Rotor component of brushless motor

A brushless motor and rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of magnetic steel displacement, turbulent use environment, unstable fixation, etc. Reduced magnetic field fluctuation, fixed and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below through specific examples.

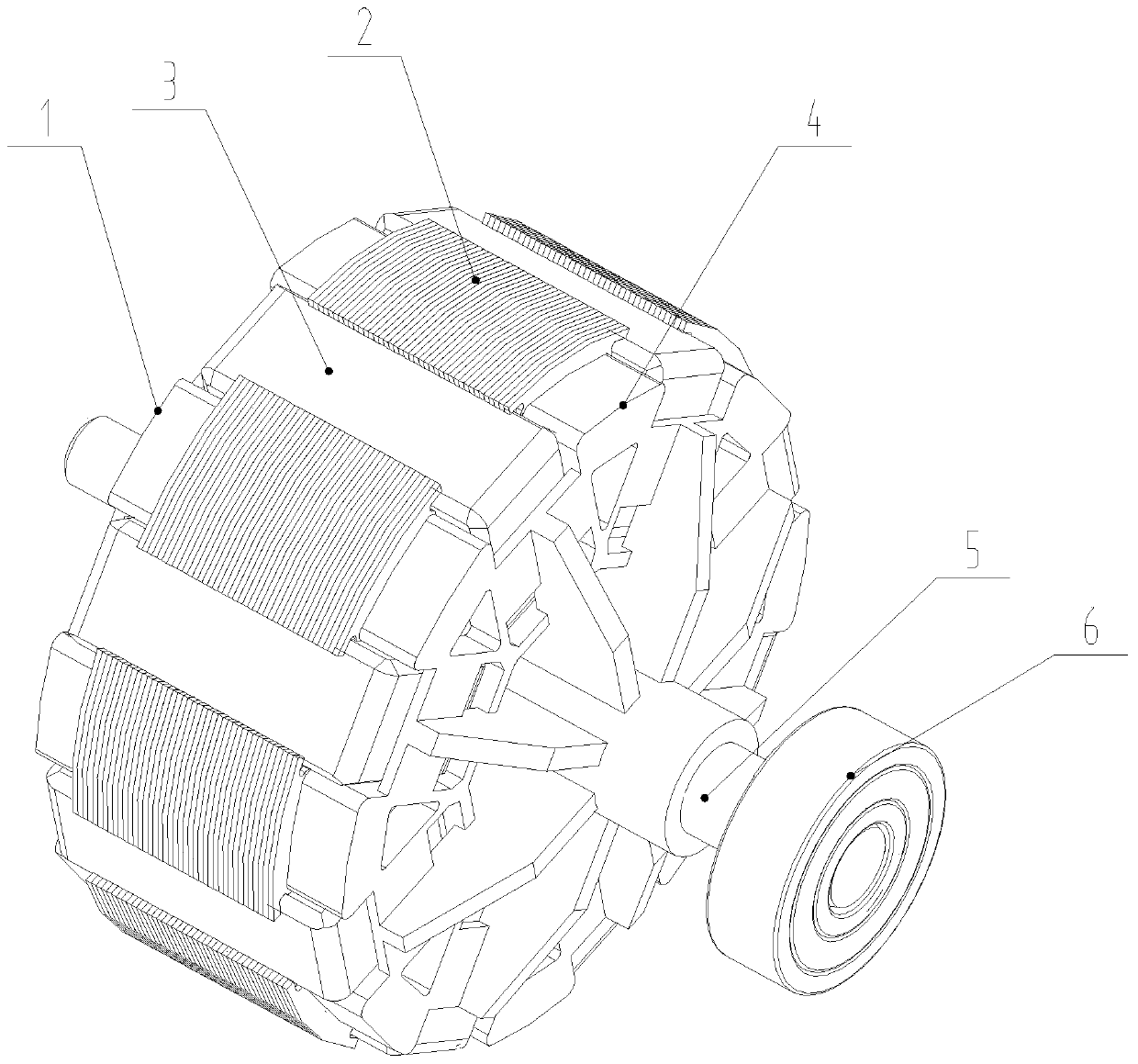

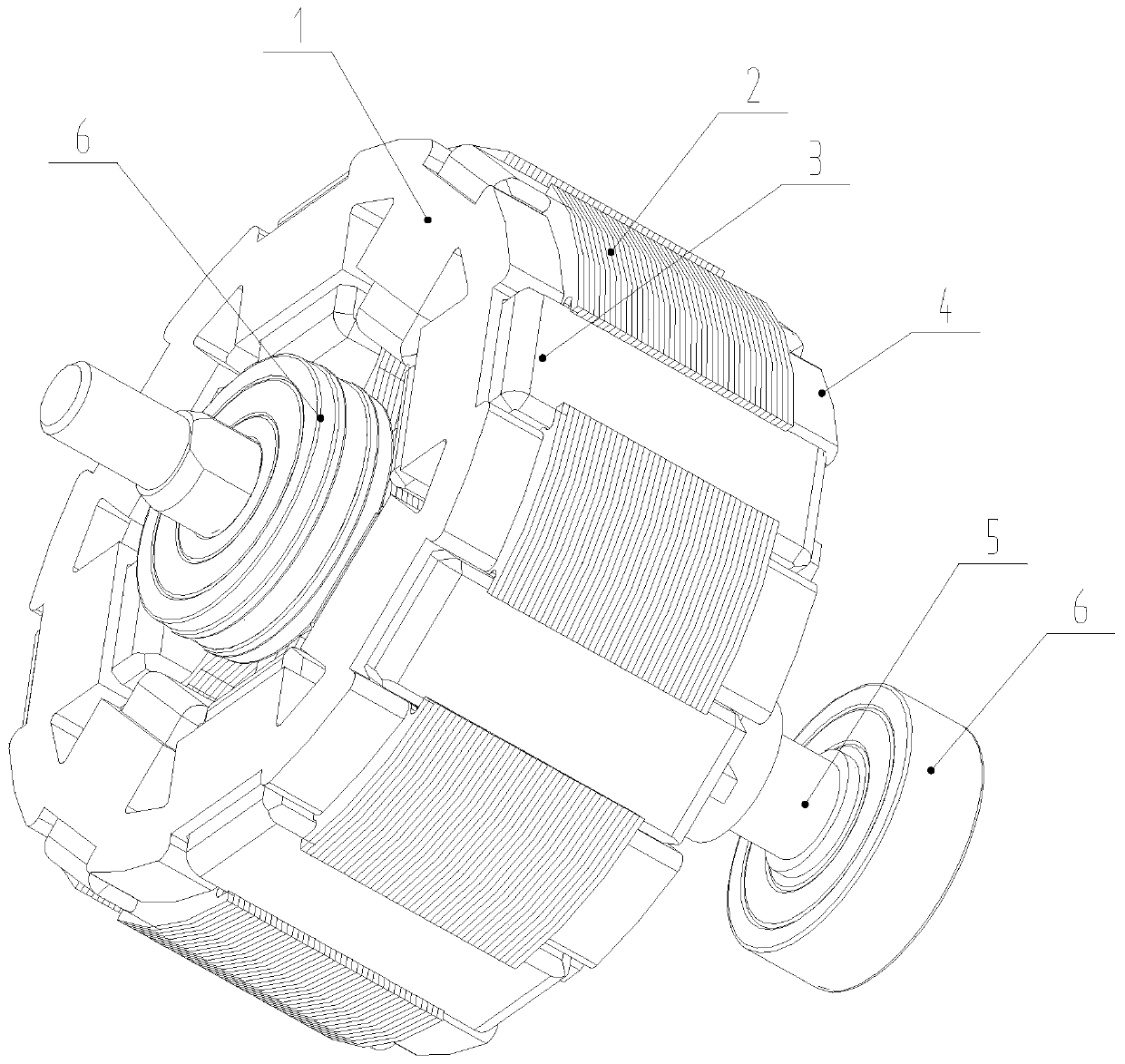

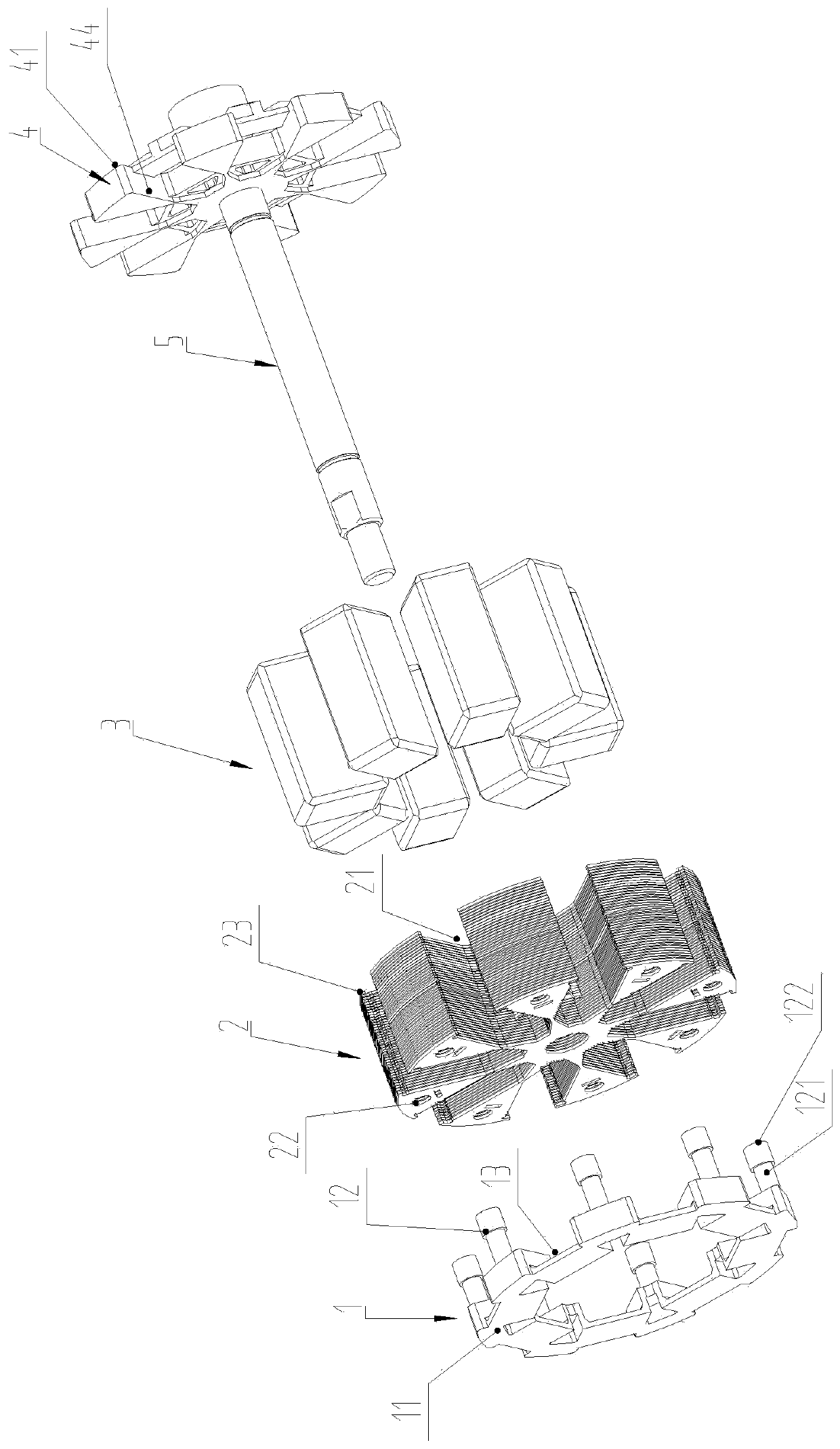

[0027] Such as Figure 1 to Figure 6 As shown, a rotor assembly of a brushless motor includes a rotor core 2, a rotor shaft 5, and a magnetic steel 3. The center of the rotor core 2 is provided with a central hole 25, and the outer circumference of the rotor core 2 is uniformly distributed. In the placement groove 21 where the magnetic steel 3 is placed, the rotor core 2 is formed by stacking silicon steel sheets of several specifications.

[0028] The rotor assembly also includes a front baffle 1 and a rear baffle 4, the rotor shaft 5 passes through the central hole 25 and the rear baffle 4 and is fixedly connected with the rear baffle, the front end and the rear end of the rotor shaft 5 are both arranged The bearing 6 is provided to facilitate the rotation of the whole rotor assembly and be installed on the casing of the motor.

[0029] The front baffle 1 is fixed on the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com