Assembled handrail convenient to install

An easy-to-install and assembled technology, which is applied in the direction of railings, railing posts, building structures, etc., can solve the problems of difficult to guarantee the quality of welding parts, long construction period, and heavy workload, so as to improve the reuse rate and eliminate potential safety hazards , the effect of a high degree of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

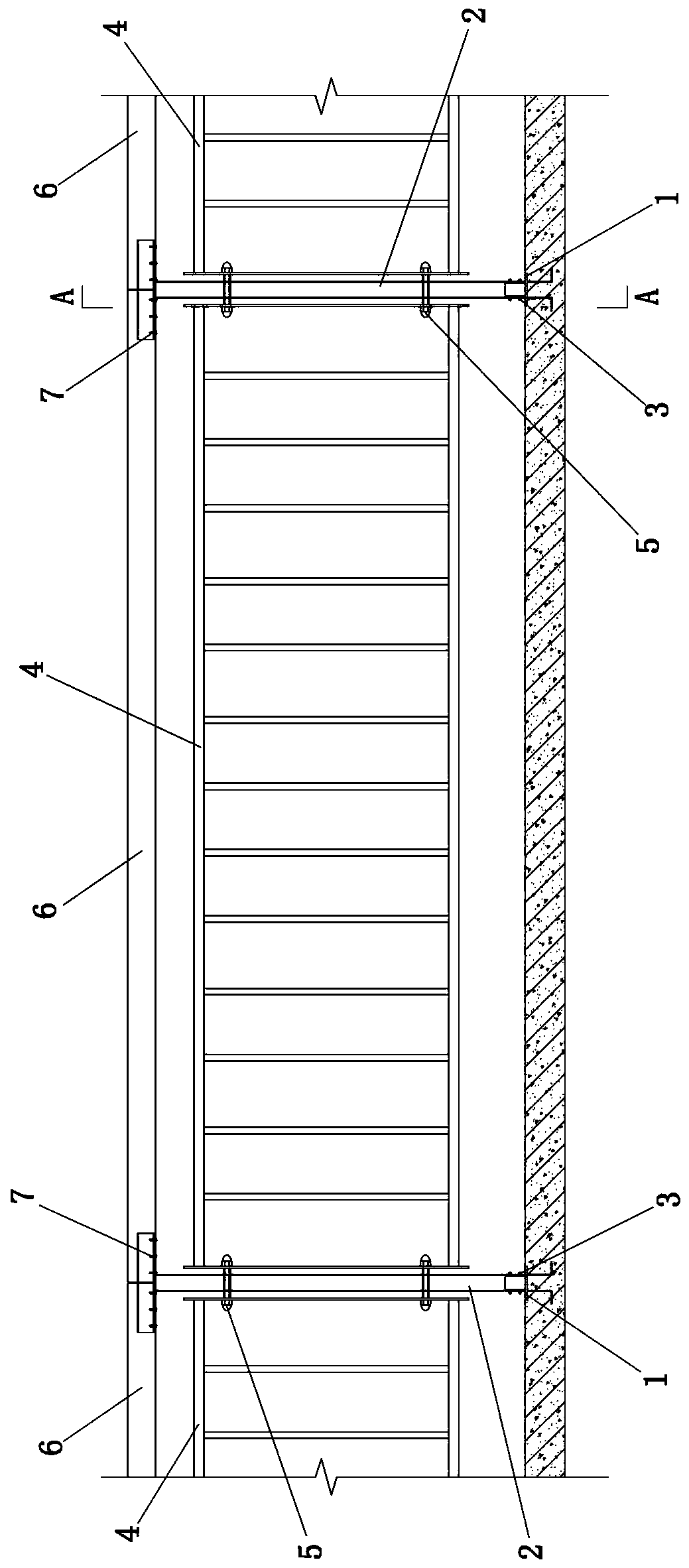

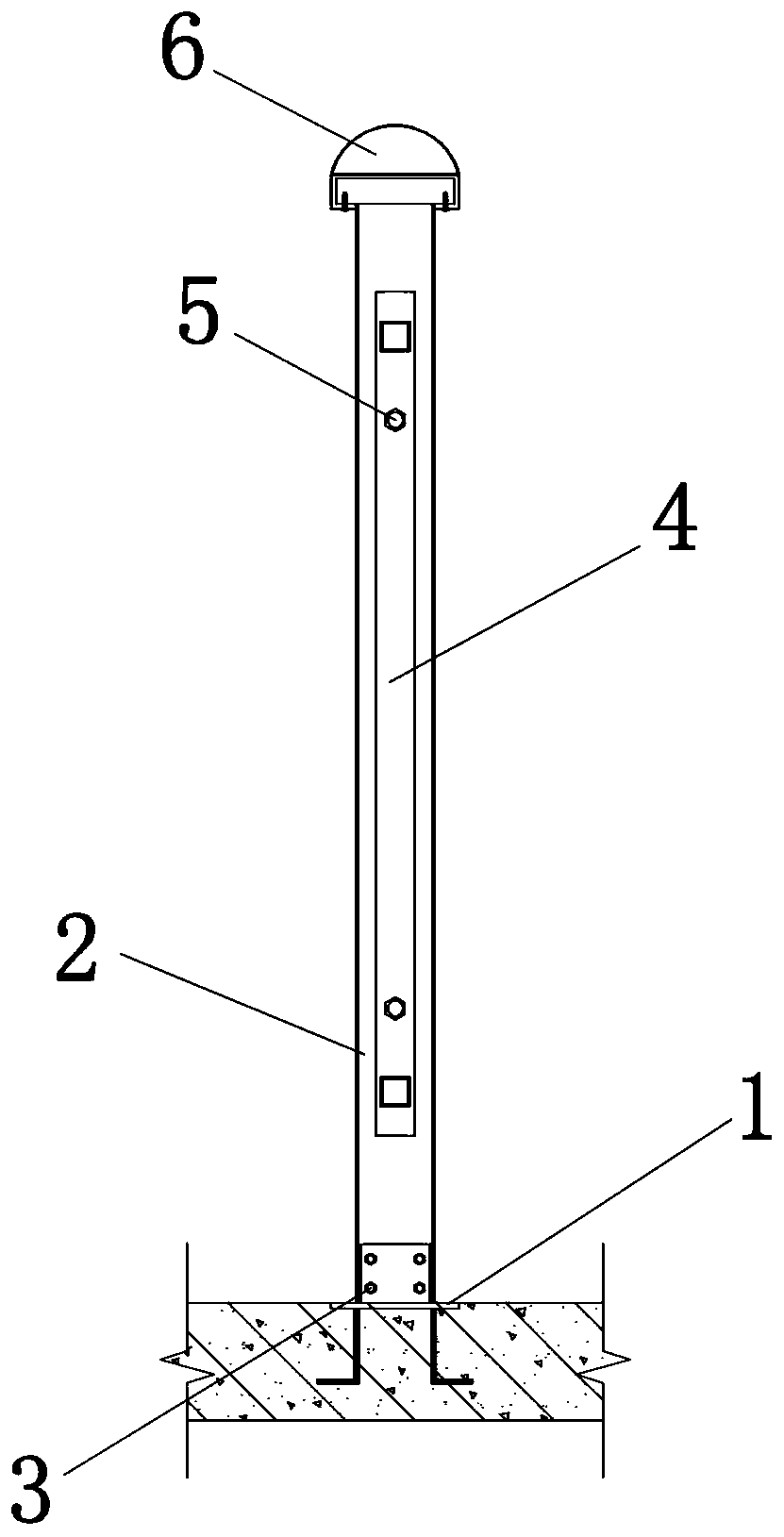

