Warehouse management system and method

A warehouse management system and warehouse management technology, applied in general control systems, control/regulation systems, data processing applications, etc., can solve problems such as low efficiency, high cost, and high risk of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

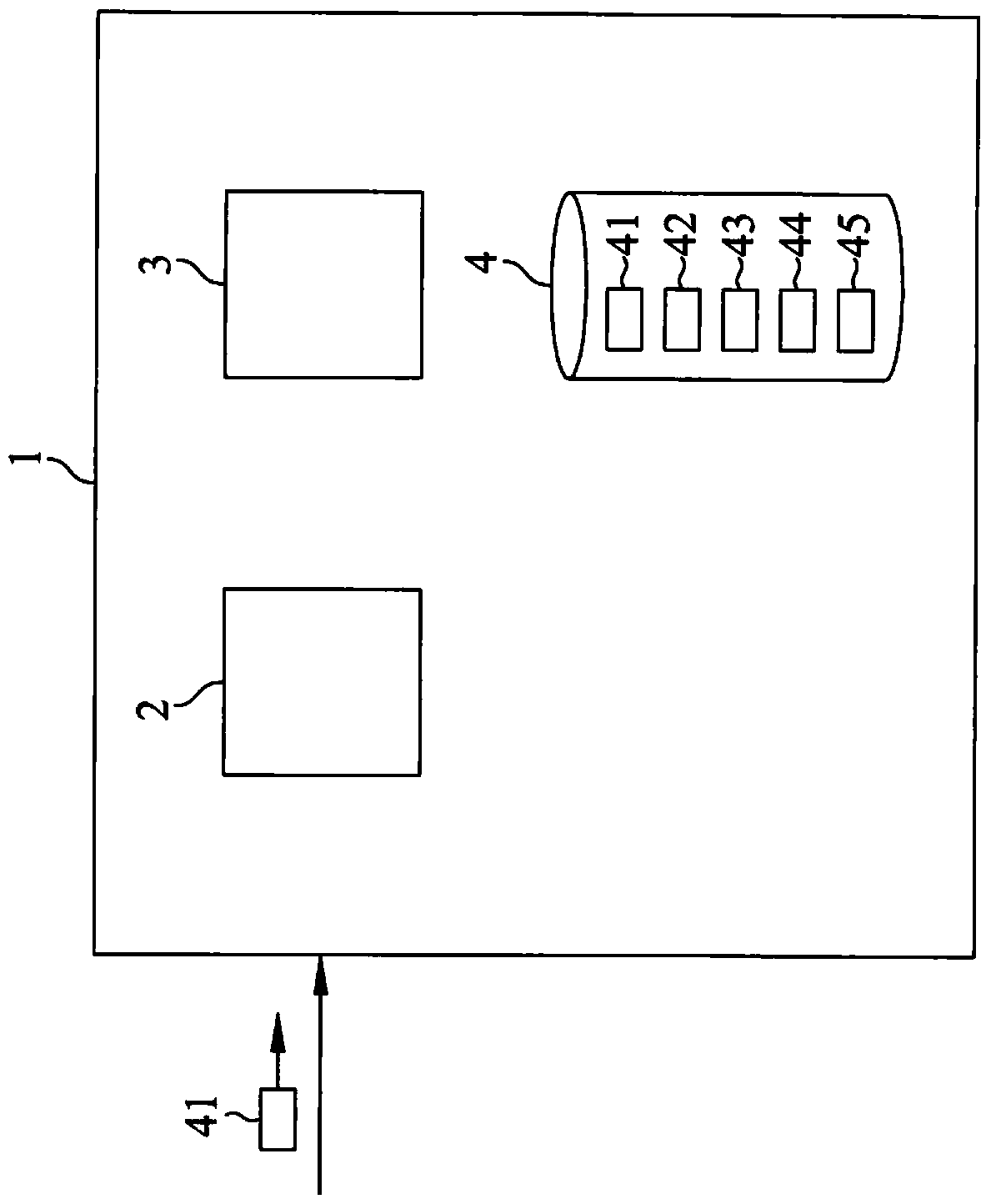

