Fuel reduction rate output system, fuel reduction rate output method, and fuel reduction rate output program

A technology of output system and reduction rate, which is applied in the direction of control system, steam generation, lighting and heating equipment, etc., and can solve the problem that fuel reduction rate cannot be estimated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. In addition, in all the drawings for explaining an embodiment, in principle, the same code|symbol is attached|subjected to the same part, and the repeated description is abbreviate|omitted. On the other hand, parts that are described with reference numerals in a certain drawing may be described using the same reference numerals without being shown again when describing other drawings.

[0022]

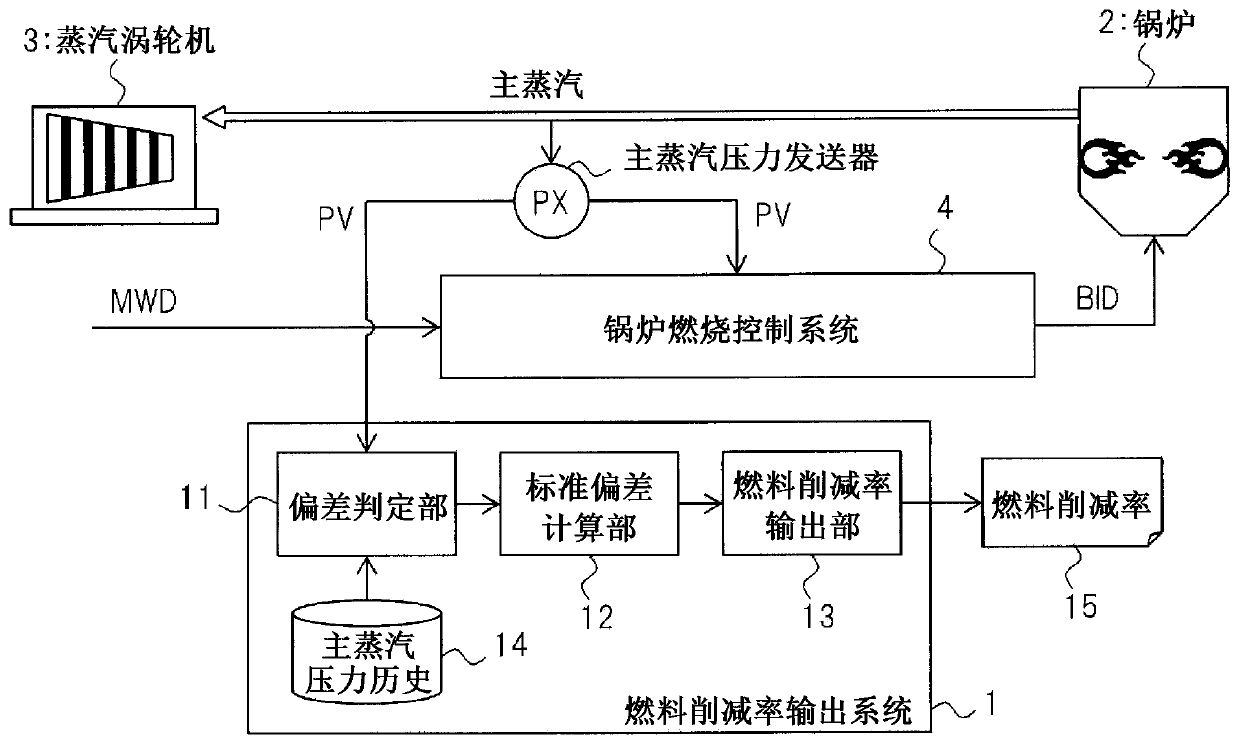

[0023] figure 1 It is a figure which shows the outline|summary of the structural example of the fuel reduction ratio output system which is one embodiment of this invention. exist figure 1 Among them, the control of the boiler 2 is carried out by the existing boiler combustion control system 4 . The boiler combustion control system 4 takes the load demand amount MWD as an input, and determines a boiler input command value BID which is a fuel input amount to the boiler by a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com