Novel swash plate type automobile air-conditioning compressor

A technology for automobile air conditioners and compressors, applied in the field of compressor manufacturing, can solve the problems of large sliding frictional frictional resistance and fast swashplate wear, etc., and achieve the effects of shortened piston stroke, reduced inclination angle, and reduced frictional resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] For those skilled in the art to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments:

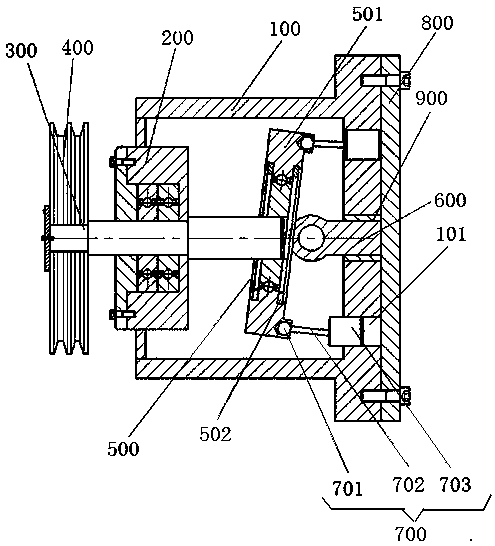

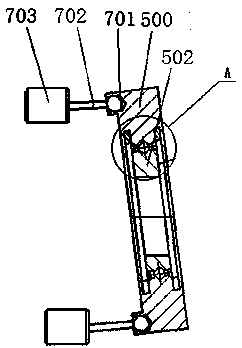

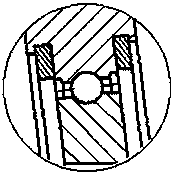

[0019] like Figure 1-4 As shown, a novel swash plate type automobile air conditioner compressor includes a compressor cylinder block 100 and a top cover 800, and the top cover 800 and the compression cylinder block 100 are connected by bolts. The bottom end of the compressor cylinder block 100 is connected to the compressor main shaft 300 through the bearing seat 200 . One end of the compressor main shaft 300 is located outside the compressor cylinder block 100 and is connected to the pulley 400, and the other end of the compressor main shaft 300 extends into the compressor cylinder block 100 and is connected to the integral swash plate 500, which includes a pressure plate 501 and the inclined bearing 502 installed in the pressure plate 501. The pressure plate 501 is evenly distributed with placement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com