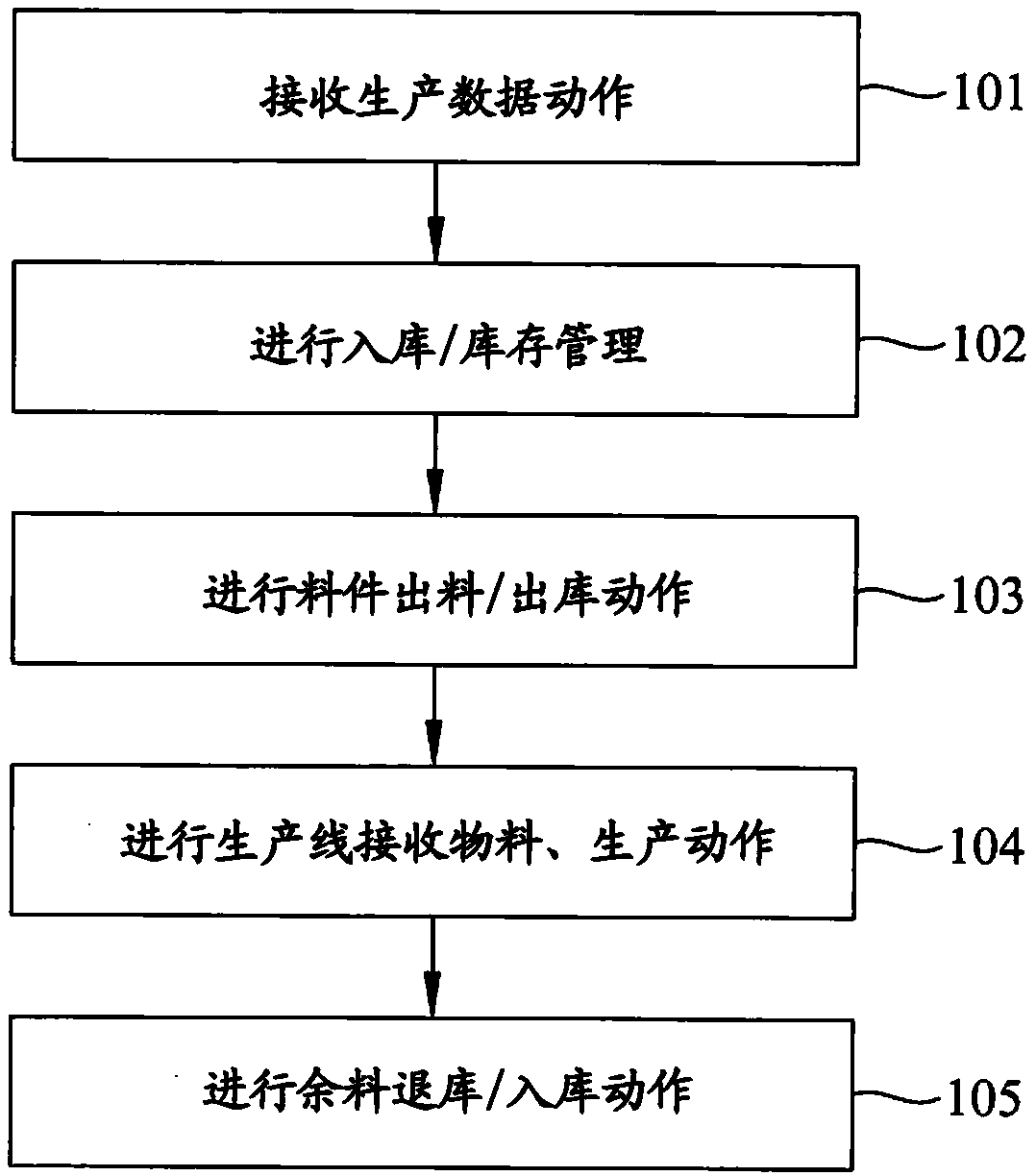

[0050] figure 1 It is a schematic diagram of the system, which is used to illustrate the system architecture and operation of the warehouse management system of the present invention. Such as figure 1 As shown in , the warehouse management system 1 at least includes a processing module 2 , a control module 3 and a database 4 .

