Windscreen lifter with lifting function

A wiper and functional technology, applied in the field of wiper, can solve the problems of natural ecological environment damage, increase of car cost, discarded wiper, etc., to avoid high temperature baking, increase service life, and increase durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

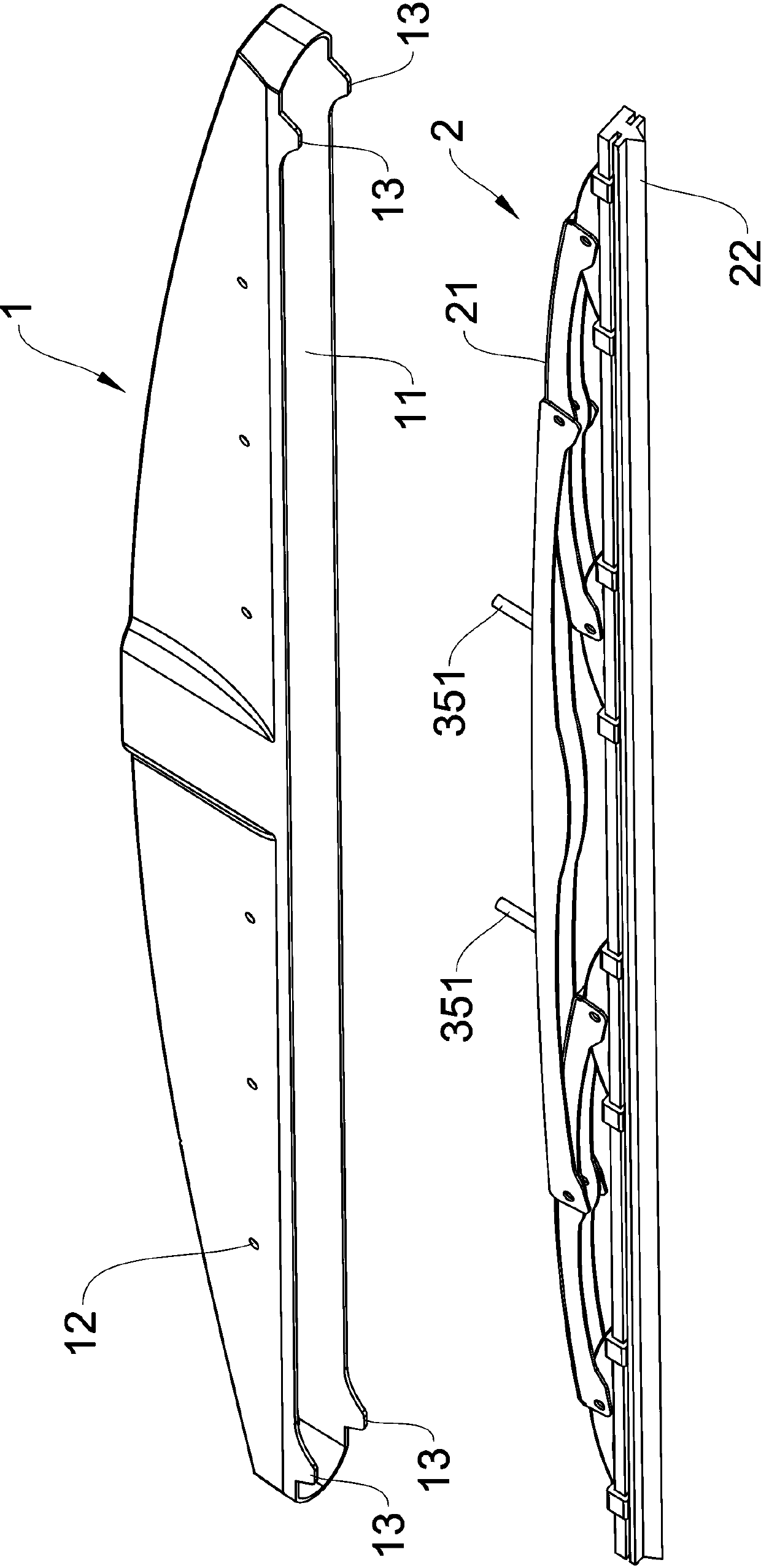

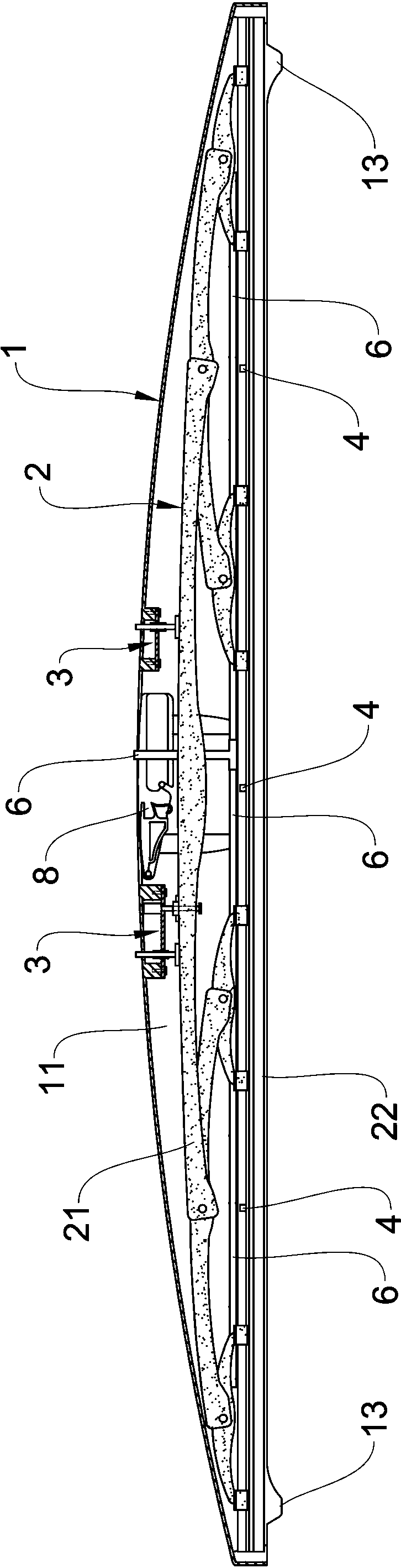

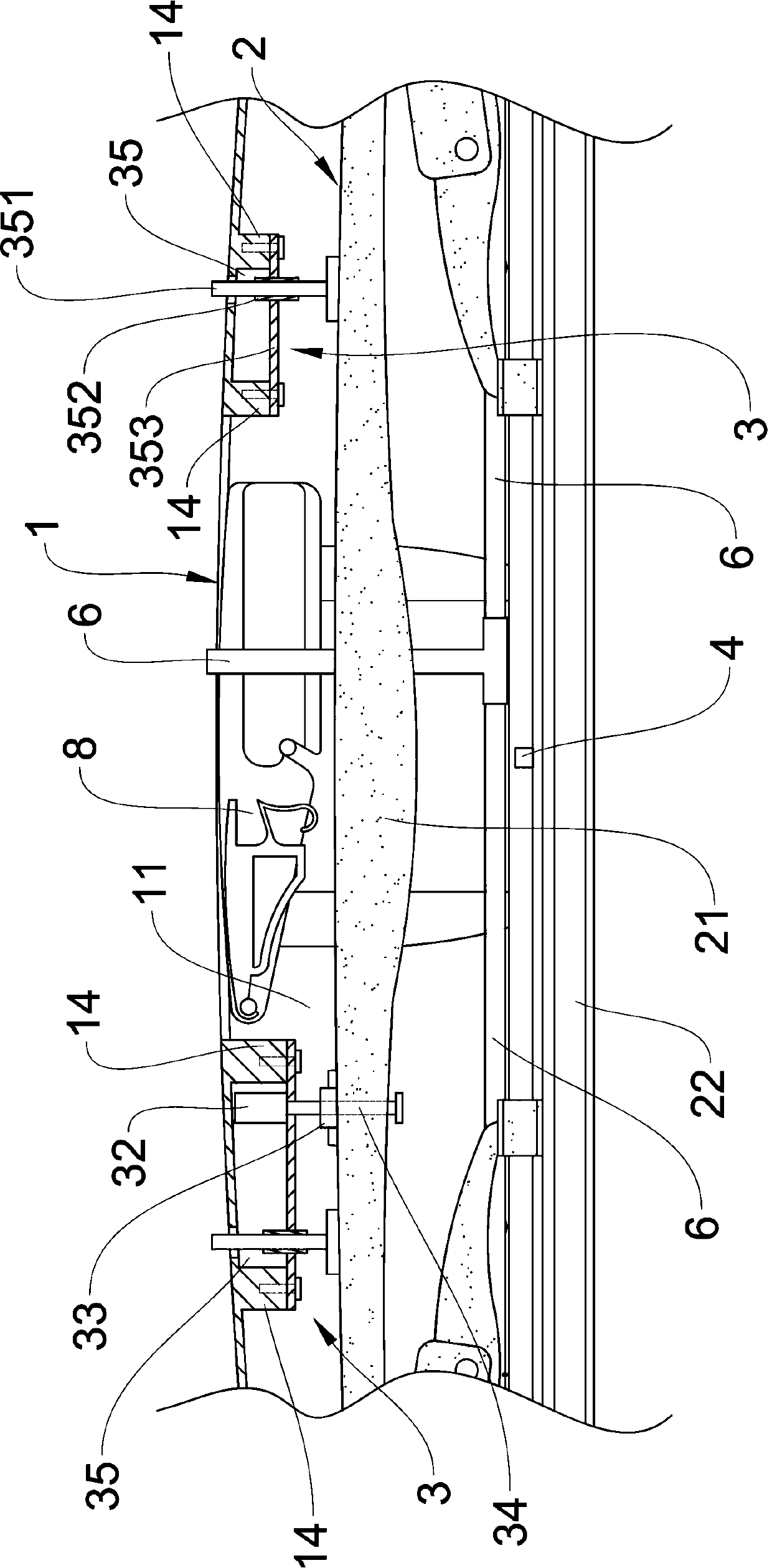

[0021] Such as Figure 1 to Figure 5 As shown, a wiper blade with a lifting function according to the present invention includes a protective cover 1 and a wiper 2, wherein the protective cover 1 is provided with a cavity 11 for accommodating the wiper 2, and the wiper 2 is arranged on In the cavity 11, between the top of the wiper 2 and the inner top wall of the