Reverse osmosis membrane alkaline cleaning agent and application thereof

A technology of reverse osmosis membrane and cleaning agent, which is applied in the direction of reverse osmosis, semipermeable membrane separation, osmosis/dialysis water/sewage treatment, etc., which can solve the problems of short storage period, long cleaning time, and insufficient cleaning strength, and facilitate transportation and storage, efficient and quick removal, and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

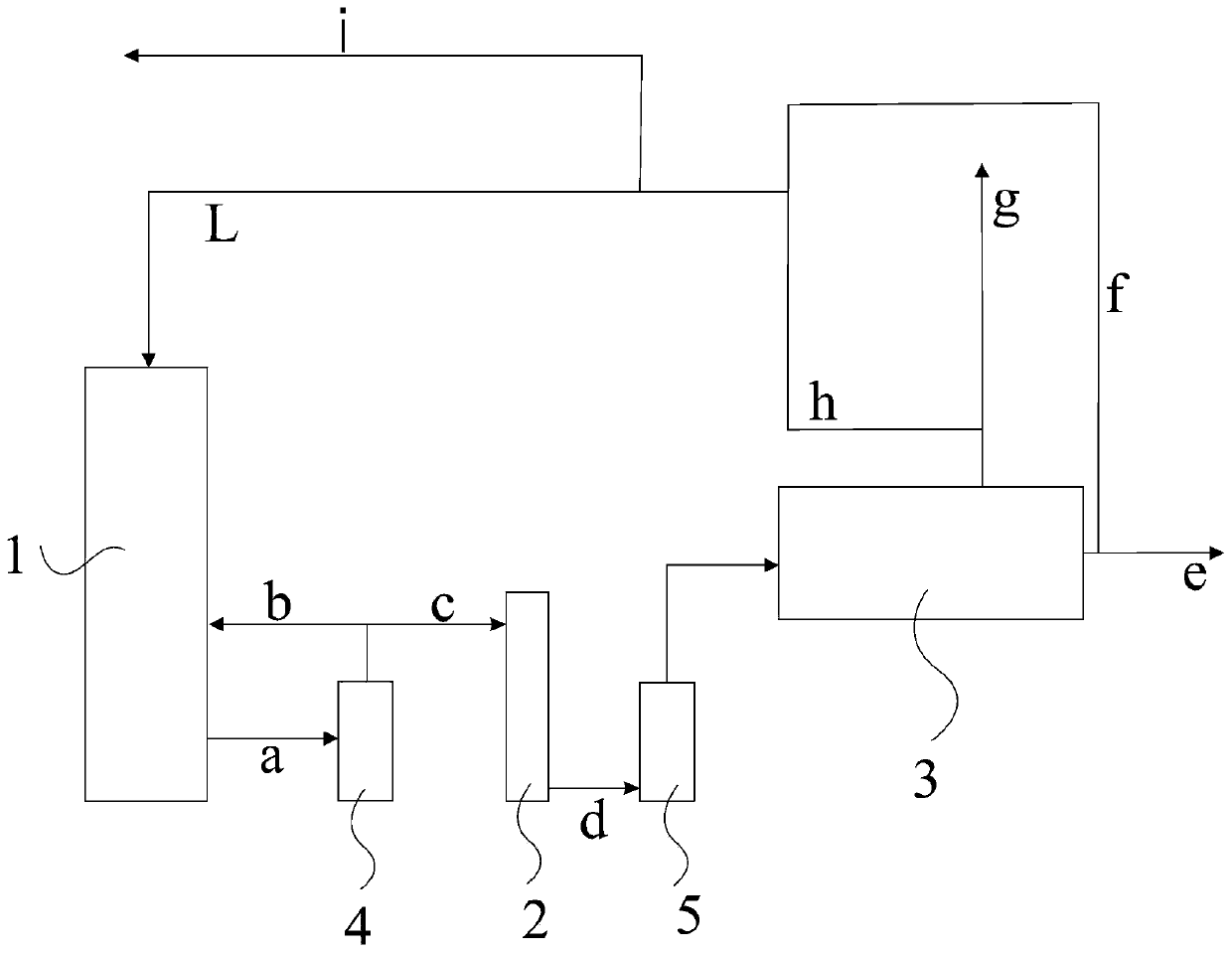

Method used

Image

Examples

Embodiment 1

[0034] A reverse osmosis membrane alkaline cleaning agent comprises the following components in parts by weight:

[0035] 22 parts of sodium hydroxide, 32.5 parts of sodium tripolyphosphate, 16.5 parts of sodium carbonate, 16 parts of tetrasodium edetate, 7 parts of sodium bisulfite, 2 parts of sodium dodecylbenzenesulfonate, 2.5 parts of sodium sulfonate, 1.5 parts of alkaline protease; each component is uniformly mixed with a mixer to obtain a solid powder alkaline cleaning agent for reverse osmosis membrane.