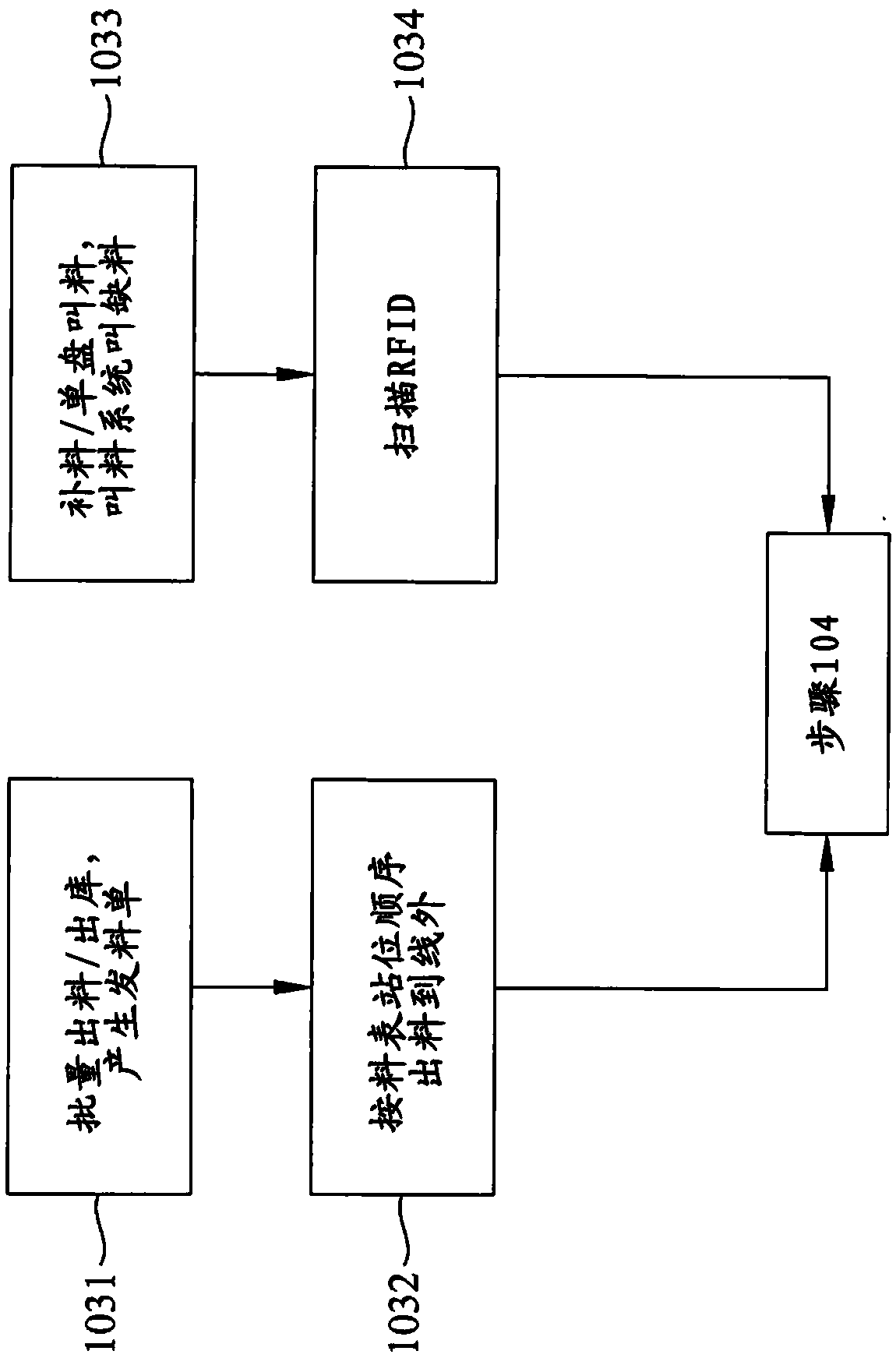

[0051]Processing module 2, the processing module 2 will perform the action of receiving production data 41, receiving material data from the ERP system and / or receiving work order data from the MES system; here, the processing module 2 can be connected with the ERP system to capture Get the BOM data of the material in the ERP system, and if the customer work order is opened in the ERP system, then connect to the ERP system to capture the work order / bill data; and / or, the processing module 2 can be connected with the MES system Docking, and if the customer work order data is in the MES system, link the MES system to capture the MES work order / material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com