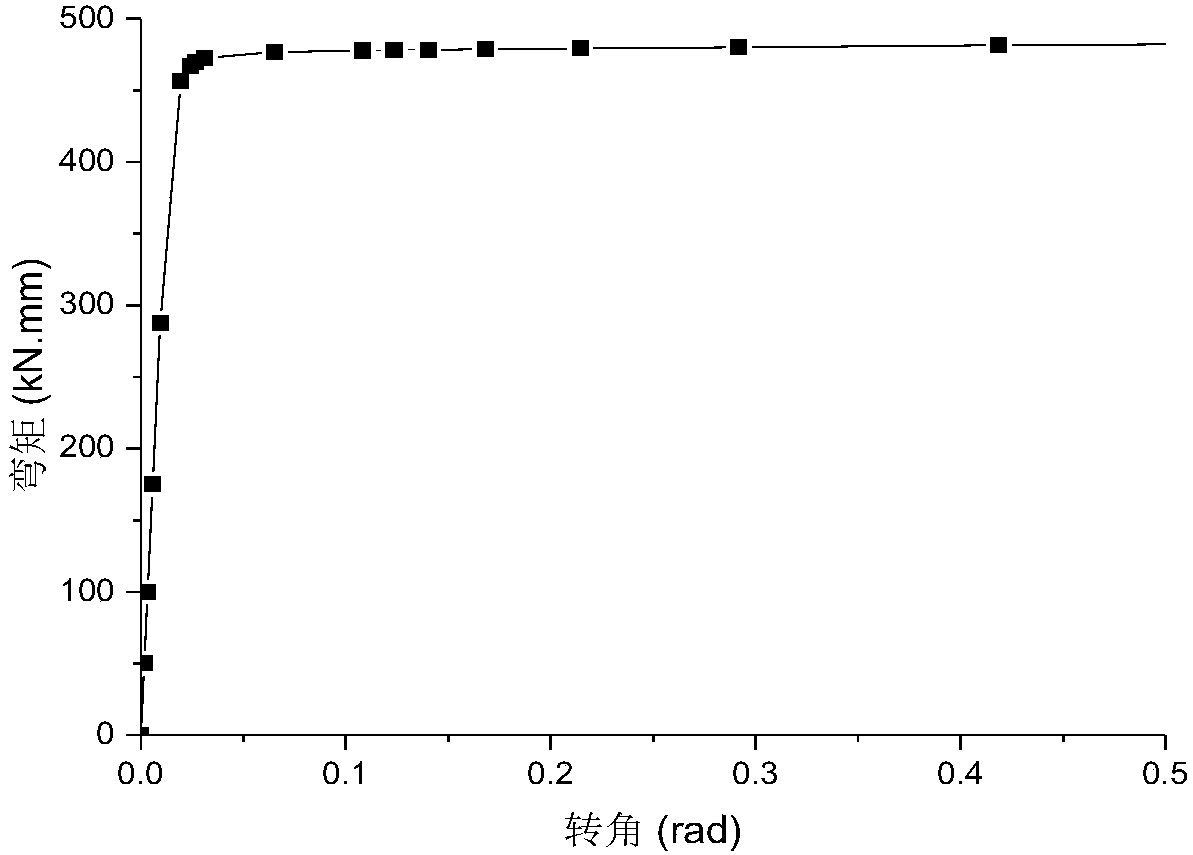

[0067] Step S3: Deduce the plastic limit bending moment formula of the pipeline with corrosion defects, and calculate the plastic limit bending moment of the tested pipeline according to...

Embodiment 2

[0091] Calculation method of embodiment 2 plastic limit bending moment

[0092] An embodiment of the present invention provides a calculation method for the plastic limit bending moment of a submarine pipeline, specifically:

[0093] Step S1: Determine the position of the plastic neutral axis according to the location and corrosion size of the corrosion defect of the pipeline under test, and calculate the tensile zone area A of the pipeline under test according to formula (1) and formula (2) I and the compression zone area A Π :

[0094] A Ι = 2R m tβ (1)

[0095] A Π = 2R m t(π-β)-2Rhθ (2)

[0096] in: is the average radius; R is the radius of the outer wall of the pipeline; t is the thickness of the tested pipeline, t is much smaller than R; h is the corrosion depth, θ is the half angle of the corrosion width;

[0097] Step S2: According to the position and corrosion size of the corrosion defect of the detected pipeline, the angle β of the plastic neutral axis, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com