Wide-load biomass cyclone burner suitable for biomass coupling coal-fired boiler

A swirl burner and coal-fired boiler technology, which is applied to burners, burners, combustion methods and other directions of burning powder fuel, can solve the problem of inability to adapt to wide loads to adjust the amount of biomass blending, poor adaptability to biomass fuel types, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

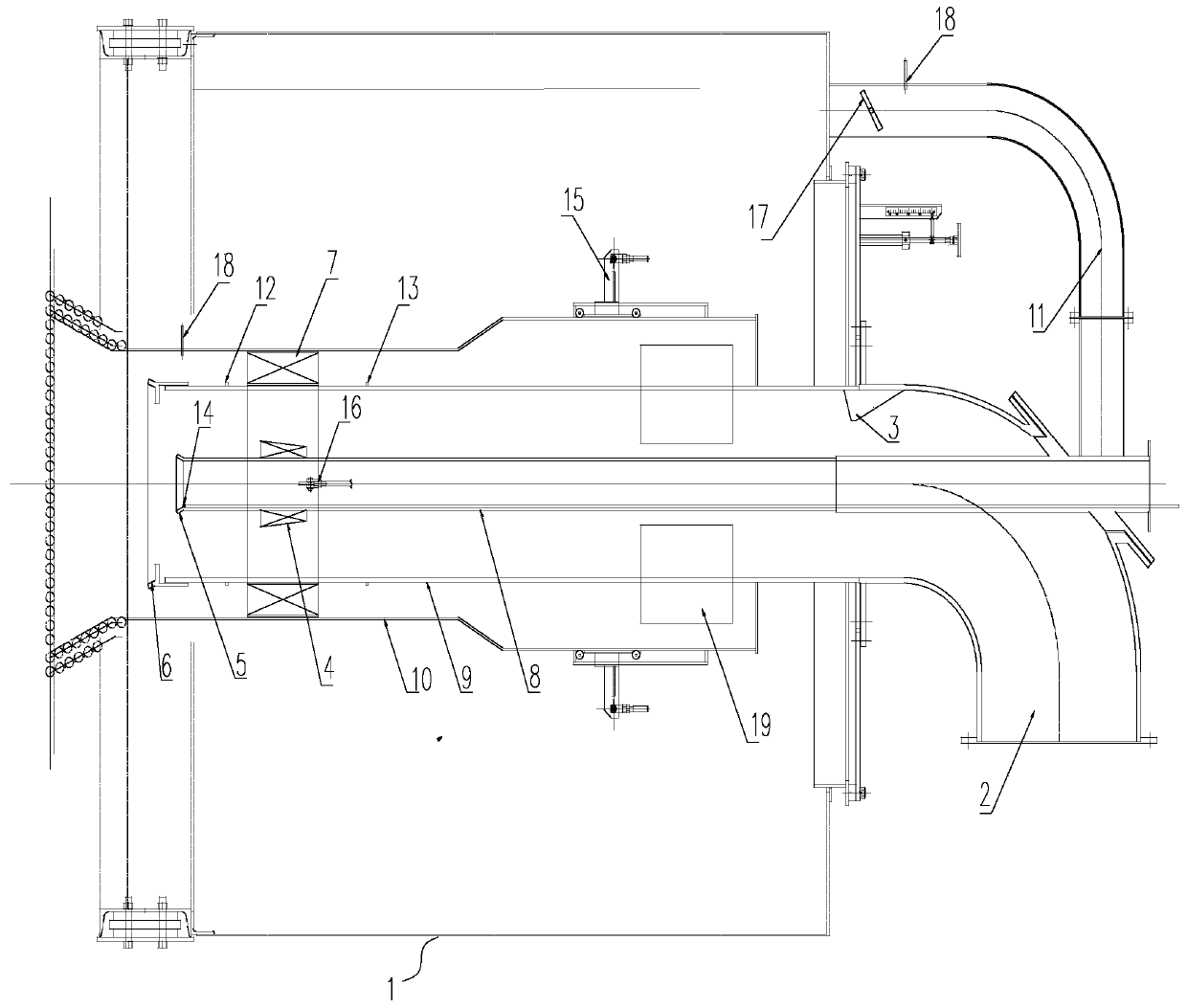

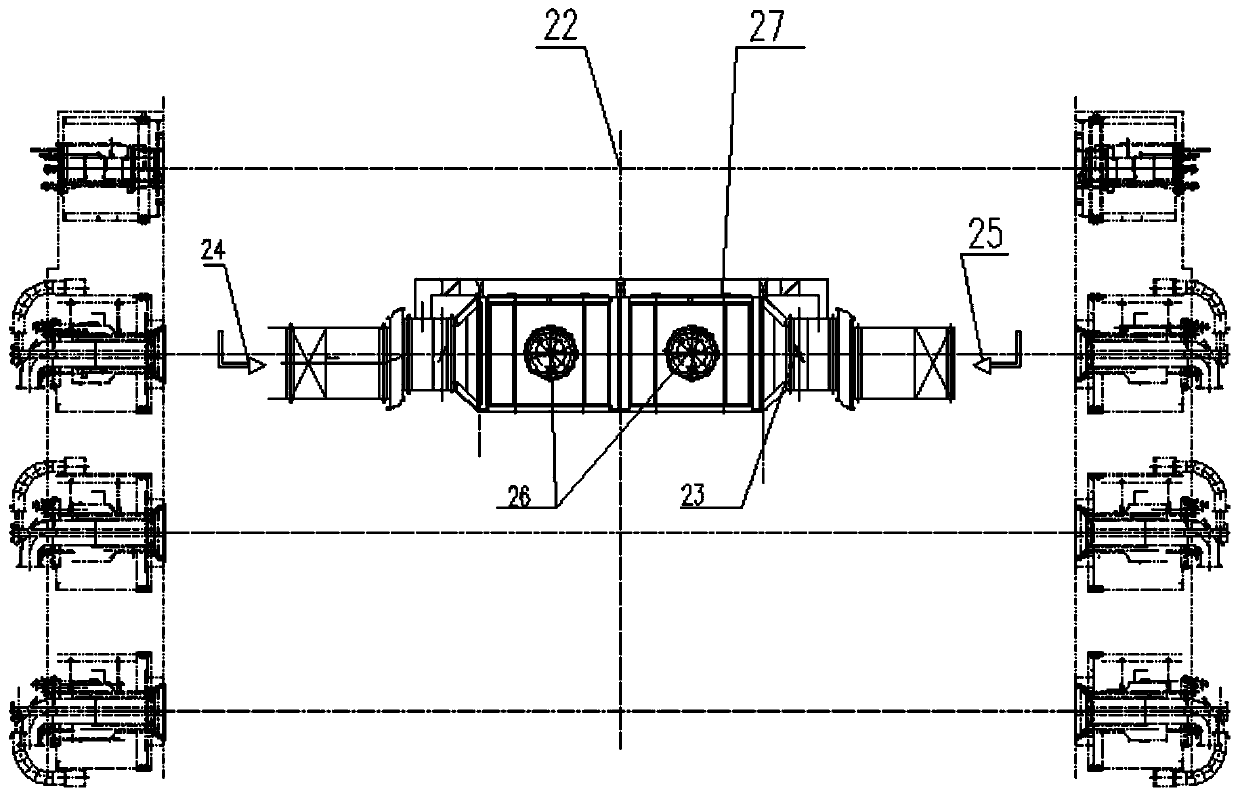

[0019] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the wide-load biomass swirl burner suitable for biomass coupled coal-fired boilers described in this embodiment includes a burner body 1, a swirl concentrator 4, a swirler 7, a central air cylinder 8, a primary The air duct 9, the secondary air duct 10 and the central air introduction pipe 11, the central air duct 8 is horizontally installed in the burner main body 1, the primary air duct 9 is set on the central air duct 8, and the secondary air duct 10 is set on the primary air duct On the cylinder 9, the swirl concentrator 4 is installed on the outer wall of one end of the central air cylinder 8, the other end of the central air cylinder 8 is connected with the central air inlet pipe 11, and the cyclone 7 is installed on the outer wall of the primary air cylinder 9 and the secondary Between the inner walls of the air duct 10.

