A cable processing wire guide degreasing device

A wire and cable technology, applied in the field of wire guide oil removal device and oil removal device in cable processing, can solve the problems of high labor participation, high labor cost, large production burden, etc., and achieve less labor participation and structural Compact and easy to handle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

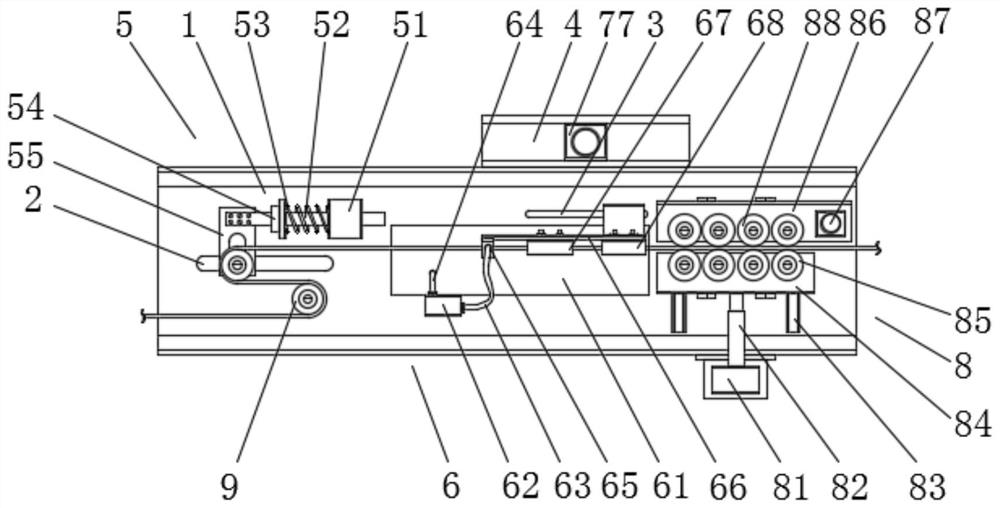

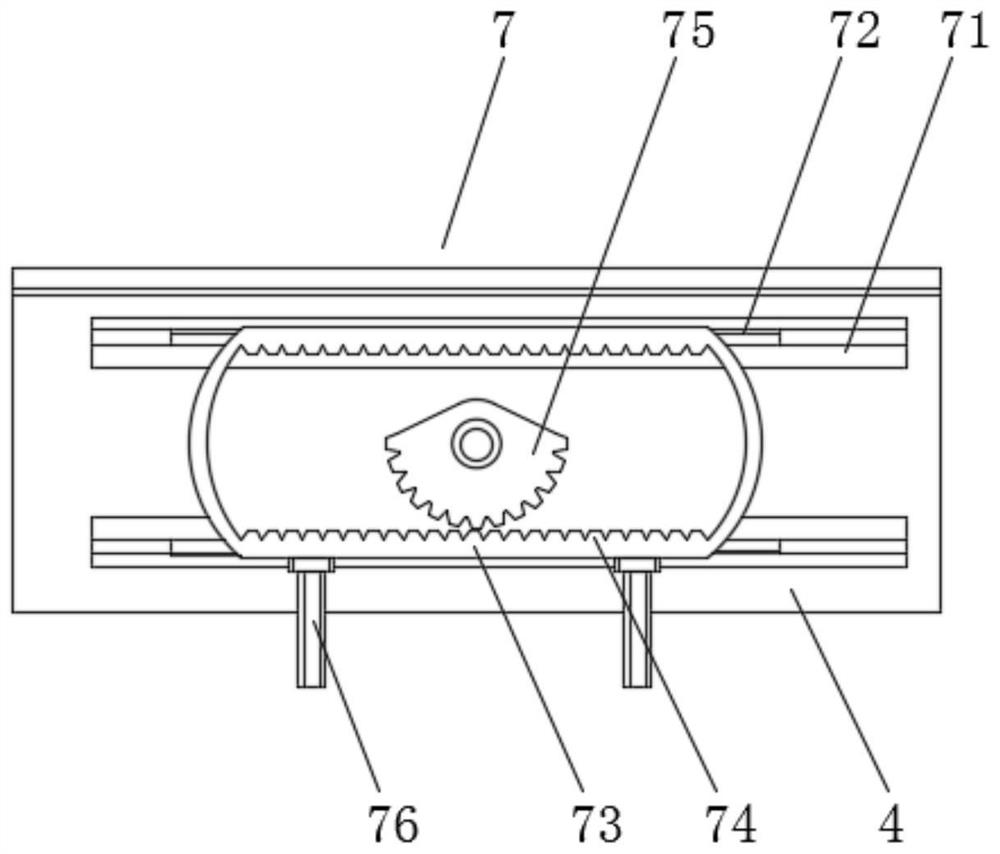

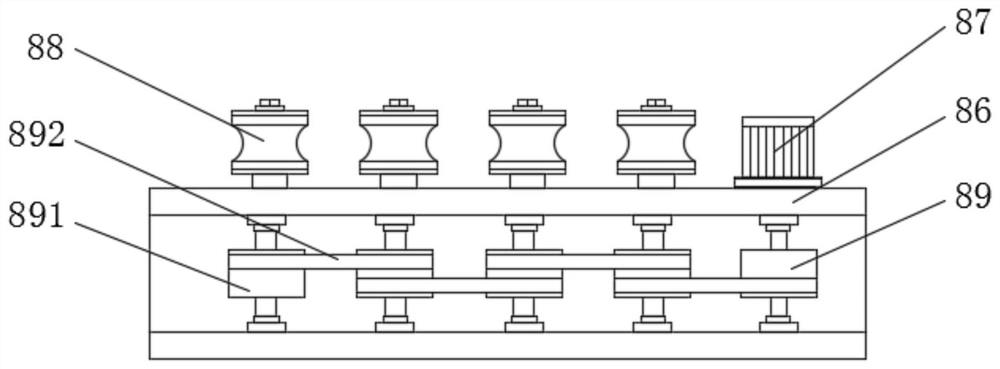

[0023] Example: such as Figure 1-6 As shown, a cable processing wire guide degreasing device of the present invention includes an operating table 1, a driving box 4, a tensioning mechanism 5, an oil removing mechanism 6, a pendulum mechanism 7 and a traction mechanism 8, and the operating table 1 There are No. 1 chute 2 and No. 2 chute 3 on the upper side, and a driving box 4 is fixed with screws on one side of the operating table 1. A pendulum mechanism 7 is provided inside the driving box 4, and a tensioning mechanism 5 is provided above the operating table 1. , Degreasing mechanism 6 and traction mechanism 8, one side of No. 1 chute 2 and fixed pulley 9 are installed on the upper side of operation table 1, and pendulum mechanism 7 includes No. 1 slide rail 71, slide block 72, and pendulum frame 73 , gear plate 74, half gear 75, No. 1 motor 77 and push rod 76, two slide blocks 72 are fixedly connected to the lower side of the swing frame 73, and two No. 1 slide rails 71 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com