cavity 11, there is also a push mechanism 3 that can make the wiper 2 extend out of the cavity 11 or retract into the cavity 11. On the top of the protective cover 1 There is also a fastening hole 8 for fastening with the wiper swing arm on the car. The structure of this fastening hole 8 is basically the same as the structure of the fastening hole on the traditional wiper.

[0022] Among them, such as figure 2 and image 3 As shown, the pushing mechanism 3 can be composed of a micro numerical control motor 32 , a gear 33 , a screw or a rack 34 , and a pushing bracket 35 . Concretely can be assembled like this, pus...

Embodiment 2

[0029] The difference between the second embodiment and the first embodiment is that the protective cover is canceled and the telescopic support feet are added so that the wiper can be separated from the glass surface without brushing the glass surface. Contact, reduce glass high-temperature baking and heat transfer, delay the aging of the wiper rubber strip of the wiper, and achieve the purpose of prolonging its service life. The specific scheme of present embodiment two is like this: as Figure 6 and Figure 7 or Figure 8 and Figure 9 As shown, a wiper blade with a lifting function includes a wiper blade 2 , and a push mechanism 3 is provided on the top of the wiper blade 2 .

[0030] Among them, such as Figure 6 and Figure 7 As shown, the pushing mechanism 3 is composed of a micro numerical control motor 32 , a gear 33 , a screw or a rack 34 , a screw seat or a rack seat 36 . Specifically, it can be assembled in such a way that the miniature numerical control moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com