Electric vehicle charger with heat dissipation device

A cooling device and electric vehicle technology, applied in the direction of electric vehicle charging technology, electric vehicles, charging stations, etc., can solve problems such as explosion, affecting charging performance, and affecting the service life of chargers, and achieve lower ambient temperature and good flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

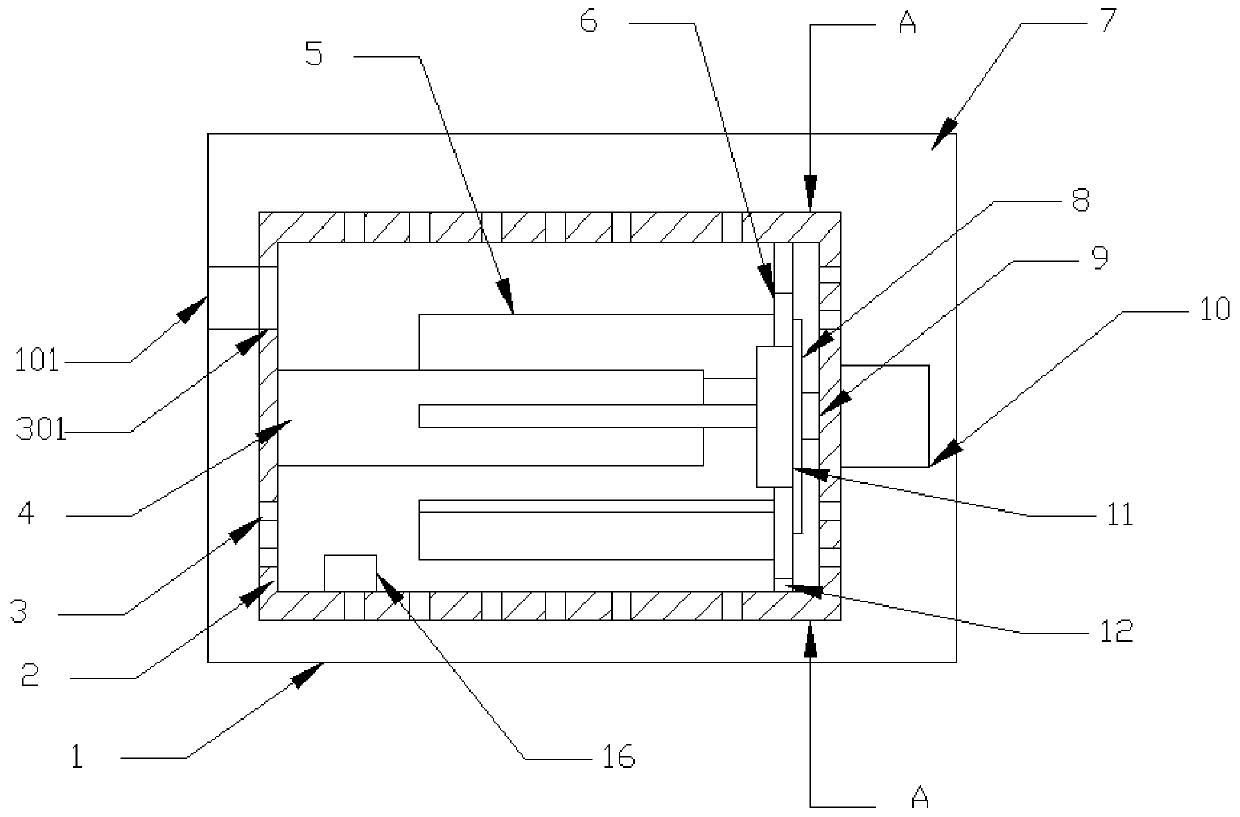

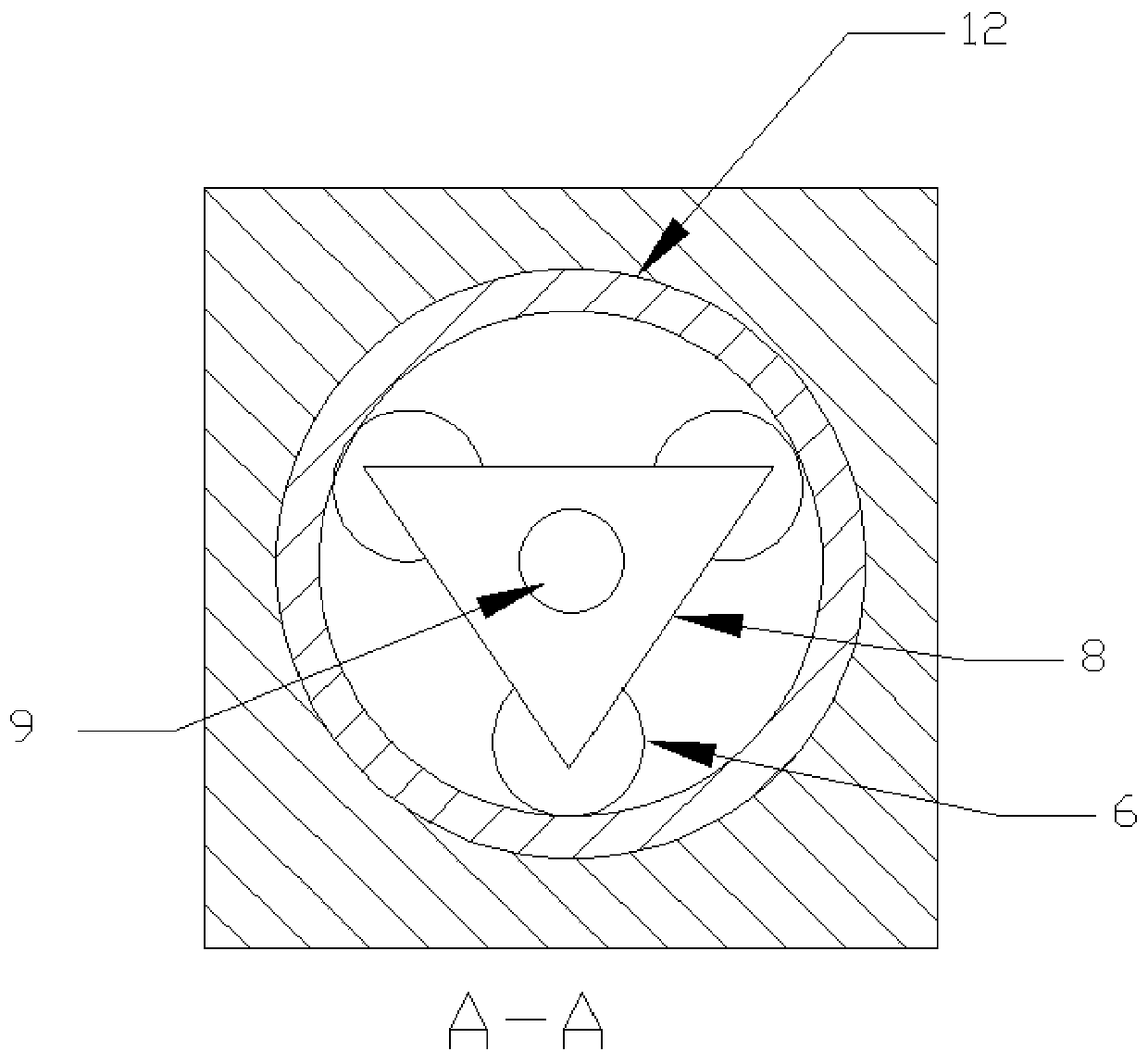

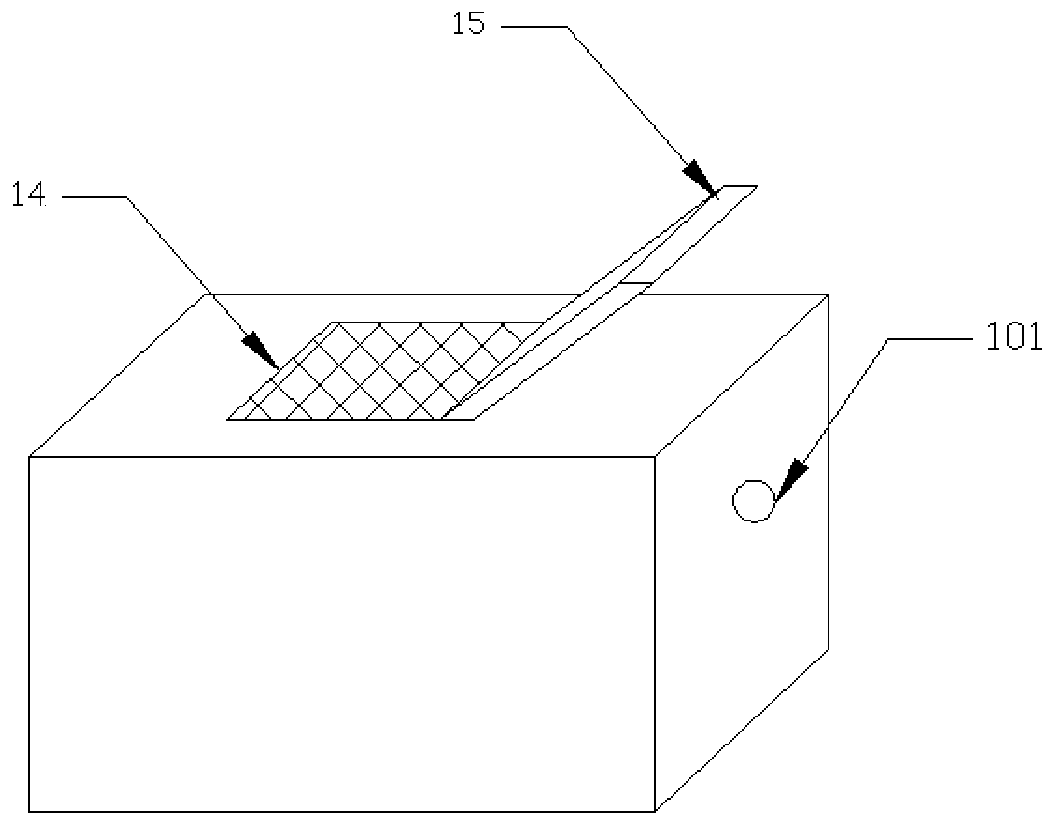

[0019] combine Figures 1 to 5 As shown, a kind of electric vehicle charger with cooling device 2 includes electric vehicle charger body 4, and electric vehicle charger also includes cooling device 2; cooling device 2 adopts cooling tank 3; electric vehicle charger body 4 is fixedly arranged on At the center position of an end face in the heat dissipation tank 3; the heat dissipation device 2 also includes a motor 10, a rotating shaft 9, a stable bracket 13, a sun gear 11, a planetary gear 6, and a ring gear 12; the ring gear 12 is internally connected in the heat dissipation tank 3, close to The other end surface of the heat dissipation tank 3; a through hole 802 is provided at the center of the triangular plate 8, and a ring-shaped protrusion 801 is provided extending from the through hole 802 into the tank; the ring-shaped protrusion 801 is covered with a sun gear 11; The sun gear 11 is internally connected with a stabilizing bracket 13; the motor 10 is fixed at the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com