Equipment residual life prediction method and system

A technology for life prediction and equipment, applied in computer-aided design, design optimization/simulation, instruments, etc., to achieve the effect of improving prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

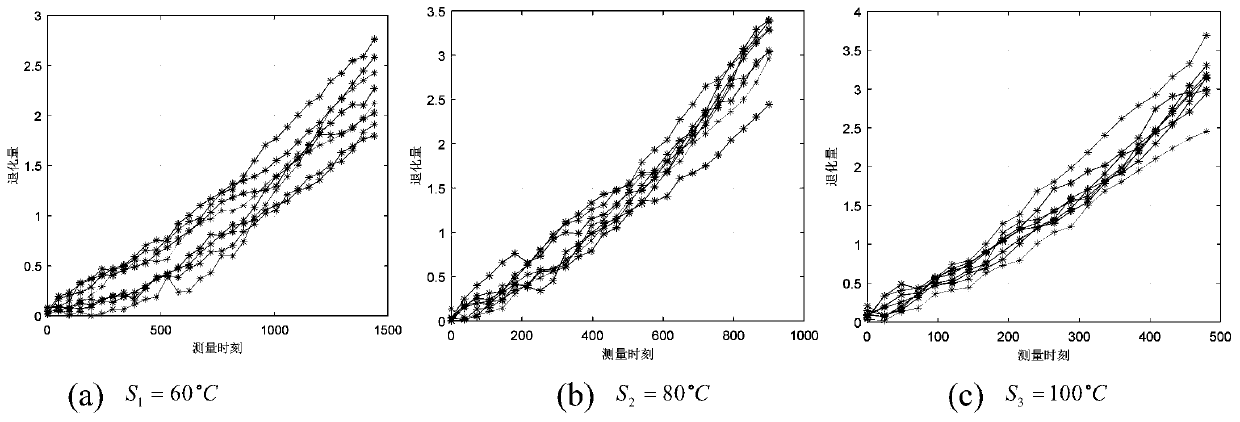

[0167] Taking a certain type of military electrical connector as an example, verify the effectiveness of the proposed method of the present invention, the verification object includes the method for predicting the remaining life of equipment based on the fusion of accelerated degradation data and actual degradation data proposed by the present invention (denoted as m 1 ), the residual life prediction method based on Wiener process fusion accelerated degradation data and actual degradation data (denoted as M 2 ) and the remaining life prediction method based on logarithmic transformation data lnX(t) (denoted as M 3 ).

[0168] The normal working stress S of the sample 0 = 20°C, 24 samples were randomly selected, respectively under three kinds of accelerated stress S 1 =60°C, S 2 =80°C, S 3 = The accelerated degradation test was performed at 100°C, and 8 samples were assigned to each stress. Assume that at stress S 1 30 measurements are taken at intervals of 48 hours; at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com