Label digital die cutting machine

A die-cutting machine and digital technology, applied in the direction of metal processing, flat products, household appliances, etc., can solve the problem of inability to realize automatic feeding, film-coating die-cutting, waste discharge, slitting, rewinding processes, unsuitable for printing, Problems such as short order production and inability to automatically label, etc., to achieve high production efficiency, improve automation, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

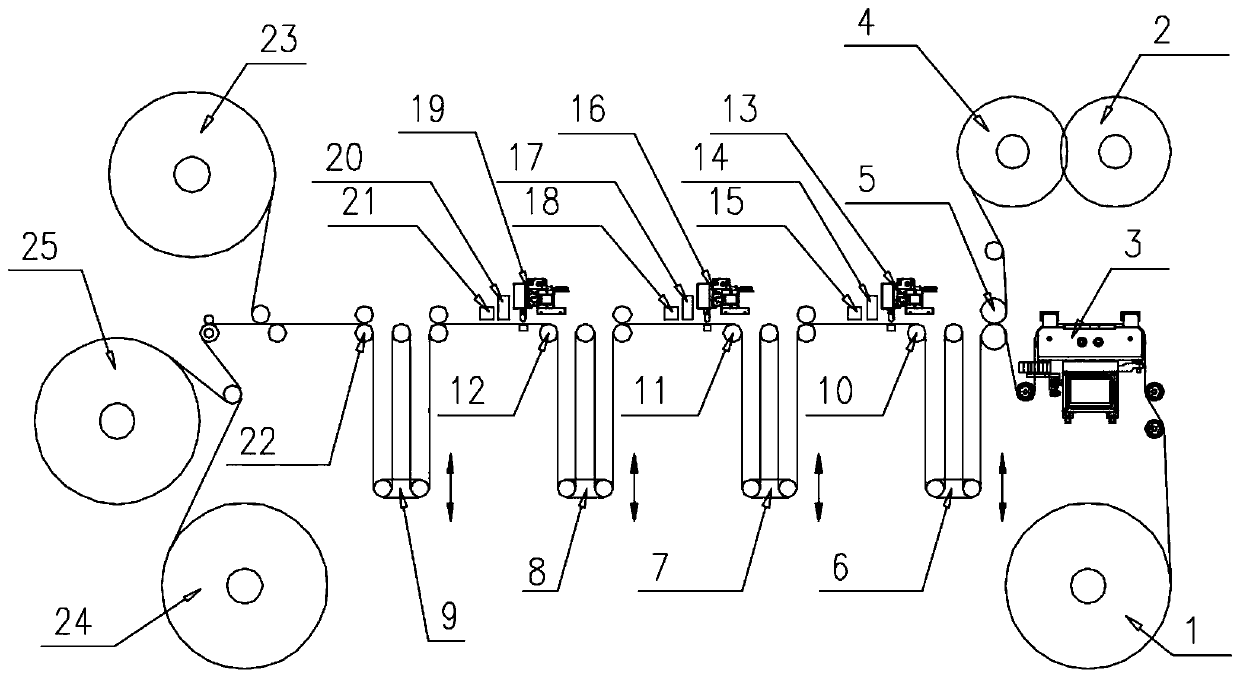

[0019] see figure 1 , in an embodiment of the present invention, a label digital die-cutting machine includes an unwinding roller 1, a film-coated bottom paper roller 2, a deviation correction device 3, a film-coated roll roller 4, a paper-feeding driving roller 5, and a paper-receiving driving roller arranged in sequence. Roller 22, waste discharge roller 23, rewinding roller lower 24 and rewinding roller upper 25, wherein, a unit one is arranged between the floating assembly one 6 and the floating assembly two 7, and the floating assembly two 7 and the floating assembly two A unit two is arranged between the floating assembly three 8, and a unit three is arranged between the floating assembly three 8 and the floating assembly four 9;

[0020] Specifically, in the embodiment of the present invention, the unit one includes a Y axis one 13, a color mark sensor one 14 and a camera one 15;

[0021] The unit two includes a Y axis two 16, a color mark sensor two 17 and a camera tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com