Method for realizing digital twin modeling of automatic circuit breaker assembling workshop

A circuit breaker assembly and assembly workshop technology, applied in the direction of instruments, comprehensive factory control, comprehensive factory control, etc., can solve the lack of automation and information operation methods, the inability to dynamically and timely grasp the operating status of the workshop, and the low transparency of the production line, etc. problems, to achieve the effect of improving real-time operation level, enhancing transparency and management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

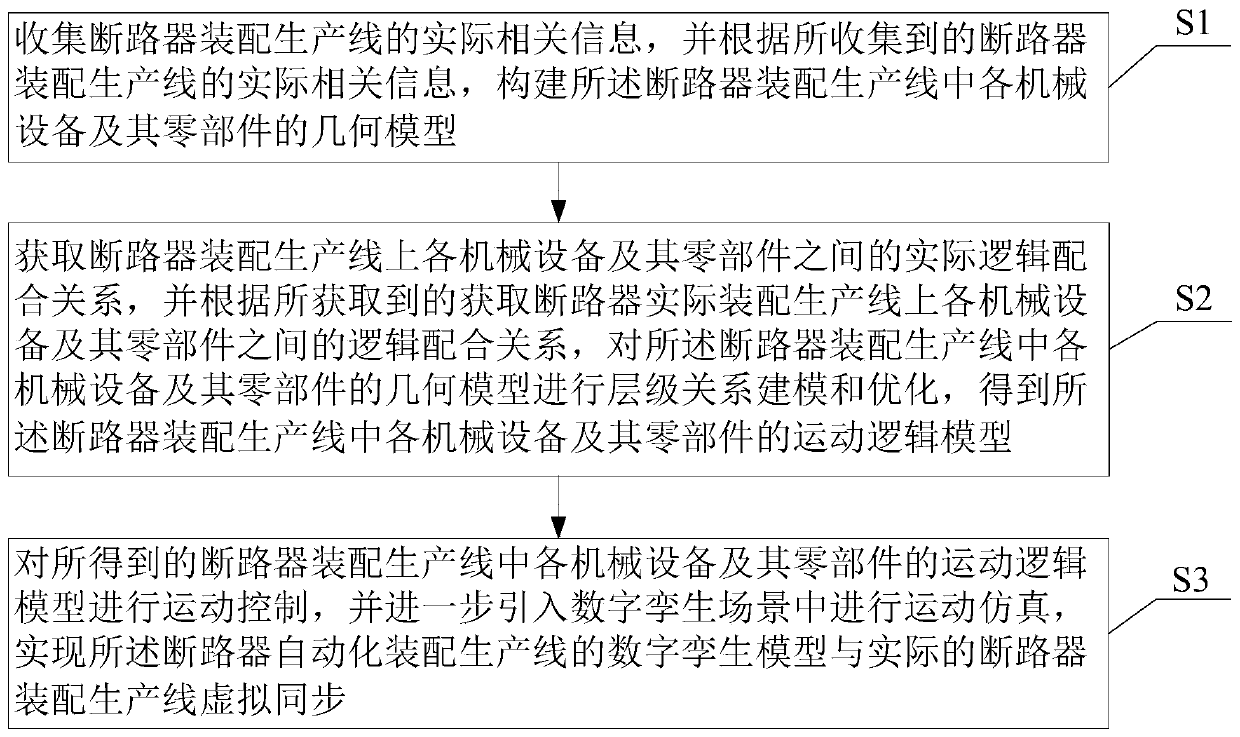

[0036] Such as figure 1 As shown, in the embodiment of the present invention, a method for realizing the digital twin modeling of the circuit breaker automatic assembly workshop is provided, and the method includes the following steps:

[0037]Step S1, collecting actual relevant information of the circuit breaker assembly line, and constructing a geometric model of each mechanical device and its components in the circuit breaker assembly line according to the collected actual relevant information of the circuit breaker assembly line;

[0038] The specific process is as follows. First, collect the actual relevant information of the circuit breaker assembly line, including the layout information of the physical workshop, and the geometric dimensions, movement distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com