Insertion-rod-type vehicle stop device for mine

A technology for mining and inserting rods, which is applied in the direction of mandatory railway stopper, transportation and packaging, railway car body parts, etc., can solve the problems of increased workload, inconvenience, accidental injury to staff, etc., and achieves convenient operation and use effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

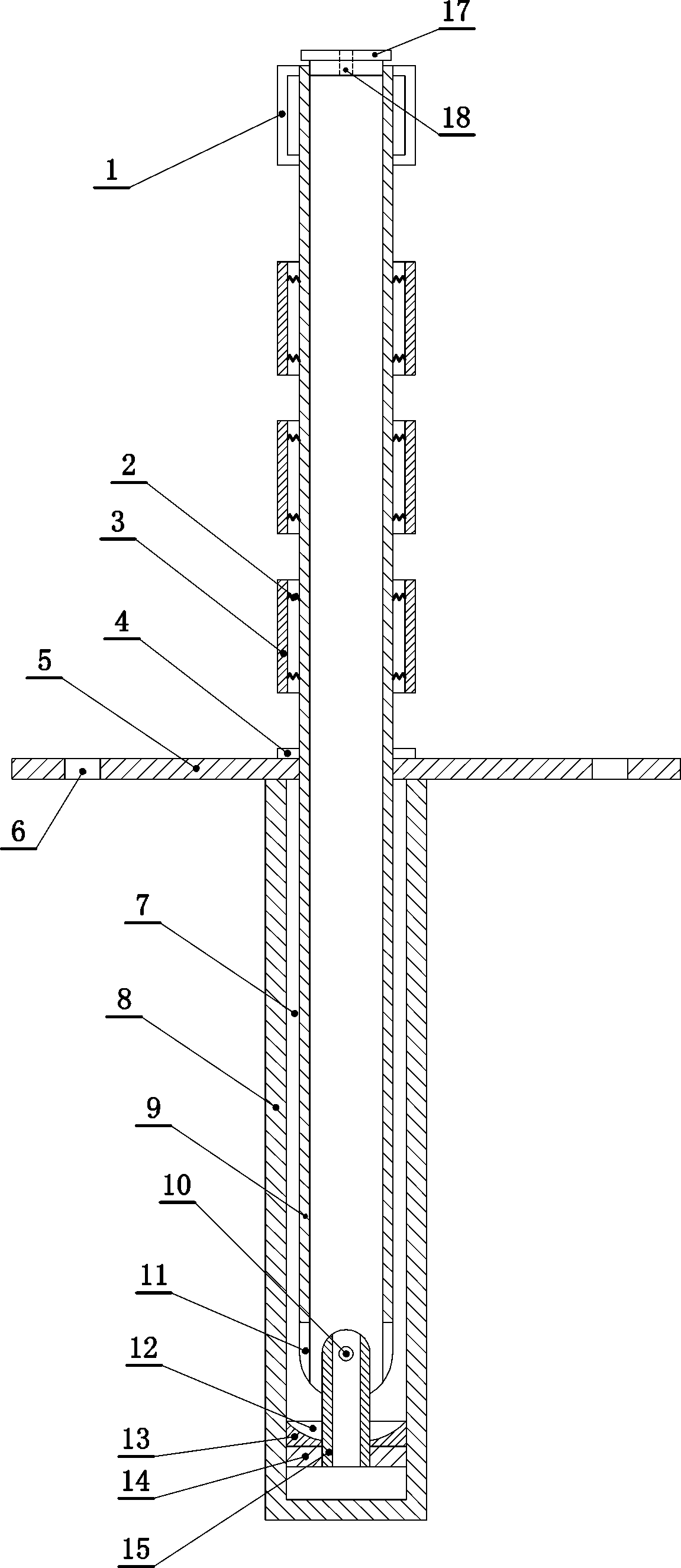

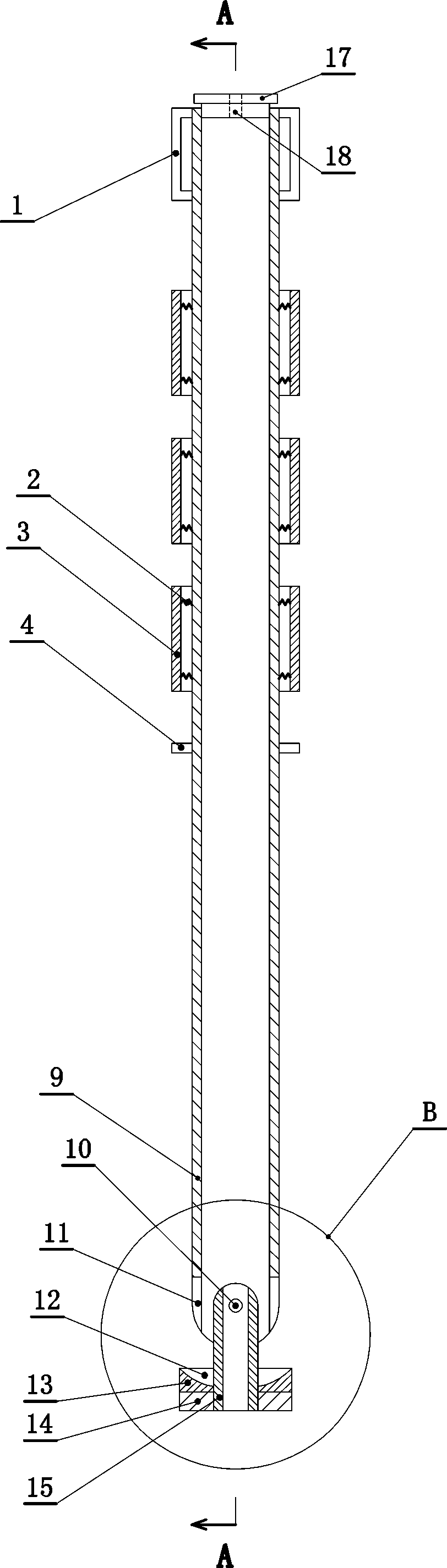

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

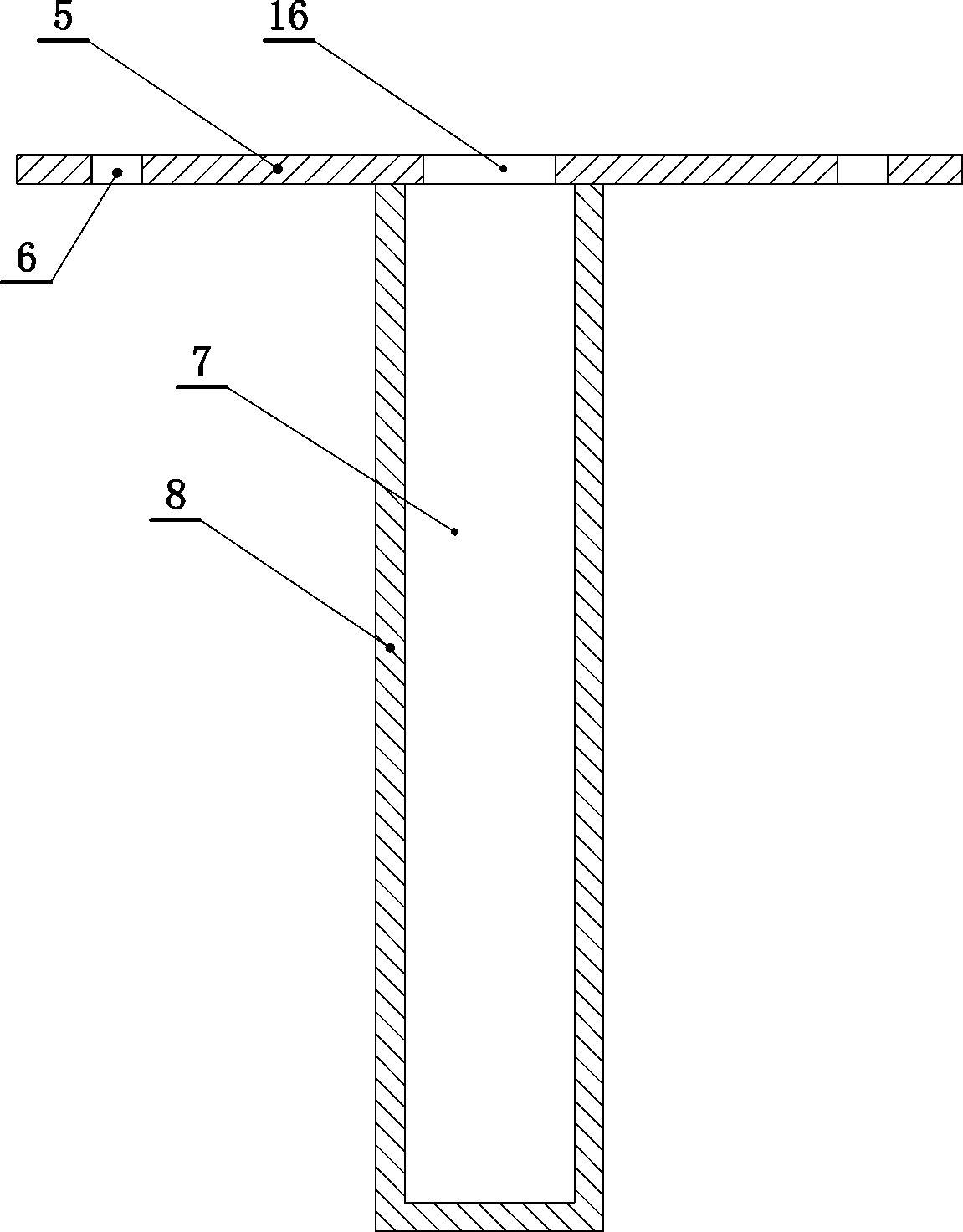

[0029] Such as Figure 1 to Figure 8 As shown, a plug-in type mine car stop device includes a base, and the base includes a mounting plate (5), which is installed horizontally, and the mounting plate (5) is fixedly installed between two rails for the mine car On the ground passing along the way, there are fixing holes (6) arranged transparently up and down on the installation fixing plate (5), and a plurality of fixing holes (6) are set on the installation fixing plate (5) around the guide limit hole (16). ), and the fixing plate (5) can be easily fixed on the ground through the fixing hole (6).

[0030] The installation fixed plate (5) is provided with a guide limit hole (16) transparently set up and down, the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com