Lead frame and method for manufacturing rotary mode power module by using lead frame

A technology of lead frame and rotary mold, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of increasing the complexity of module automation production and prolonging the manufacturing cycle, so as to improve production efficiency and product yield, and reduce complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

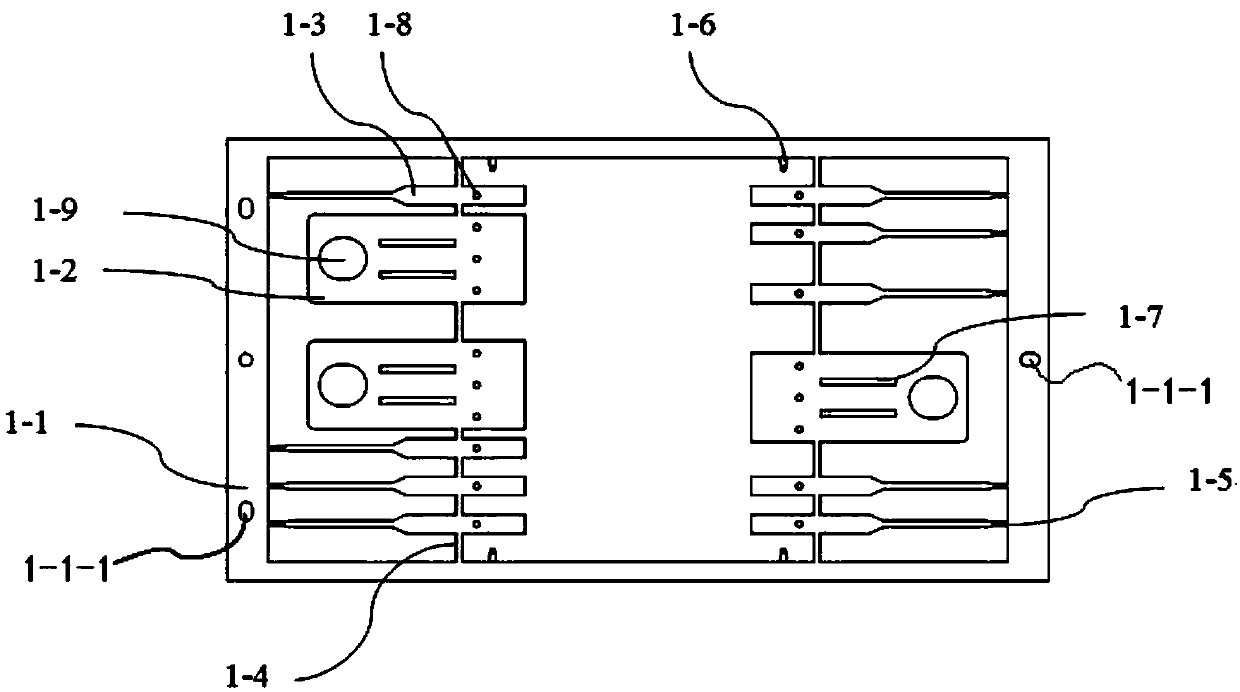

[0027] Such as figure 1 , figure 2 As shown, the present embodiment provides a lead frame 1, the lead frame 1 includes an external frame 1-1, lead-out terminals and connecting rods, the lead-out terminals are one or more, and each lead-out terminal is connected to the connecting rod through the connecting rod. Said external frame 1-1 is fixed.

[0028] Compared with the prior art, in this embodiment, each lead-out terminal is fixed relative to the external frame 1-1 through a connecting rod, so that each lead-out terminal and the external frame 1-1 form an integral body, and the specific positions of each lead-out terminal can be pre-determined according to the actual situation. Design and layout, the positioning between the ceramic liner 2 and the lead frame 1 is carried out. Through the one-time positioning of the ceramic liner 2 relative to the lead frame 1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com