Vibration and noise reduction dynamic shock absorber for rail vehicle wheel set

A technology for a dynamic vibration absorber and a rail vehicle, applied in the field of rail transit, can solve problems such as vibration and noise, and achieve the effects of preventing safety problems, occupying less space, and having a compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

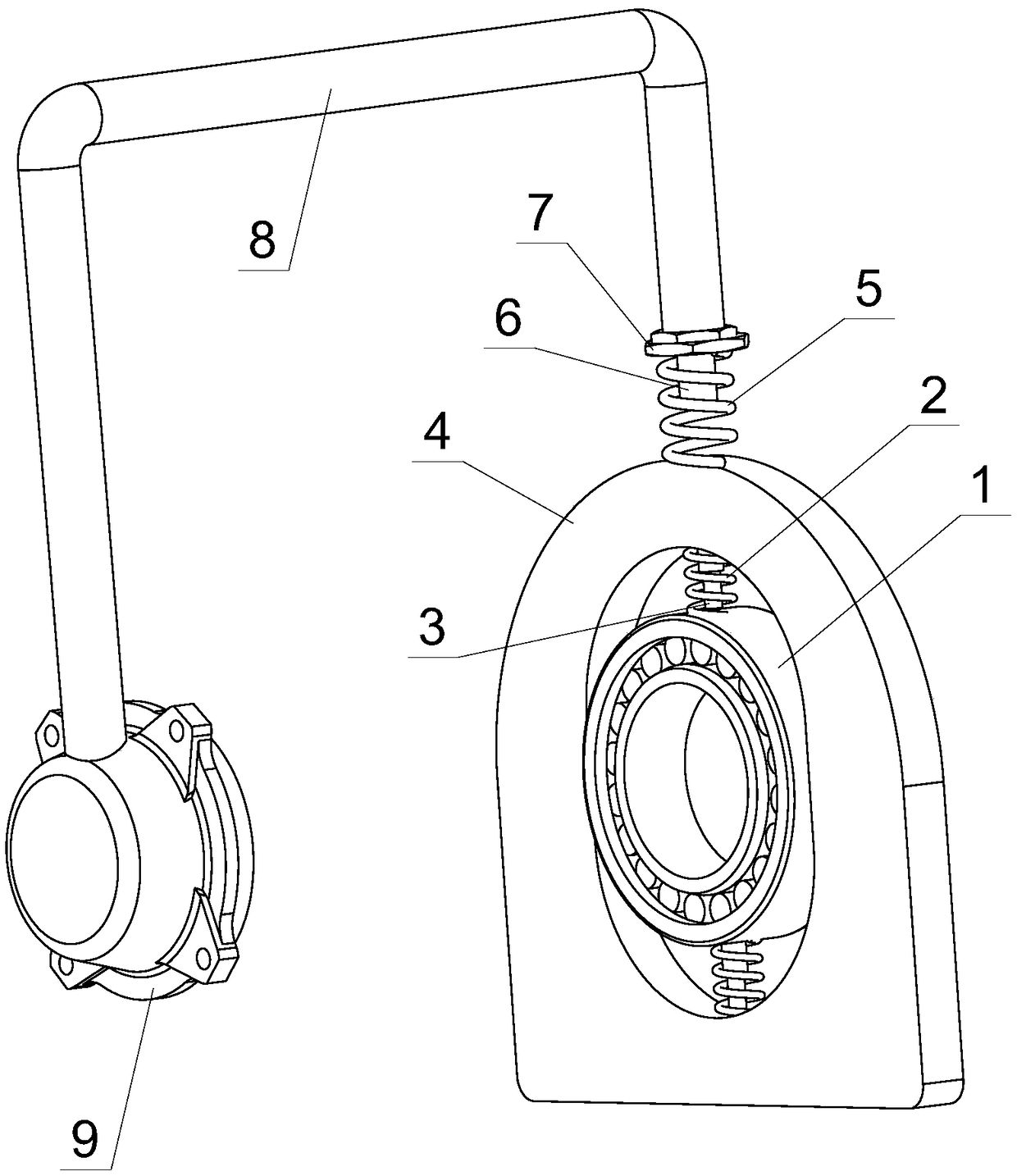

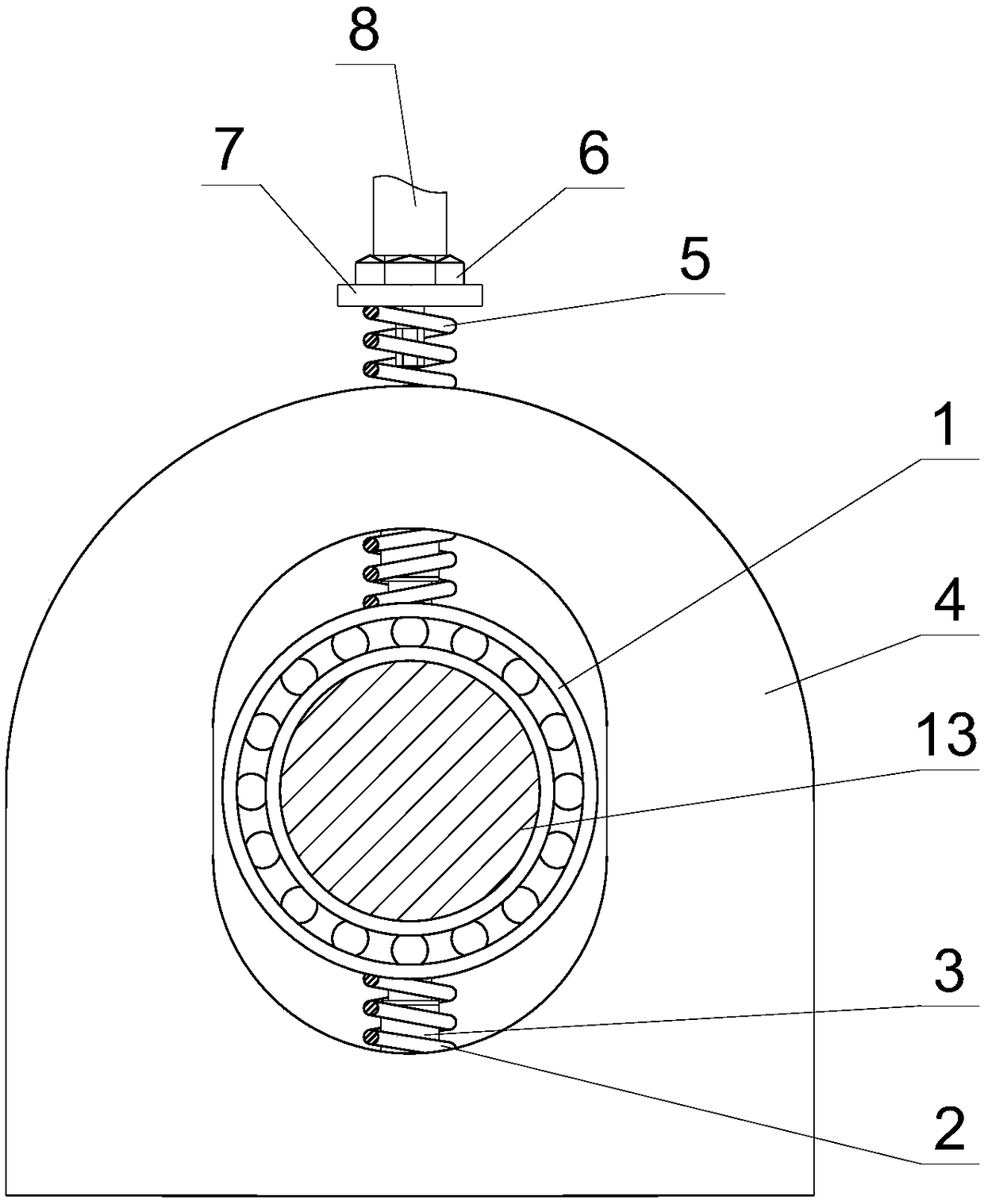

[0043] The present invention will be further described below in conjunction with accompanying drawing.

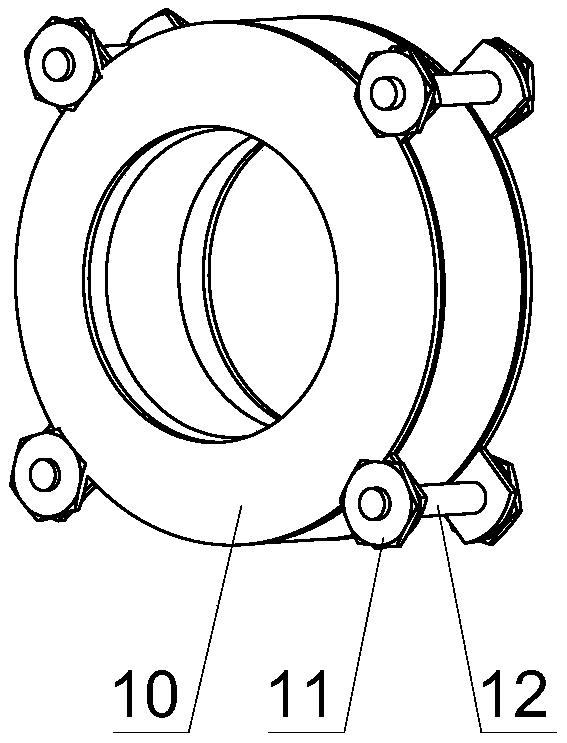

[0044] Such as Figure 4~6 The rail vehicle wheel set shown includes an axle 13 and two wheels arranged near the two ends of the axle 13, and axle boxes are arranged at the ends of the axle 13.

[0045] Such as Figure 1~3 The damping and noise-reducing power shock absorber of the rail vehicle wheel set shown is that the crankshaft 8 of reverse "U" shape opens downward, and one end is fixed on the axle box end cover 9 at one end of the axle shaft 13, and the other end is connected from the rail vehicle underframe. The gap between the frame and the frame passes through, and the inner side of the wheel corresponding to the axle box is bent downward, and the end is fixed with the big end of the bolt 6 as a whole; the nut 7 wrapped on the bolt 6 presses the bolt 6 large The end is screwed on the bolt 6; the upper spring wire of the vertically fixed spring 5 is fixed on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com