A Method for Determining the Anisotropy Parameters of Pipes

A technology of anisotropy and determination method, which is applied in the field of pipe performance testing, and can solve the problem of inability to accurately measure the anisotropic characteristic parameters of pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

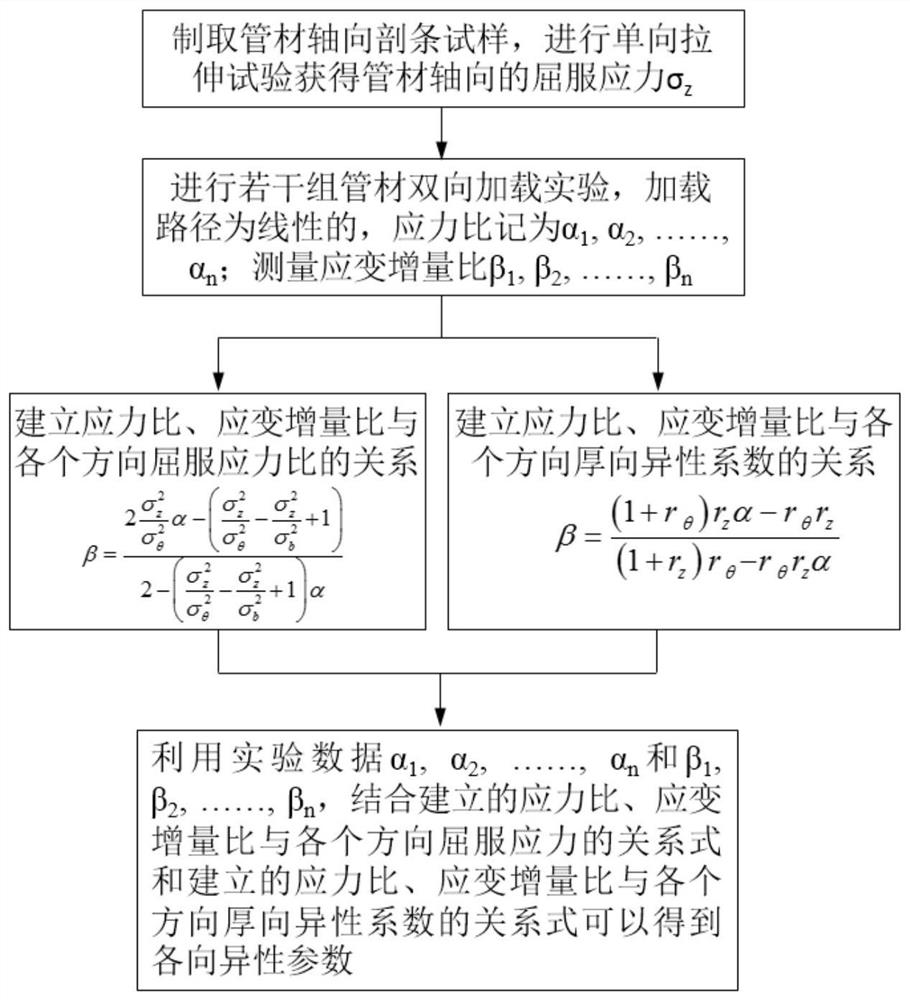

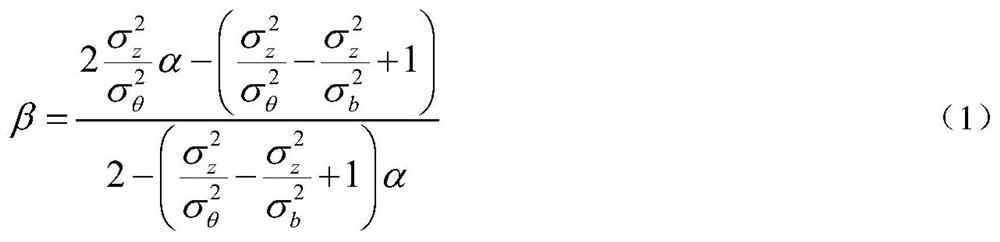

[0053] Take the 6061F aluminum alloy extruded pipe with an outer diameter of 40mm and a wall thickness of 1.2mm as an example. figure 1 The implementation process of the present invention is described:

[0054] Step 1: Cut a sectioned sample along the axial direction of the pipe, and perform a uniaxial tensile test to obtain the yield stress σ in the axial direction of the pipe z =94.1MPa;

[0055] Step 2. Cut the pipe to be tested into a suitable length, the length is 270mm, and carry out two sets of pipe bidirectional loading experiments. The loading path is linear, recorded as α=0.25, 1.0, and the measured strain increment ratio β=-0.1662, 0.4356 ;

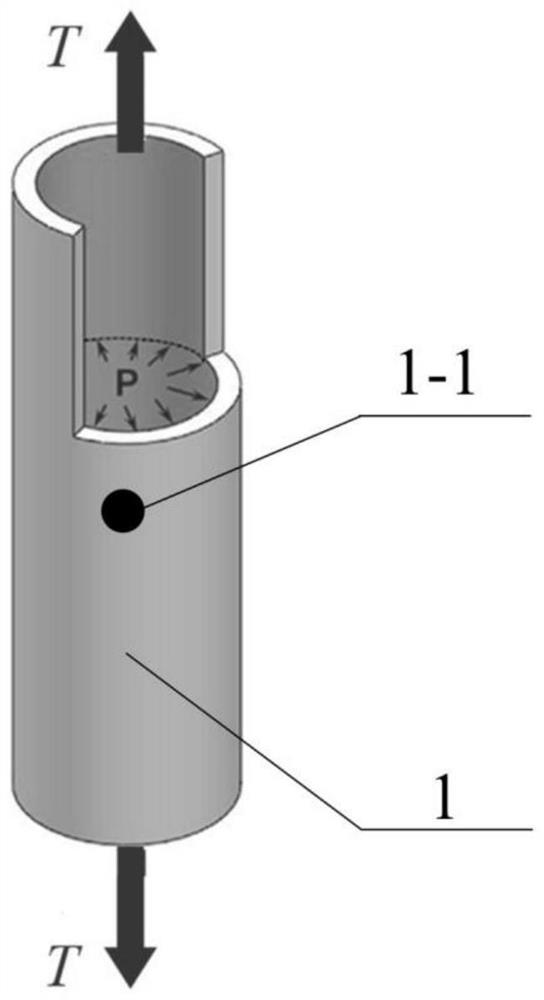

[0056] The pipe bidirectional loading experiment is carried out on a special pipe bidirectional loading experiment test device (refer to patent CN105300802B), applying a tensile or compressive l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com