Motor transmission connection mechanism for beam-pumping unit

A technology of transmission connection and motor, applied in the direction of engine components, engine seals, mechanical equipment, etc., can solve the problems affecting the service life of the motor, axial movement, etc., and achieve easy installation and disassembly, stable operation, and increased wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings of the description:

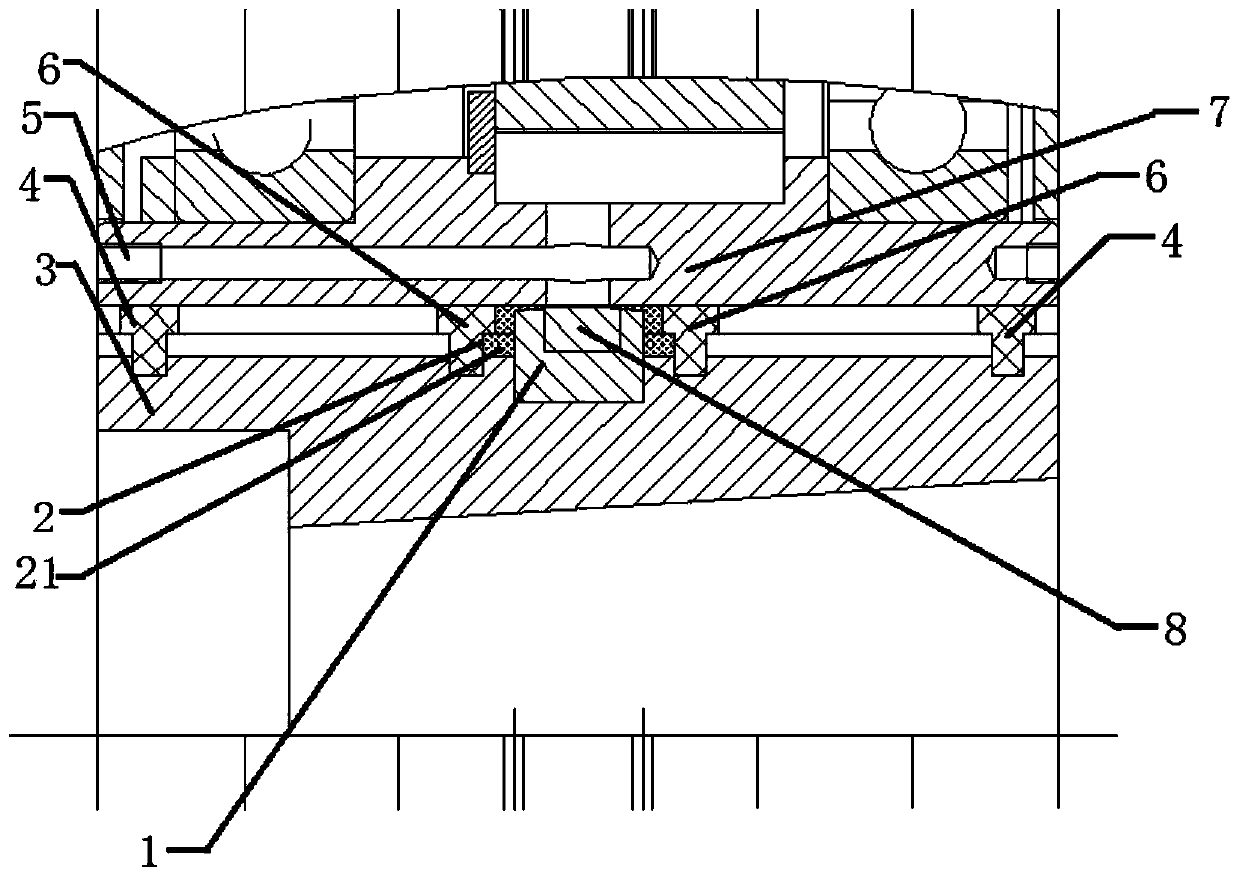

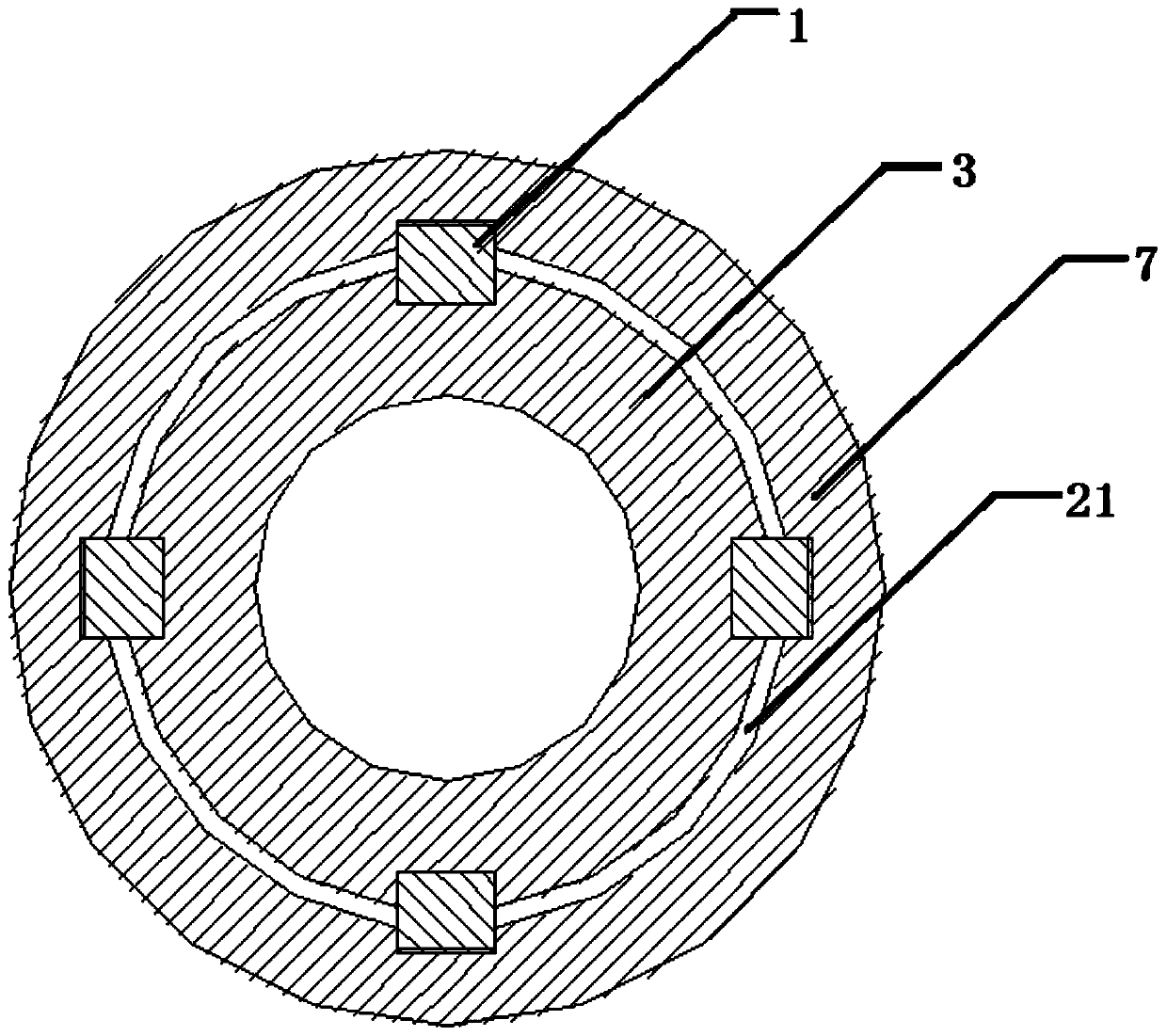

[0015] Such as figure 1 Shown, a kind of kowtow machine uses the position of motor transmission connection mechanism 88 in the motor, as figure 2 , image 3 As shown, a motor transmission connection mechanism for a kowtow machine, including a straight keyway 8, a motor shaft 7, four arc keys 1, a shaft sleeve 3, an inner sealing ring 6, an outer sealing ring 4, an oil seal 2, and an oil injection hole 5. The straight keyway 8 is fixedly connected with the motor shaft 7, the shaft sleeve 3 is installed on the inner side of the motor shaft 7, the four arc keys 1 are fixed on the shaft sleeve 3, and the four arc keys 1 Evenly distributed along the circumference of the shaft sleeve 3, the inner sealing ring 6 is set on the outside of the motor shaft 7, the outer sealing ring 4 is set on the outside of the inner sealing ring 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com