Picking device, picking system and picking method for shell-shaped dental appliance

A technology of orthodontic appliances and picking devices, which is applied in the field of orthodontics, can solve problems such as inability to meet shell-shaped orthodontic appliances and low production efficiency, and achieve the effects of saving manpower, improving picking efficiency, and avoiding missed picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

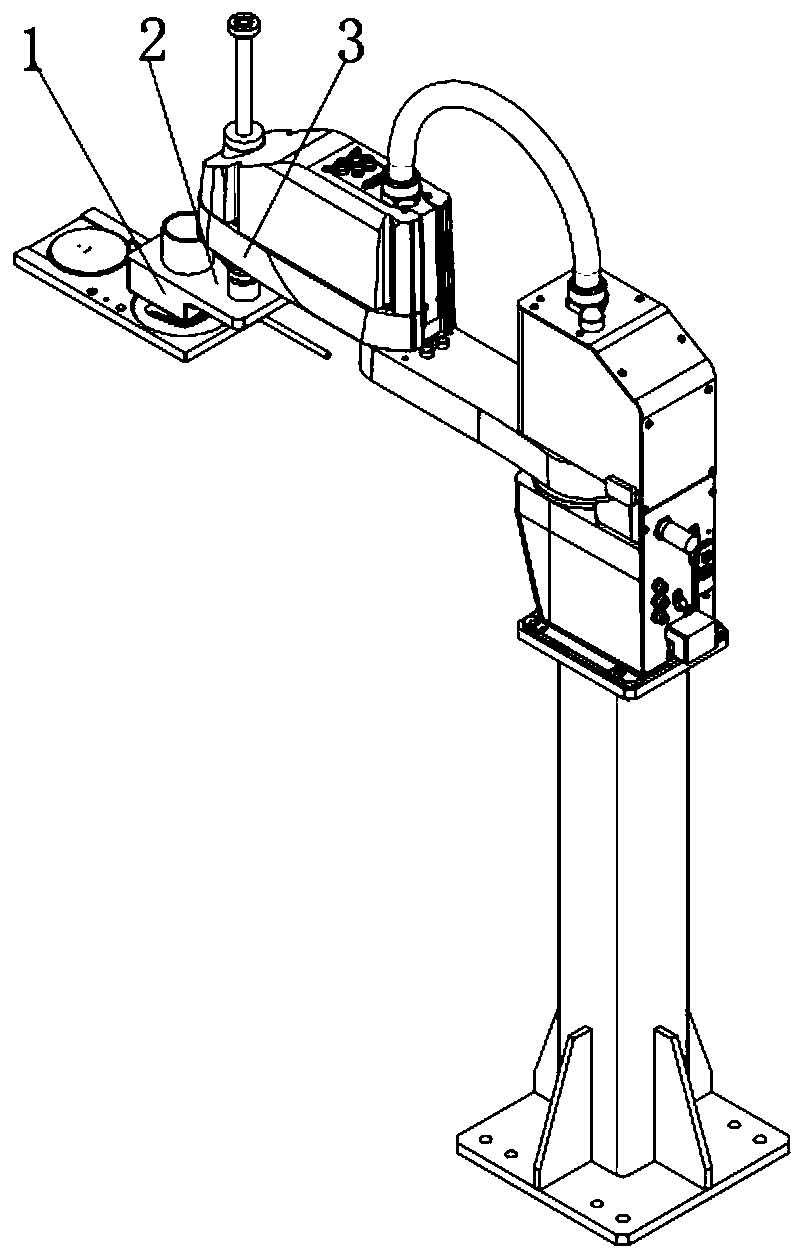

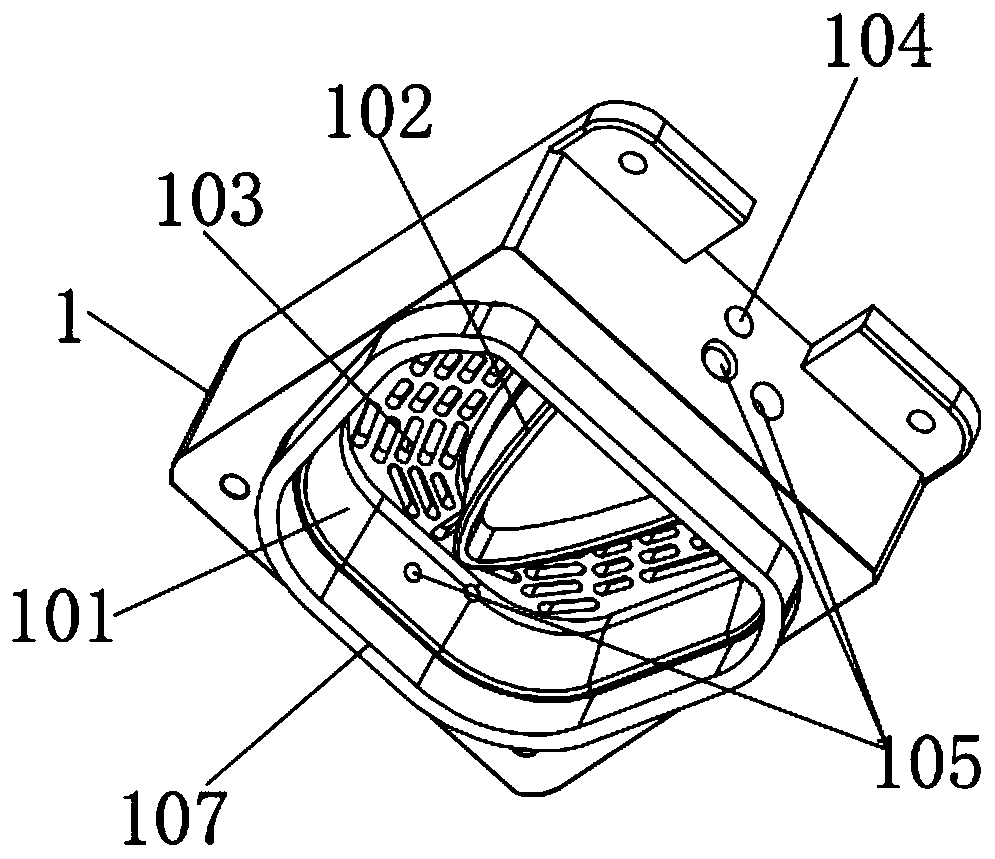

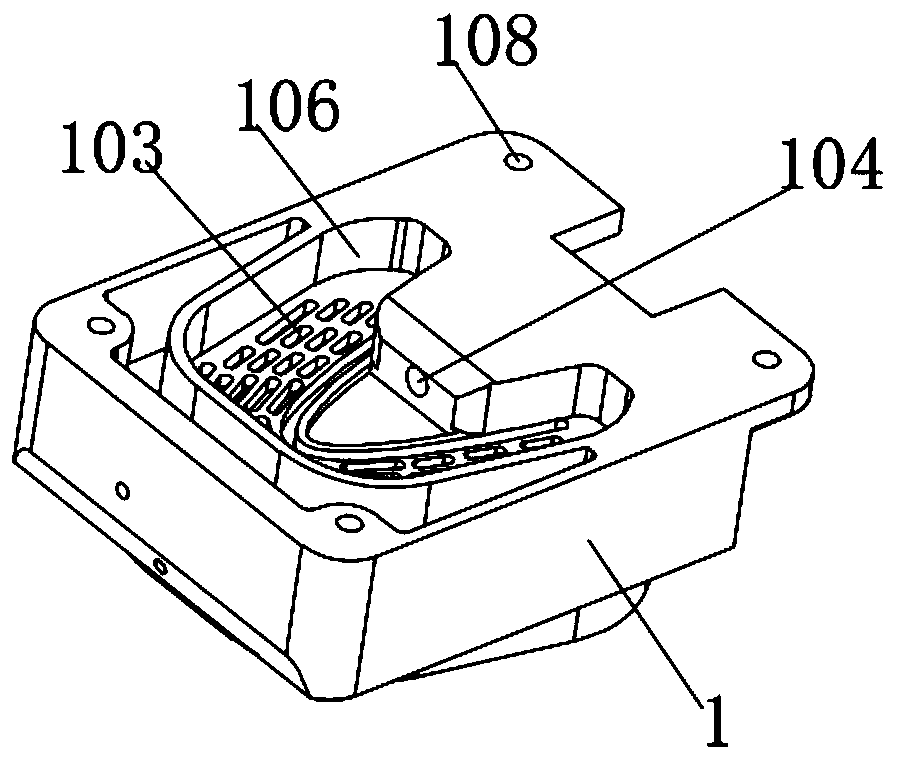

[0034] refer to Figure 1-3 , this embodiment provides a pick-up device for a shell-shaped dental appliance, including: a pick-up component 1, a negative pressure generating component; The orthodontic appliance is picked up from an initial position to a predetermined pick-up position in the pick-up assembly 1; and a pick-up confirmation assembly arranged on the pick-up assembly 1 for detecting whether the shell-shaped orthodontic appliance has reached the pick-up position.

[0035] The picking device of the shell-shaped dental appliance provided by the present invention realizes the automatic picking of the shell-shaped dental appliance through the cooperation of the picking component 1 and the negative pressure generating component, which is beneficial to the fully automatic operation of the entire production line of the shell-shaped dental appliance. Compared with the manual picking in the prior art, the manpower is greatly saved and the picking efficiency is improved.

[0...

Embodiment 2

