Laminated capacitor motor

A technology of stacked capacitors and motors, applied in the direction of induction generators, etc., can solve the problems of small dielectric constant, difficult production, inability to provide excessive torque, etc., and achieve the effect of preventing eddy current heat loss and reducing usage restrictions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

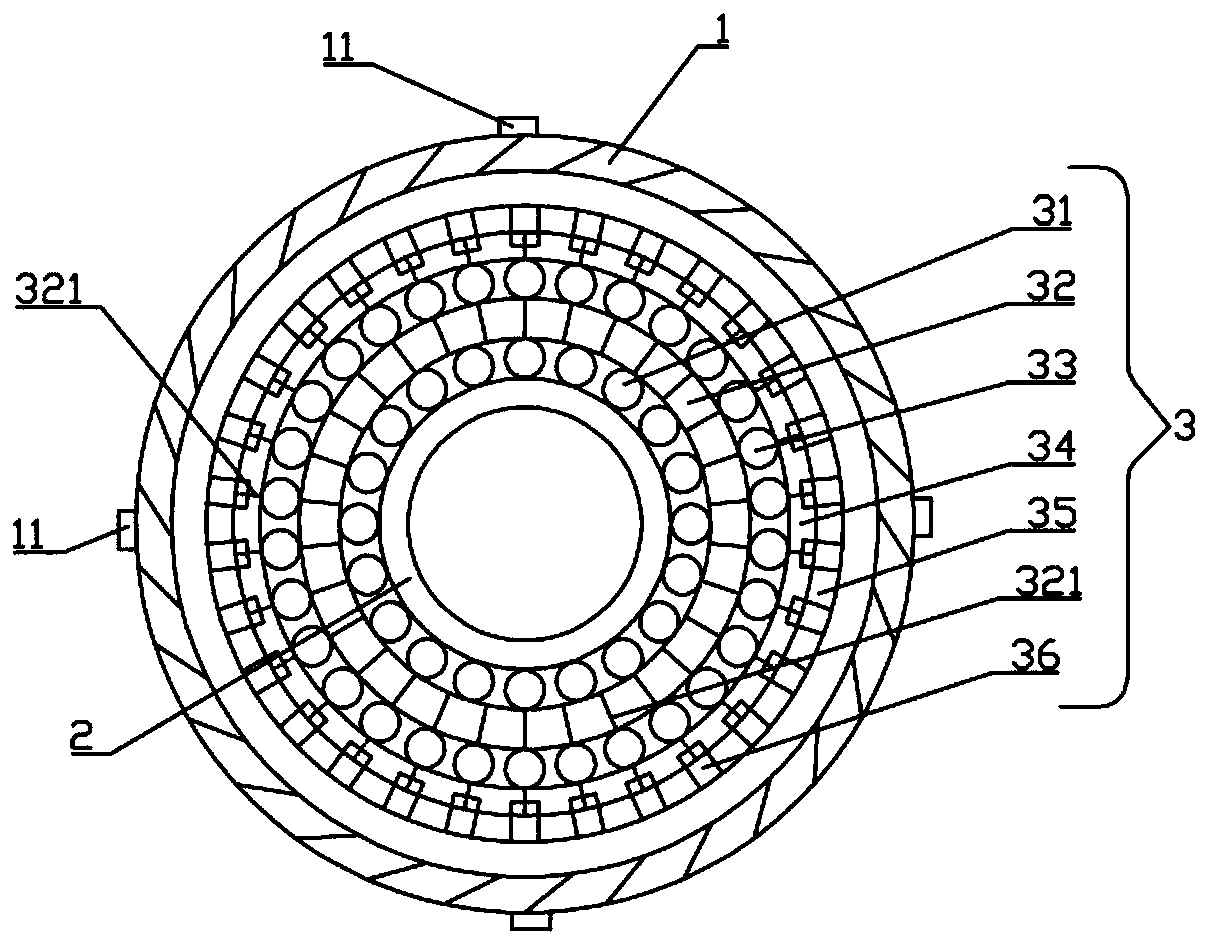

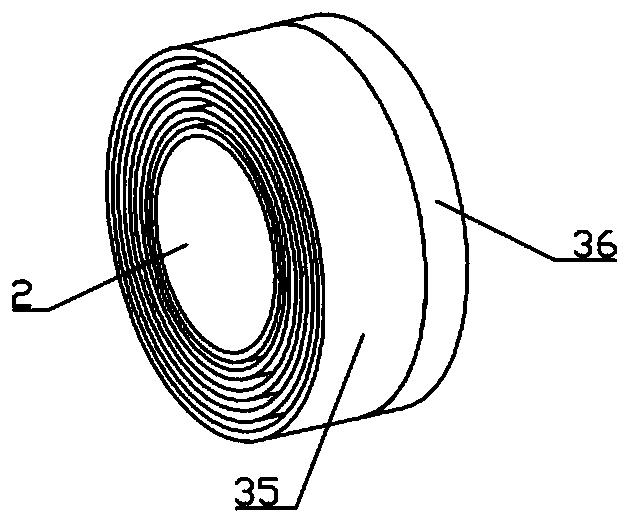

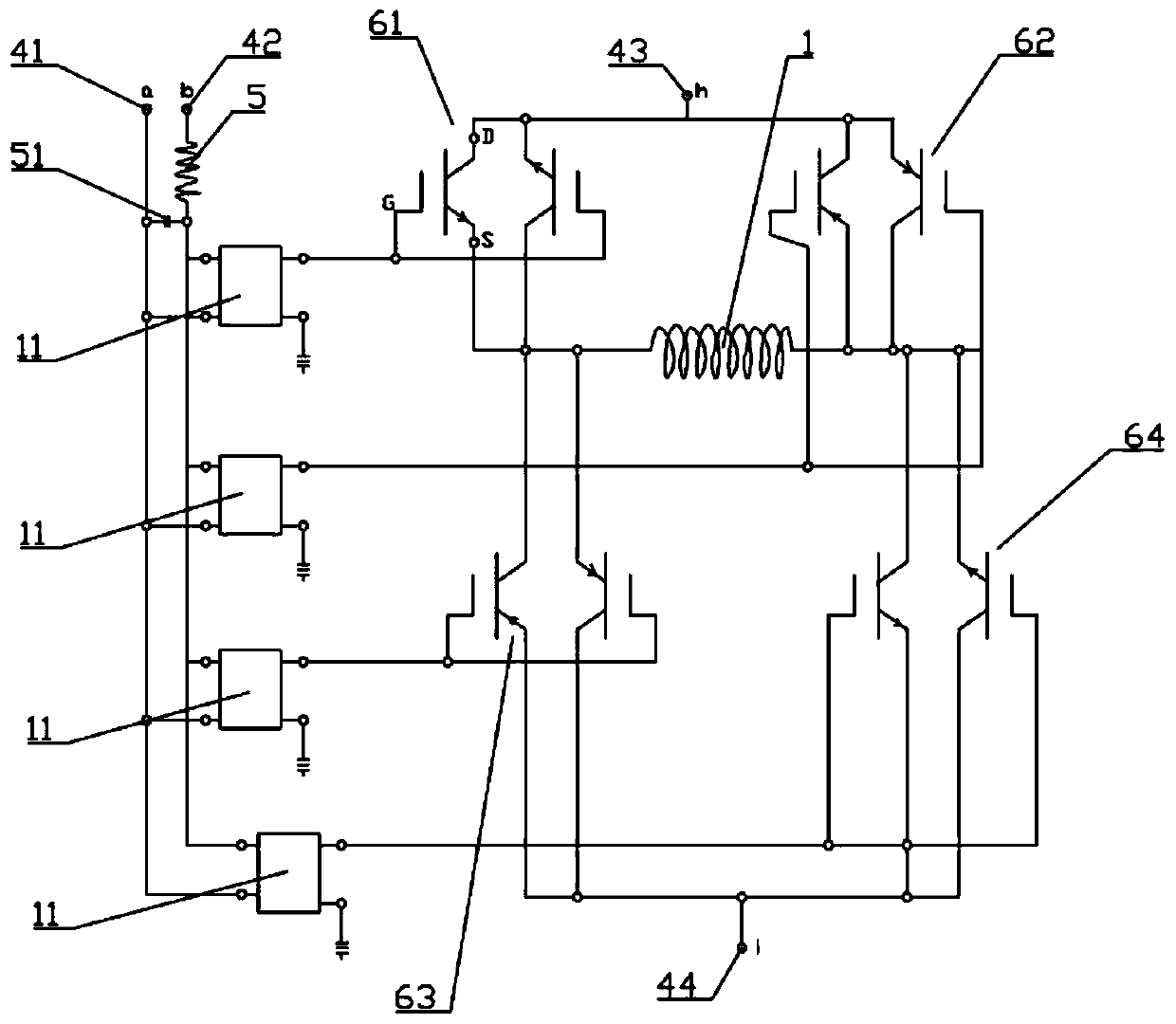

[0024] Such as Figure 1-7 As shown, a laminated capacitor motor includes a coil 1, a first rotating shaft 2 fixedly connected to the output shaft, a first connection terminal 41, a second connection terminal 42, a third connection terminal 43 and a fourth connection terminal 44, and the coil 1 There are four current Hall sensors 11, and several layers of capacitive transmission components 3 are set on the outer side of the first rotating shaft 2. The capacitive transmission component 3 includes a first ball 31, a negative capacitor plate 32, a second ball 33, a positive capacitor plate 34 and The second rotating shaft 35, the first ball 31 is located on one side of the inner wall of the capacitor negative plate 32, and the surface of the first ball 31 is rough, the inside of the capacitor negative plate 32 and the capacitor positive plate 34 are evenly distributed with a first insulating resin 321, and the second ball 33 Located between the capacitor negative plate 32 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com