Crushing and screening integrated machine

A technology of crushing and screening, all-in-one machine, applied in the field of mining machinery, can solve the problems of manufacturing cost, operation cost and maintenance cost, high energy consumption, large area of crushing production line, wide distance installation and operation, etc., to simplify crushing Production line, improve the crushing ratio, reduce the effect of impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

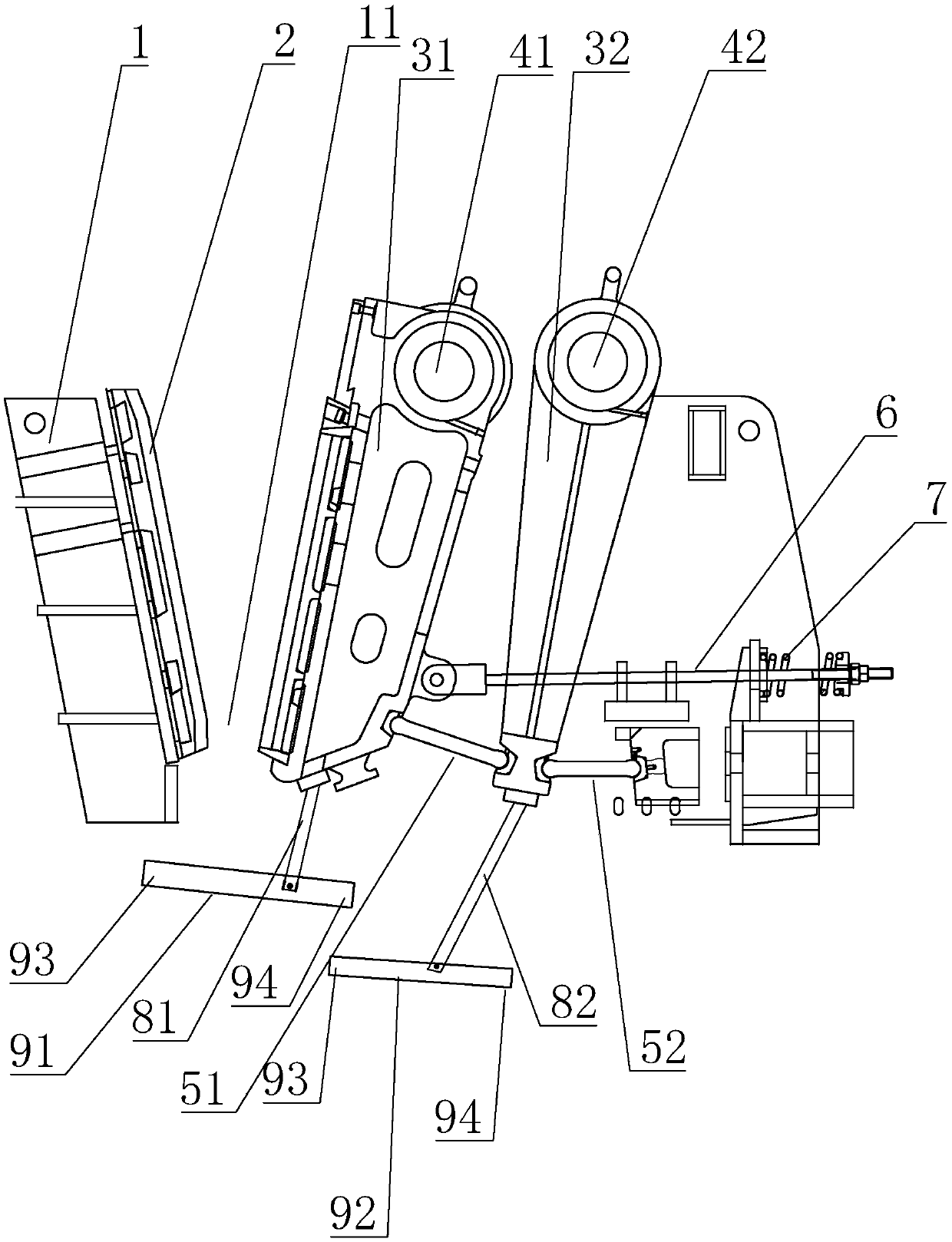

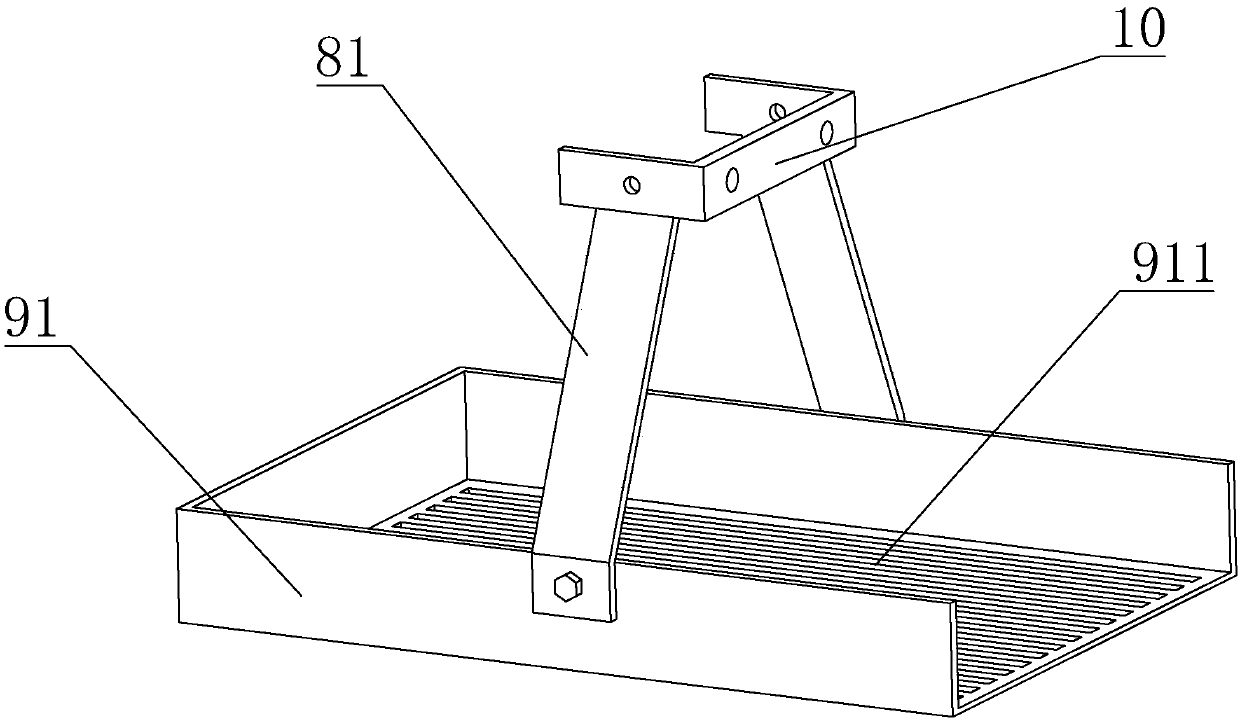

[0036] Embodiment 1: as Figure 1-3 As shown, a crushing and screening integrated machine includes a frame 1, a fixed jaw 2, a first movable jaw assembly, and a second movable jaw assembly. The fixed jaw 2 is fixedly arranged on the frame 1; the first movable jaw assembly The second movable jaw assembly includes the second movable jaw 32 and the second eccentric drive shaft 41 for driving the second movable jaw 32 Shaft 42; a first toggle plate 51 is provided between the first movable jaw 31 and the second movable jaw 32, one end of the first toggle plate 51 is pivotally connected to the lower side of the rear side of the movable jaw, and the corresponding other end is pivotally connected to the second movable jaw. The lower side of the front side of the jaw 32; a second toggle plate 52 is arranged between the second movable jaw 32 and the frame 1, one end of the second toggle plate 52 is pivotally connected to the lower side of the second movable jaw 32, and the other end is ...

