A start-up recovery method of a generator set when the booster fan is not mechanically abnormal

A booster fan and generator set technology, which is applied to steam generation, lighting and heating equipment, control systems, etc., can solve the problems of shortening generator sets, etc., and achieve the effects of increasing diversity, reducing start-up costs, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

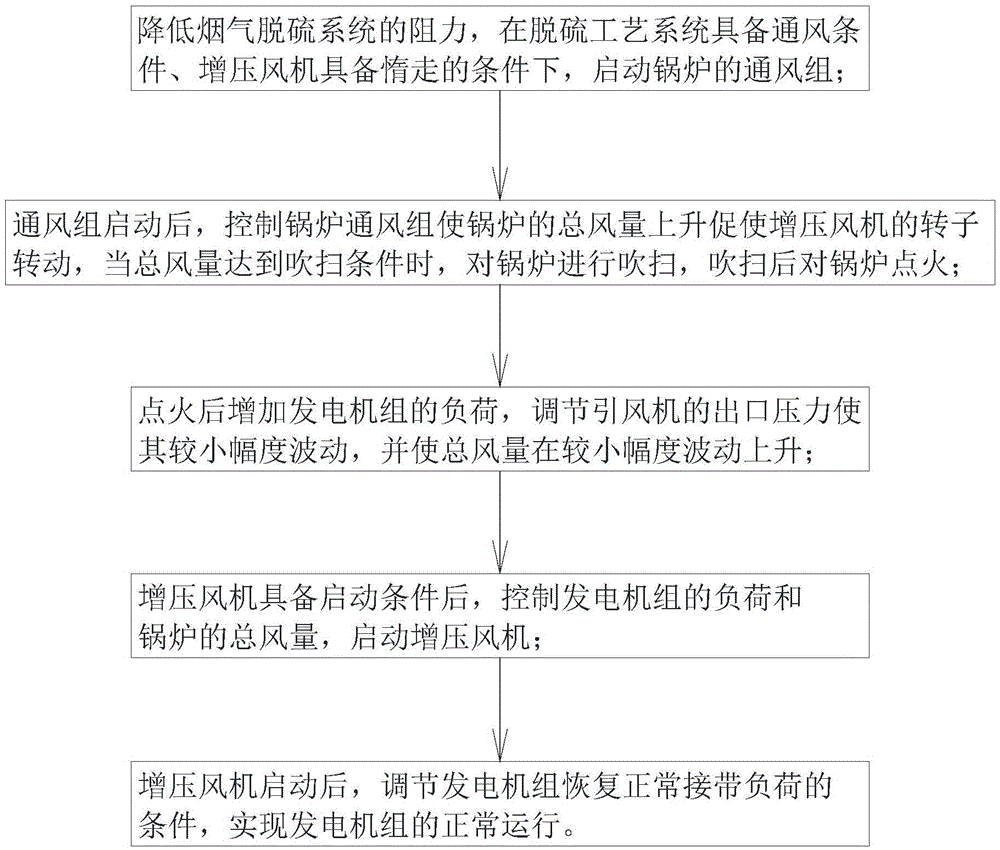

[0035] Embodiment 1 of the present invention: a method for starting and restoring a generator set when the booster fan is not mechanically abnormal, which is characterized in that it includes the following steps:

[0036] Step 1: Reduce the resistance of the flue gas desulfurization system, and start the ventilation group of the boiler under the condition that the desulfurization process system has ventilation conditions and the booster fan has idle running;

[0037] Step 2: After the ventilation group is started, control the boiler ventilation group to increase the total air volume of the boiler and prompt the rotor of the booster fan to rotate. When the total air volume reaches the purging condition, the boiler is purged, and the boiler is ignited after purging;

[0038] Step 3: After ignition, increase the load of the generator set, continuously control the outlet pressure of the induced draft fan to make it fluctuate in a small range, and make the total air volume rise in a...

specific Embodiment 2

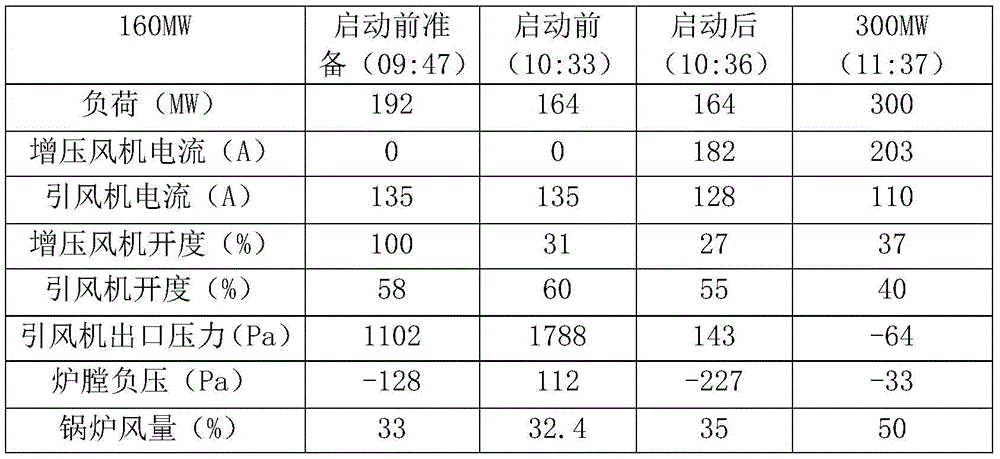

[0053] Specific embodiment two of the present invention: a kind of method for starting and recovering the generator set when the booster fan of the 600MW unit is not mechanically abnormal, comprising the following steps:

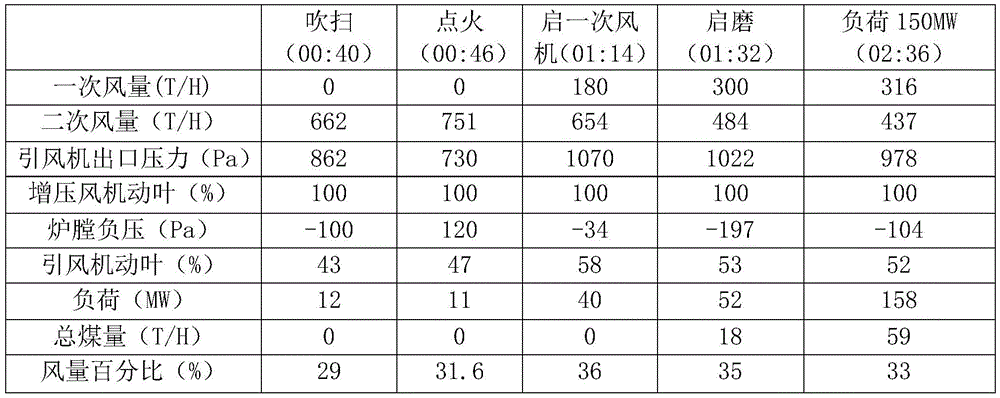

[0054] Step 1: Reduce the resistance of the flue gas desulfurization system, and start the ventilation group of the boiler under the condition that the desulfurization process system has ventilation conditions and the booster fan has idle running; the ventilation group includes a blower, an induced draft fan, and raw coal for grinding The pulverizing system is used to deliver pulverized coal to the boiler for combustion. When the start-up conditions are met, first start the induced draft fan and the blower fan, and control the negative pressure of the furnace at about 100Pa; then open the movable blade of the blower fan, and make sure that the induced draft fan is adjusted normally, and the outlet pressure of the induced draft fan does not fluctuate greatly; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com