A washing machine motor rotor with mute function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

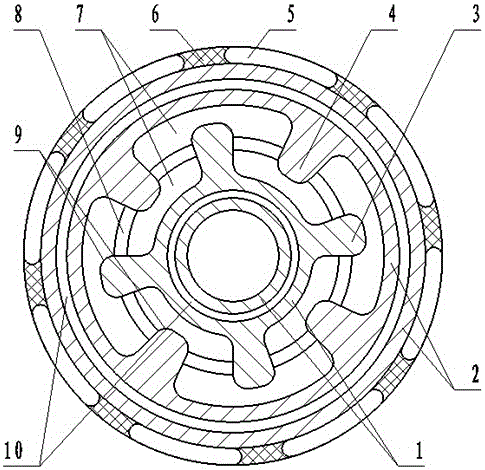

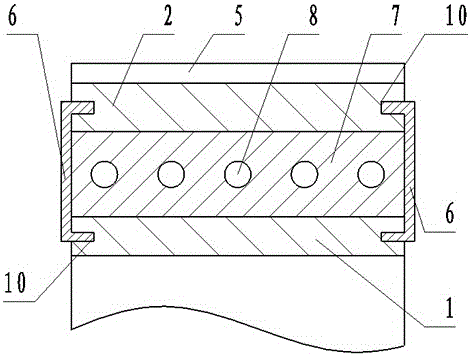

[0012] Example. A washing machine motor rotor with mute function, constituted as figure 1 , 2 As shown, the inner rotor 1 is included, and the outer rotor 2 is arranged on the outer side of the inner rotor 1; the outer surface of the inner rotor 1 is provided with a number of radially outward convex parts 3, and the inner surface of the outer rotor 2 is provided with a number of radial Inward convex part 4, there is a certain space between the adjacent external convex part 3 and the inner convex part 4; the outer surface of the outer rotor 2 is connected with evenly distributed permanent magnets 5, between two adjacent permanent magnets 5 A PBT connection seat 6 is provided; a ring-shaped rubber shock-absorbing layer 7 is arranged between the inner rotor 1 and the outer rotor 2, and a number of so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com