Embodiment 2

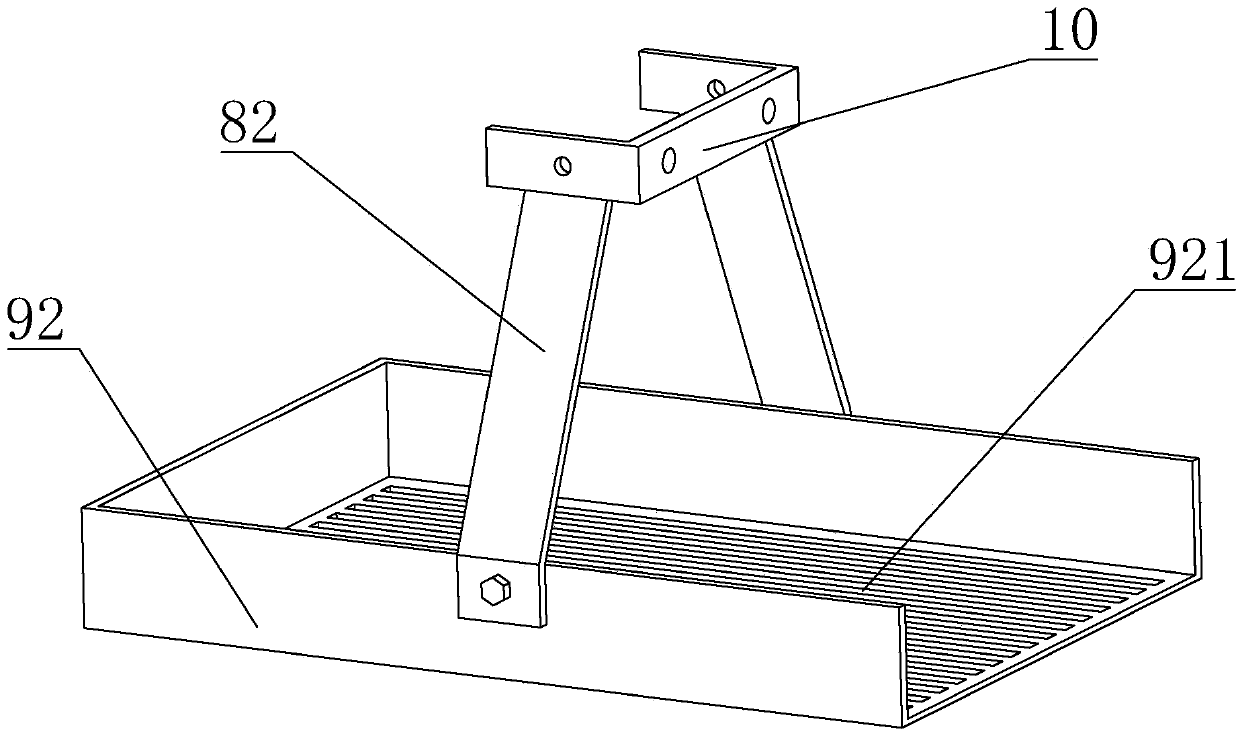

[0039] Embodiment 2: as figure 1 , Figure 4 As shown, the difference between embodiment 2 and embodiment 1 is that two layers of sieve plates are arranged in the second sieve frame 92, the upper sieve plate 923 is a sieve bar structure, the lower sieve plate 924 is a screen mesh structure, and the upper sieve plate 923 The sieving gap is larger than that of the lower sieve plate 924, and the ore sieved by the first sieve frame 91 falls from the discharge end 94 to the feed end 93 of the second sieve frame 92, and passes through the upper sieve plate 923 first. Mineral material whose particle size is larger than the sieving gap of the upper sieve plate 923 is discharged from the corresponding outlet of the discharge end 94, and mineral material whose particle size is smaller than the sieving gap of the upper sieve plate 923 falls to the lower sieve plate 924 to continue screening Mineral materials whose particle size is larger than the screening gap of the lower sieve plate 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com