specific Embodiment approach 2

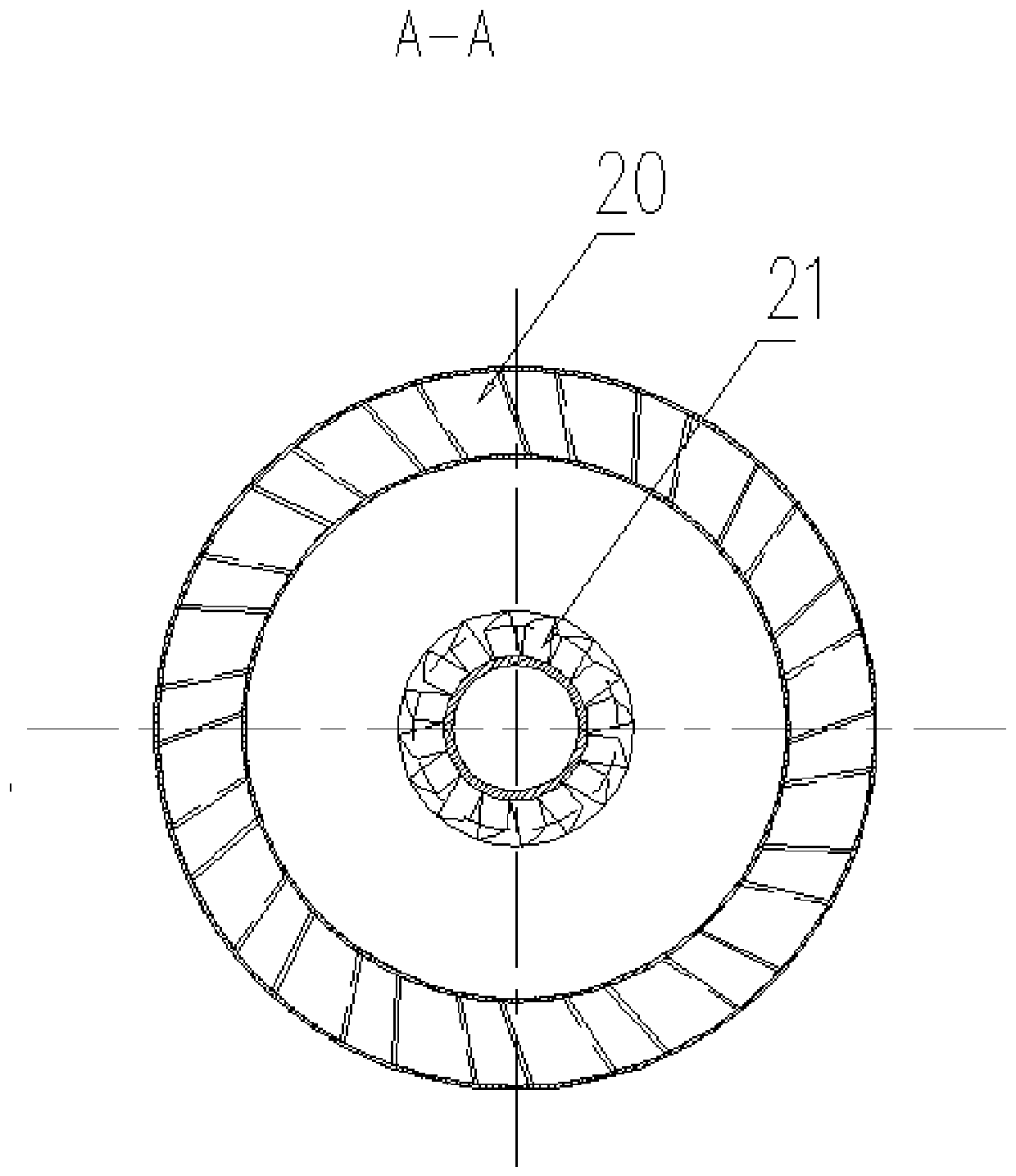

[0020] Specific implementation mode two: combination figure 2 Describe this embodiment, the swirl concentrator 4 described in this embodiment is provided with a plurality of swirl concentration blades 21, and a plurality of swirl concentration blades 21 are evenly distributed along the circumference of the swirl concentrator 4; the cyclone 7 is set There are a plurality of swirl blades 20 , and the plurality of swirl blades 20 are evenly distributed along the circumference of the swirler 7 . After the biomass powder is graded and concentrated by the rotating concentrating blade 21, it has better ignition ability. The number and relative position of the secondary wind swirl blades 20 are consistent with the swirl concentration blades 21 .

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the wide-load biomass swirl burner for biomass-coupled coal-fired boilers described in this embodiment also includes a biomass powder inlet elbow 2, and the biomass powder inlet elbow 2 is installed in the primary air duct 9 of the entrance. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com