[0055] refer to Figure 4 , this embodiment provides a pick-up system for a shell-shaped dental appliance, including a control device 11, an actuator 3, a negative pressure generating component 14, and a pick-up component, and the control device 11 is respectively connected to the actuator 3 and the negative pressure generating component. The pick-up component is provided with a pick-up confirmation component 12 for detecting changes in negative pressure parameters and an air pressure detection component 13 for detecting changes in optical parameters. The pick-up confirmation component 12 and the air pressure detection component 13 are respectively connected to the control device in communication.

[0056] Wherein, the specific structure and mutual connection mode of actuator 3, picking up confirming component 12, air pressure detecting component 13, negative pressure generating component 14 and picking component can refer to the description in embodiment 1, and do not limit he...

Embodiment 3

[0059] refer to Figure 5 A method for picking up a shell-shaped dental appliance is shown, using the picking-up system of the shell-shaped dental appliance in Embodiment 1.

[0060] Specifically, the method for picking up the shell-shaped dental appliance includes the following steps:

[0061] The control device acquires a picking command for picking up the shell-shaped dental appliance;

[0062] The control device controls the executive mechanism to drive the picking assembly to move to the placement position of the shell-shaped dental appliance according to the picking command, and starts to pick up the shell-shaped dental appliance;

[0063] The control device further confirms whether the shell-shaped dental appliance is picked up from an initial position to a predetermined pick-up position in the pick-up component through the pick-up confirming component.

[0064]Specifically, the control device controls the actuator to drive the pick-up assembly to move to the pick-up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com