A kind of self-antibacterial water-based alkyd resin for color repair and preparation method thereof

A water-based alkyd resin, color-repairing technology, applied in coatings, polyester coatings, etc., can solve the problems of easy precipitation and unstable system, and achieve the effects of good adhesion, good wettability and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

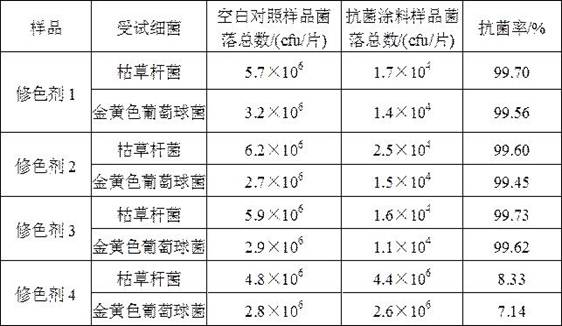

Examples

Embodiment 1

[0026] A self-antibacterial water-based alkyd resin for color correction, which consists of the following formula in parts by weight: 16.0 parts of refined castor oil, 8.0 parts of phthalic anhydride, 10.0 parts of maleic anhydride, 6.0 parts of hydroxyl Schiff base, trimethylol 13.0 parts of propane, 6.0 parts of neopentyl glycol hydroxypivalate, 0.8 parts of antioxidant, 2.5 parts of monobutyl itaconate, 3.5 parts of dimethylolpropionic acid, 12.0 parts of xylene, 7.5 parts of triethylamine , 100.0 parts of deionized water.

[0027] A kind of preparation method of self-antibacterial water-based alkyd resin for color correction in the present embodiment comprises the following steps:

[0028] a) In the multifunctional reaction kettle, add refined castor oil, phthalic anhydride, maleic anhydride, trimethylolpropane, neopentyl glycol hydroxypivalate, antioxidant, dimethylol in sequence according to the weight of the formula Propionic acid and xylene, N 2 , to remove the O in ...

Embodiment 2

[0032] A self-antibacterial water-based alkyd resin for color correction, which consists of the following formula in parts by weight: 17.0 parts of tung oil, 8.0 parts of acetic anhydride, 13.0 parts of phthalic anhydride, 5.0 parts of hydroxyl Schiff base, 4.0 parts of pentaerythritol, trimethylol 12.0 parts of propane, 6.8 parts of neopentyl glycol hydroxypivalate, 0.8 parts of antioxidant, 2.4 parts of monobutyl itaconate, 4.0 parts of dimethylolpropionic acid, 13.0 parts of xylene, and 6.8 parts of triethylamine , 115.0 parts of deionized water.

[0033] A kind of preparation method of self-antibacterial water-based alkyd resin for color correction in the present embodiment comprises the following steps:

[0034] a) In the multifunctional reactor, add tung oil, acetic anhydride, phthalic anhydride, pentaerythritol, trimethylolpropane, neopentyl glycol hydroxypivalate, antioxidant, dimethylol propionic acid and xylene, N 2 , to remove the O in the reactor 2 ;

[0035]b)...

Embodiment 3

[0038] A self-antibacterial water-based alkyd resin for color correction, which consists of the following formula in parts by weight: 18.0 parts of cottonseed oil, 18.0 parts of phthalic anhydride, 6.5 parts of hydroxyl Schiff base, 13.0 parts of trimethylolpropane, 1,2 , 5.0 parts of 4-butanetriol, 6.0 parts of neopentyl glycol hydroxypivalate, 0.7 parts of antioxidant, 2.2 parts of monobutyl itaconate, 3.8 parts of dimethylol propionic acid, 14.0 parts of xylene, 9.2 parts of triethylamine, 115.0 parts of deionized water.

[0039] A kind of preparation method of self-antibacterial water-based alkyd resin for color correction in the present embodiment comprises the following steps:

[0040] a) In the multifunctional reaction kettle, add cottonseed oil, phthalic anhydride, 1,2,4-butanetriol, trimethylolpropane, neopentyl glycol hydroxypivalate, antioxidant agent, dimethylolpropionic acid and xylene, pass through N 2 , to remove the O in the reactor 2 ;

[0041] b) Heat up ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com