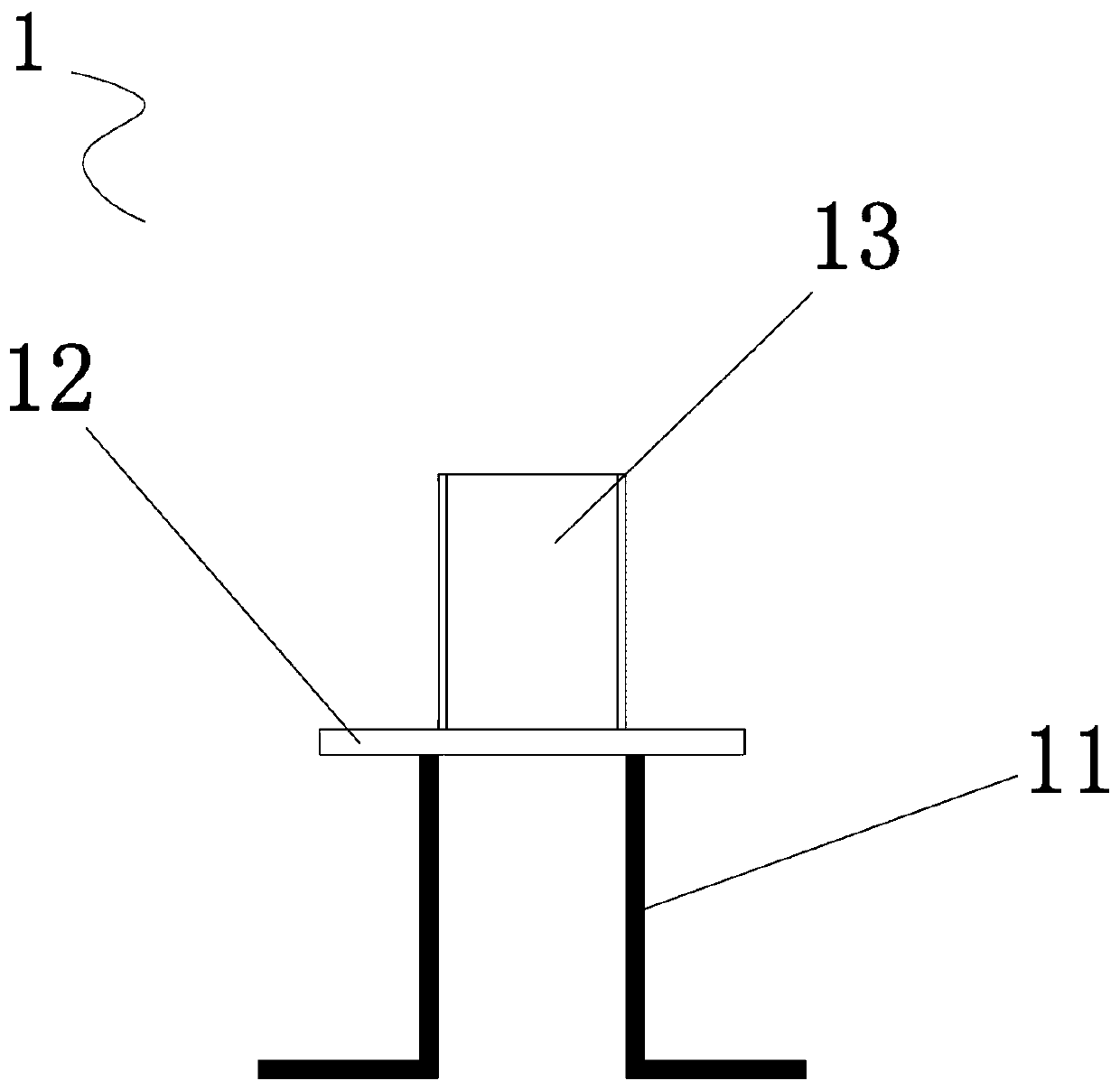

[0020] An assembled railing that is easy to install, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, it includes several pre-embedded components 1 arranged at intervals. The pre-embedded components 1 are provided with railing columns 2, and guardrails 4 are connected between two adjacent railing columns 2; Embedded steel bars 11, pre-embedded steel plates 12, pre-embedded steel plates 12 are set on pre-embedded steel bars 11; pre-embedded steel plates 12 are provided with reserved pipes 13, and the bottom of railing columns 2 is connected with reserved pipes 13 through shear bolts 3 The railing column 2 includes a column 21, and the bottom of the column 21 is connected with the reserved pipe 13; the column 21 is provided with more than one connecting hole at intervals; the guardrail 4 includes an upper chord 41, a lower chord 44 arranged at intervals, 41 and the lower chord 44 are provided with a number of webs 42 at intervals, and the left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com