[0036] Among them, alkaline protease (article number: FDG-2202) was purchased from Xiasheng Group, with an enzyme activity of 200,000 u / g.

Embodiment 2

[0038] A reverse osmosis membrane alkaline cleaning agent comprises the following components in parts by weight:

[0039] 18.5 parts of sodium hydroxide, 35 parts of sodium tripolyphosphate, 18 parts of sodium carbonate, 14.5 parts of tetrasodium edetate, 8 parts of sodium bisulfite, 3 parts of sodium dodecylbenzenesulfonate, 2 parts of sodium sulfonate, 1 part of alkaline protease; each component is uniformly mixed with a mixer to obtain a solid powder alkaline cleaning agent for reverse osmosis membrane.

[0040] Among them, alkaline protease (article number: FDG-2202) was purchased from Xiasheng Group, with an enzyme activity of 200,000 u / g.

Embodiment 3

[0042] A reverse osmosis membrane alkaline cleaning agent comprises the following components in parts by weight:

[0043] 20.5 parts of sodium hydroxide, 33.5 parts of sodium tripolyphosphate, 17.5 parts of sodium carbonate, 15 parts of tetrasodium edetate, 7.5 parts of sodium bisulfite, 2.5 parts of sodium dodecylbenzenesulfonate, dodecyl 2.5 parts of sodium sulfonate, 1 part of alkaline protease; each component is uniformly mixed with a mixer to obtain a solid powder alkaline cleaning agent for reverse osmosis membrane.

[0044] Among them, alkaline protease (article number: FDG-2202) was purchased from Xiasheng Group, with an enzyme activity of 200,000 u / g.

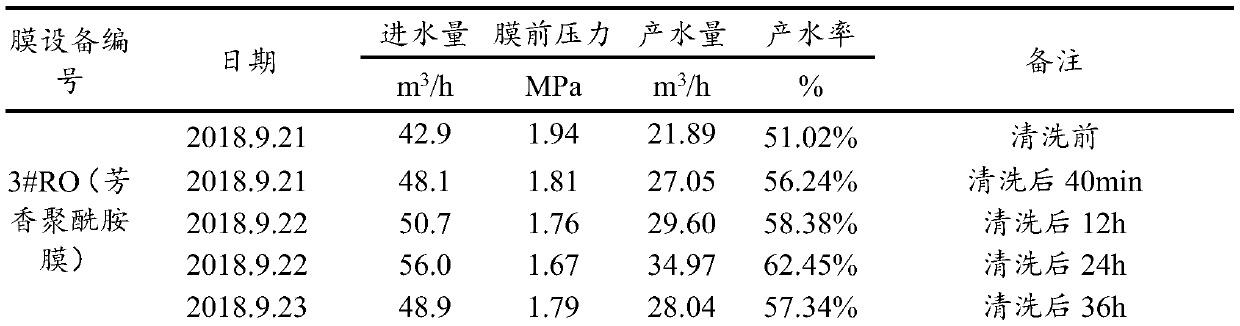

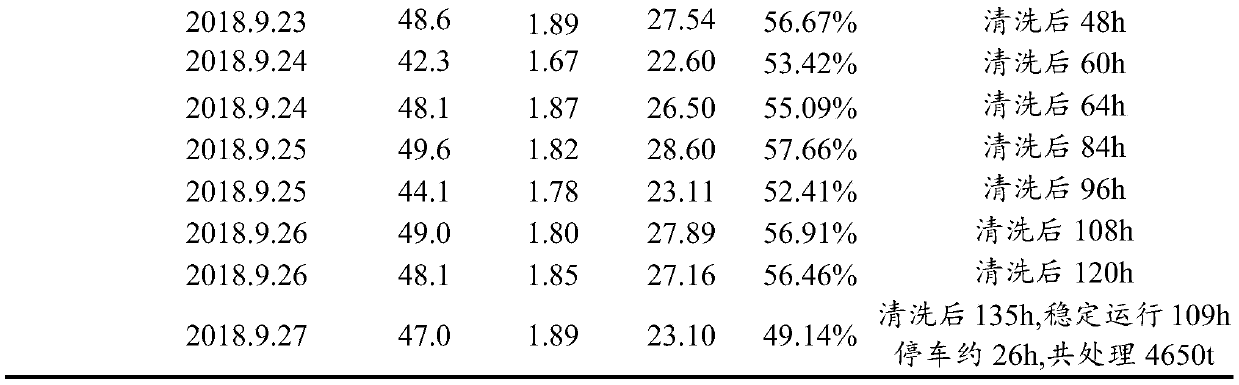

[0045] The reverse osmosis membrane equipment (3#RO membrane equipment) after fouling is cleaned with the reverse osmosis membrane alkaline cleaning agent in Example 1-3 respectively, wherein, the membrane of 3#RO membrane equipment (Xiamen Jiarong Technology Co., Ltd.) A total of 72 25×40 reverse osmosis membranes ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap