A vibration damping device for a loader

A vibration damping device and loader technology, which is applied to earth movers/excavators, construction, etc., can solve the problems of weak boom, failure to work normally, sudden extension of the boom cylinder, etc., and achieve good cushioning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

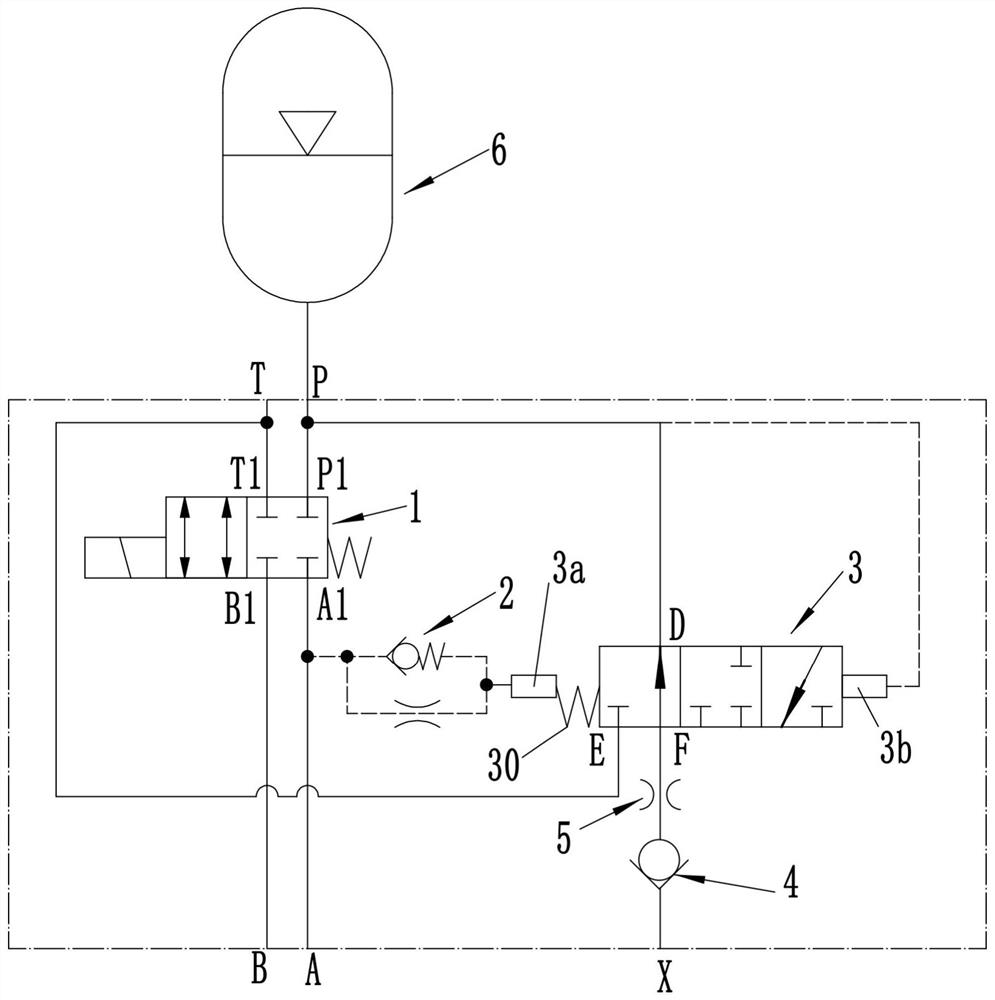

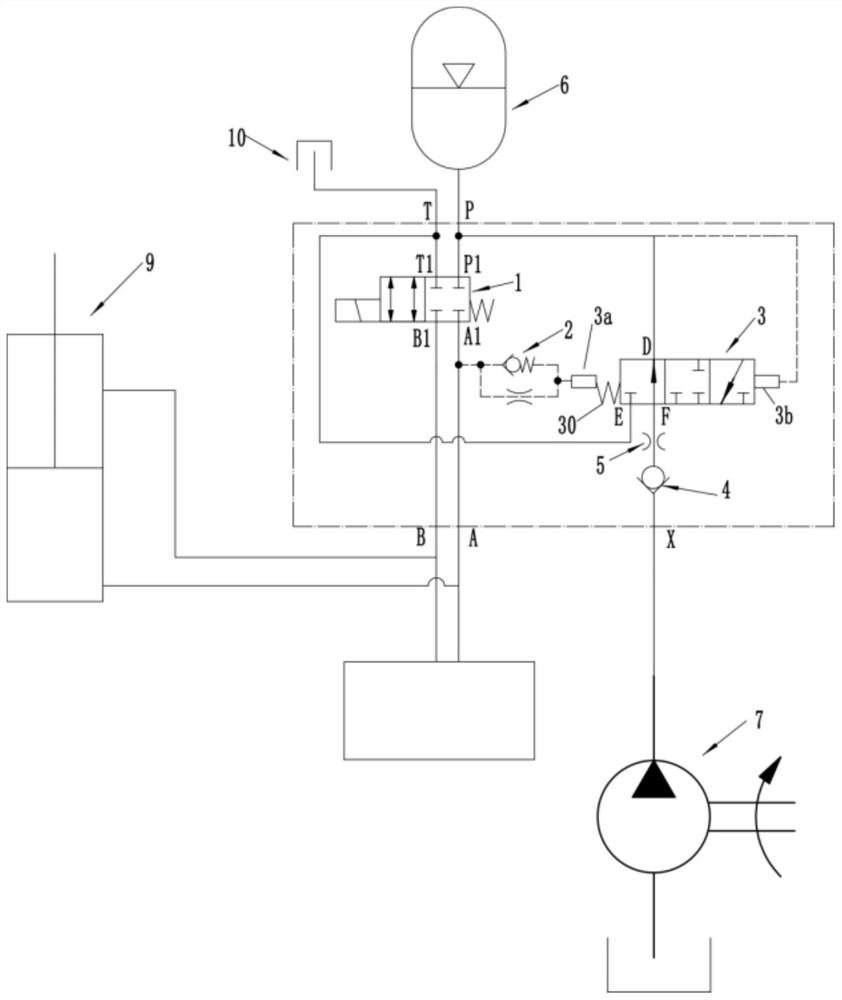

[0019] see Figure 1-2 As shown, it includes a two-position four-way electromagnetic reversing valve 1, a pressure control valve, and an accumulator 6. The P1 port of the two-position four-way electromagnetic reversing valve 1 communicates with the accumulator 6, and the T1 port communicates with the fuel tank 10. , A1 port communicates with the rodless chamber of the boom cylinder 9, B1 communicates with the rod chamber of the boom cylinder 9; when the coil of the two-position four-way electromagnetic reversing valve 1 is energized, the P1 port communicates with the A1 port, and the B1 port communicates with the A1 port. The port is connected with the T1 port; when the coil of the two-position four-way electromagnetic reversing valve 1 is de-energized, the A1 port, P1 port, T1 port, and B1 port are not connected to each other; the pressure control valve is used to control the pressure of the P1 port and the A1 port same mouth pressure.

[0020] The pressure control valve is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com