Discharging device with rice processing and weighing effects

A feeding device and rice processing technology, applied to measuring devices, automatic feeding/discharging weighing equipment, weighing, etc., can solve the problems of not being able to meet production needs, poor uniformity of manual feeding, and low operating efficiency , to achieve good self-locking, easy to stop, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

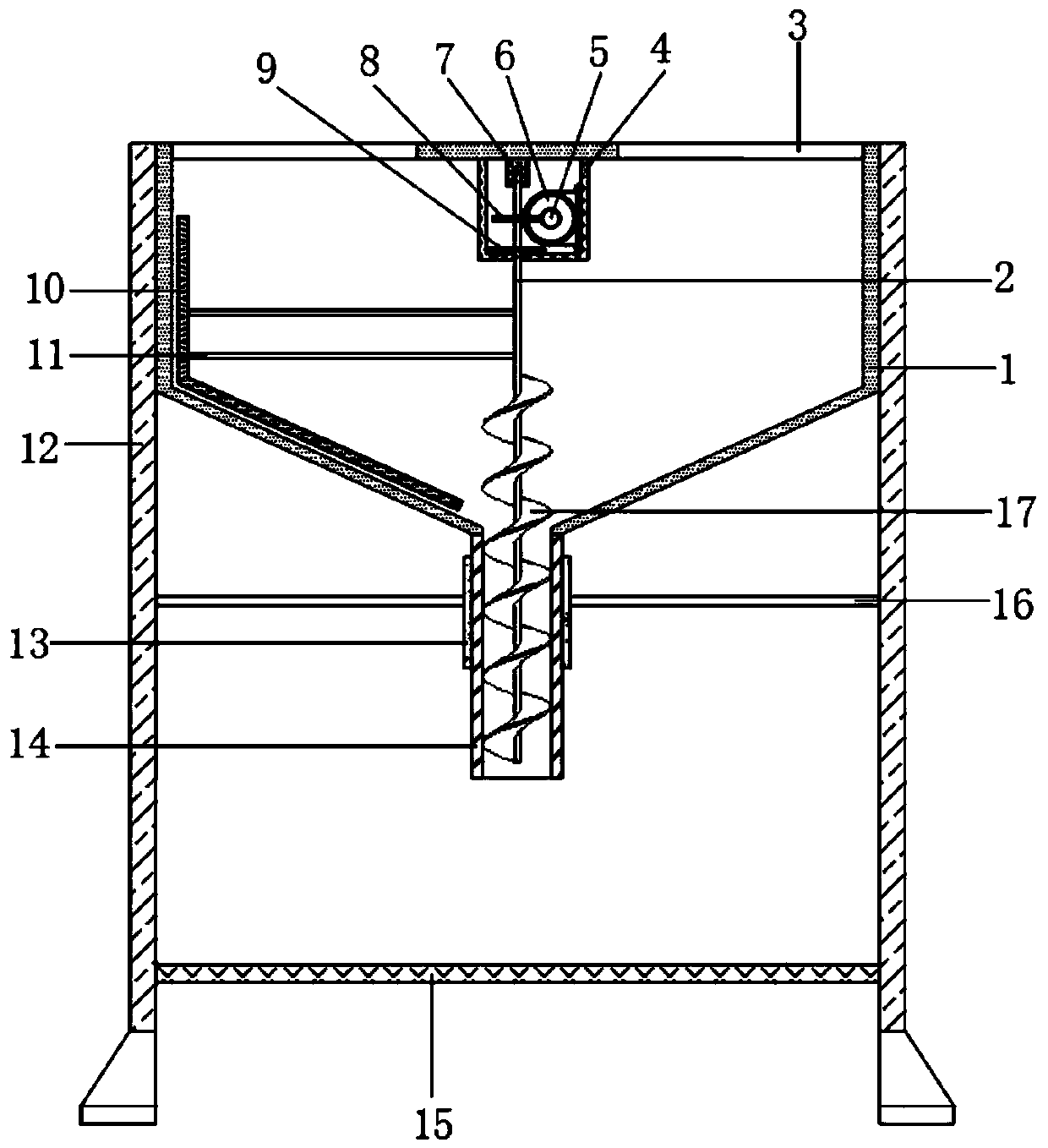

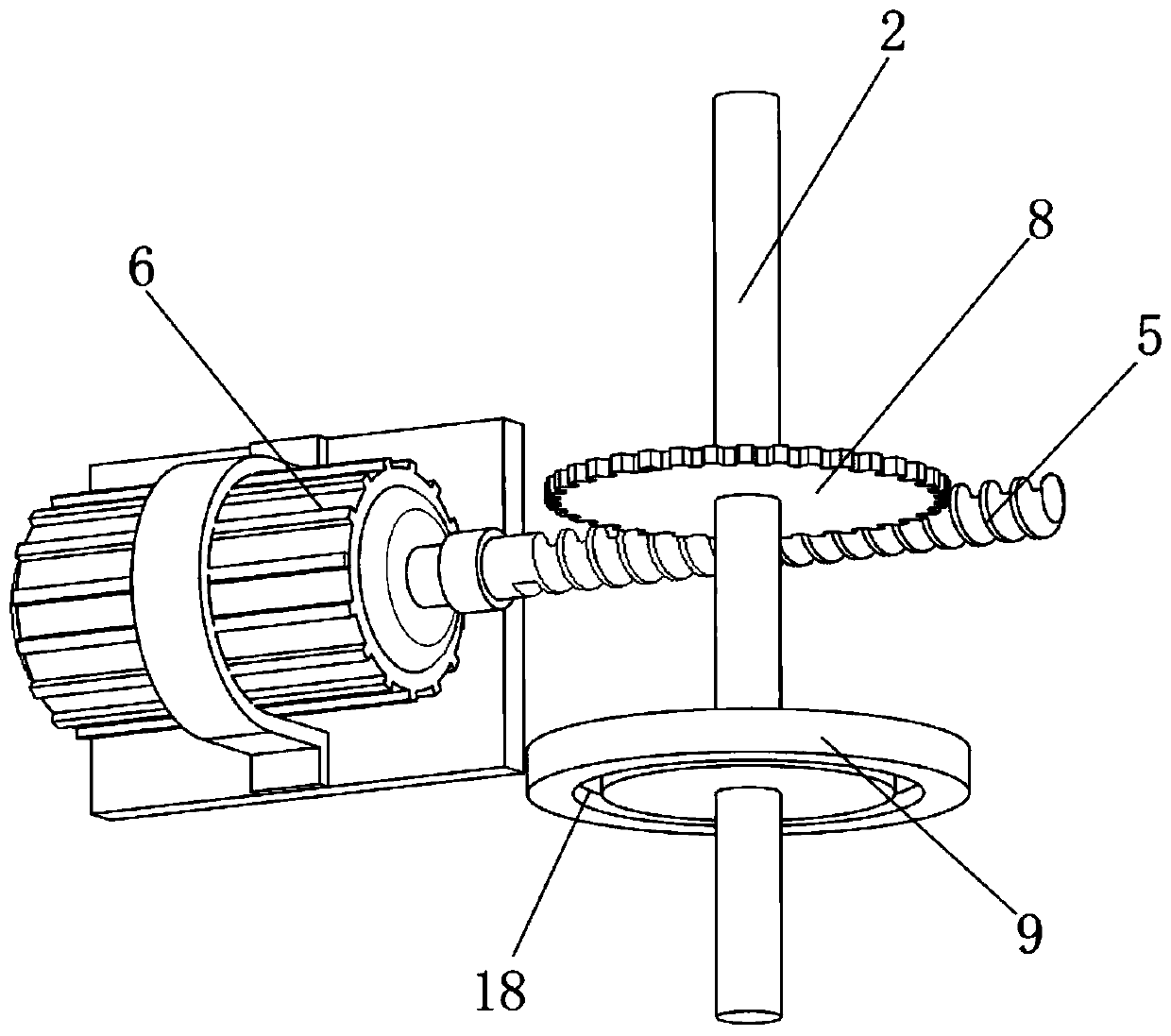

[0027] refer to Figure 1-2 , a kind of discharge device for rice processing and weighing, comprising a storage box 1 with brackets 12 welded at the four corners of the outer wall of the circumference, an active discharge mechanism is installed inside the storage box 1, and the active discharge mechanism includes a bolt fixed on the top of the storage box 1 The bearing seat 7 of the inner wall, the bearing seat 7 is rotatably connected with the rotating rod 2, and the bottom end of the storage box 1 is welded with the lower material cylinder end 14, and the bottom end of the rotating rod 2 is welded with a twisting rod that is compatible with the lower material cylinder end 14. The dragon bar 17, the top of the storage box 1 close to the side of the rotating rod 2 is fixed with the installation box 4 by bolts, and the inner wall of one side of the installation box 4 is fixed with the geared motor 6 by bolts, and the output shaft of the geared motor 6 is passed through the coupl...

