Analysis system

An analysis system and analysis device technology, which is applied in the field of analysis systems for analyzing samples, can solve problems such as mechanical abnormalities and pressure data abnormalities, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

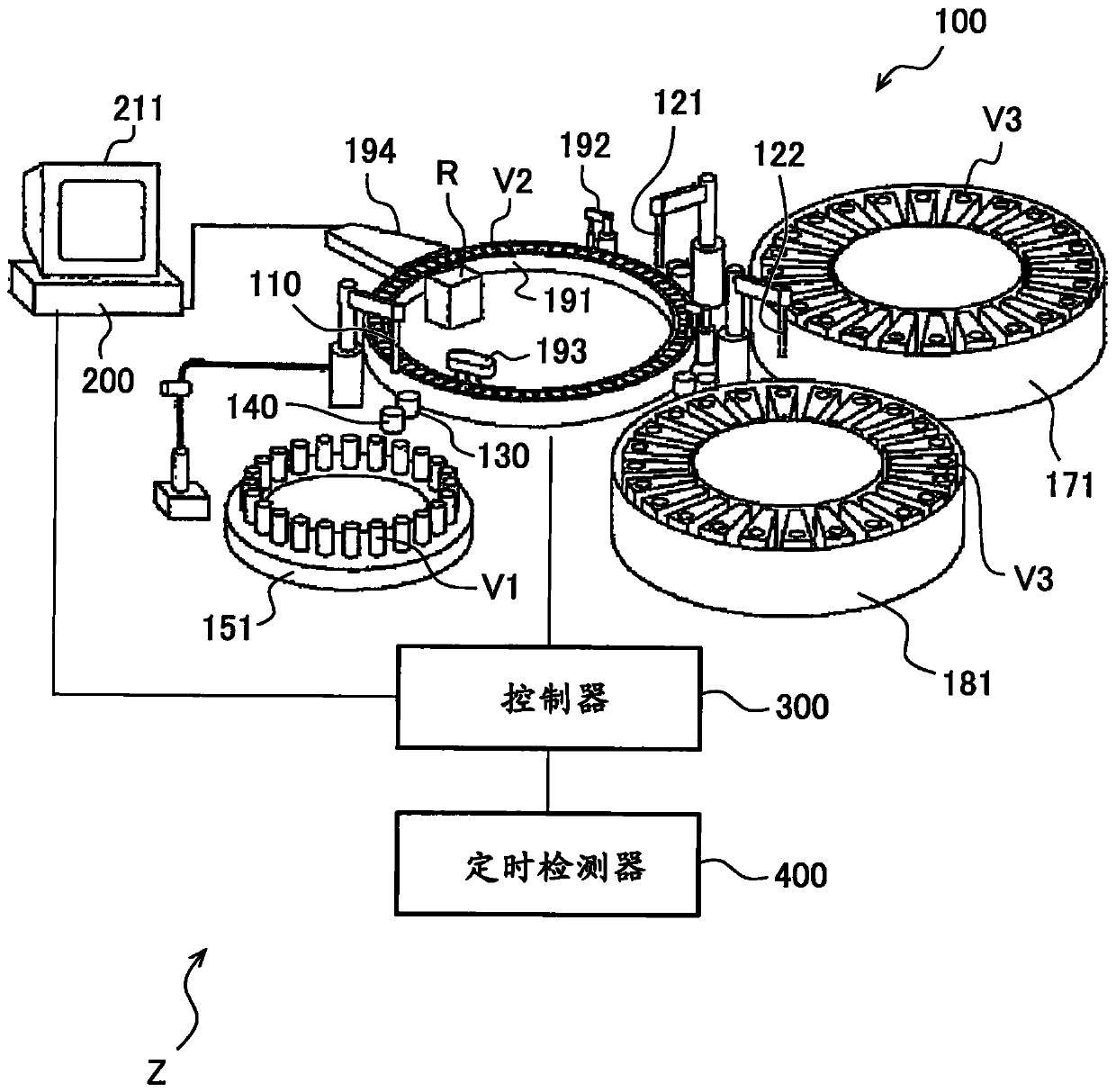

[0055] [Analysis System Z]

[0056] figure 1 It is a schematic configuration diagram of the analysis system Z of the first embodiment.

[0057] The analysis system Z includes an analysis device 100 , a computer (processing unit) 200 , a controller 300 , and a timing detector 400 .

[0058] The analysis device 100 includes a sample disk 151 , a first reagent disk 171 , a second reagent disk 181 , and a reaction disk 191 .

[0059] The sample disk 151 holds a sample container V1 for holding a sample. The first reagent disc 171 and the second reagent disc 181 hold reagent containers V3 for holding reagents. The reaction vessel V2 is held on the circumference of the reaction disk 191 .

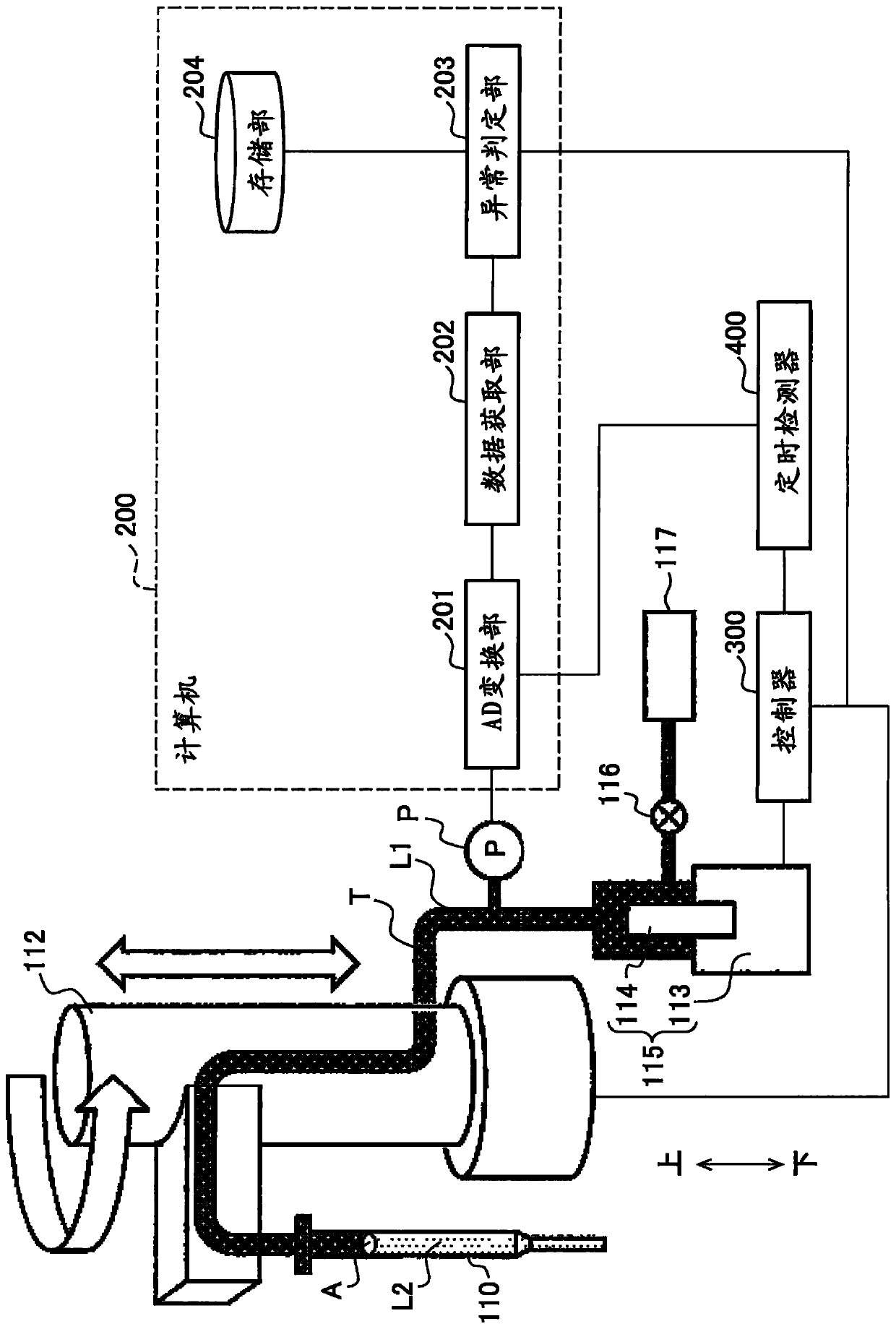

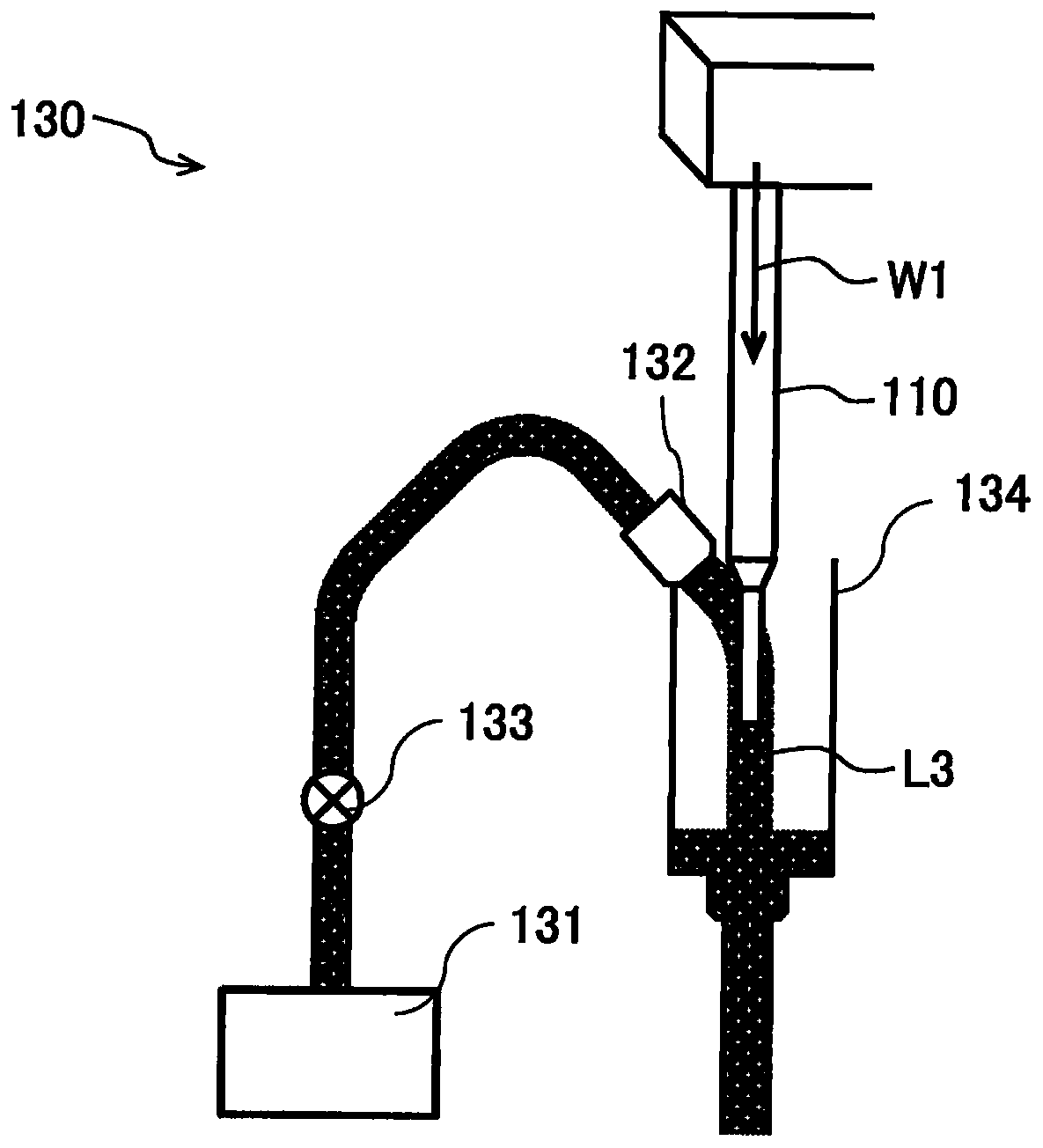

[0060] The analysis device 100 further includes a sample probe 110 , a first reagent probe 121 , a second reagent probe 122 , a cleaning unit 130 , a drying unit 140 , a stirring device 192 , a container cleaning unit 193 , and a light source R. In addition, for the cleaning part 130 and the ...

no. 2 approach

[0193] As the main cause of the change in the pressure data of the analysis device 100, differences in installation conditions and operating conditions of the analysis device 100 can be cited. For example, depending on the ambient temperature, humidity, air pressure, and temperature of supplied pure water (system fluid L1 ) at the location where the analyzer 100 is installed, the pressure data may vary even under the same operating conditions. Therefore, when calculating the determination parameters, it is necessary to prepare pressure data acquired under various environmental conditions. On the other hand, determination parameters acquired for various environmental conditions tend to have lower determination accuracy than determination parameters calculated from pressure data obtained under specific environmental conditions. Therefore, it is most preferable to select an appropriate determination parameter according to the installation conditions and operation conditions of th...

no. 3 approach

[0206] In addition, as the determination parameter group selection method as in the second embodiment, different parameter groups may be selected for each operation.

[0207] That is, the determination score of each action is calculated for each determination parameter, and the parameter group with the smallest determination score (second condition) is selected among each action. For example, choose a combination such that the Figure 10 Select parameter e in the "external cleaning fluid spray confirmation", select parameter e in the "drying function confirmation", select parameter b in the "up and down rotation action confirmation" (in Figure 10 indicated by circle marks).

[0208] Thereby, abnormality determination can be performed using the optimum determination score for each operation. Accordingly, it is possible to improve the avoidance accuracy of erroneous determination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com