Embodiment 2

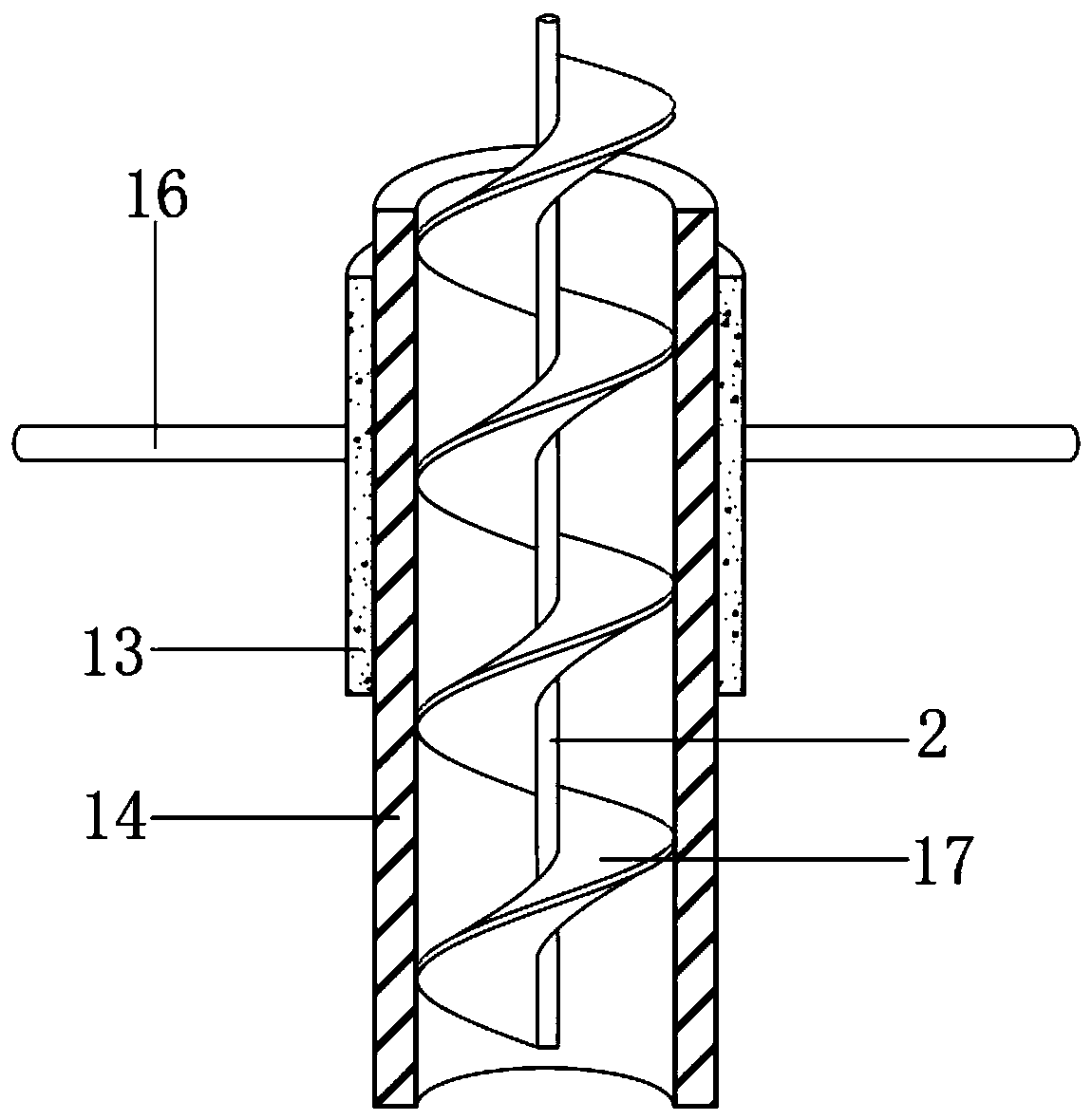

[0034] refer to figure 1 and image 3 , a kind of discharging device for rice processing and weighing. In order to further improve the stability of the device, this embodiment also includes a reinforcement mechanism installed on the opposite side of the bracket 12 and the lower barrel end 14 compared to Embodiment 1, and the reinforcement The mechanism comprises a reinforcing cylinder 13 welded to the outer peripheral wall of the lower cylinder end 14 .

[0035] Wherein, a reinforcing rod 16 is welded on opposite sides of the reinforcing tube 13 and the bracket 12 .

[0036] Working principle: when in use, the stability of the discharging device can be effectively improved by utilizing the mutual cooperation between the reinforcing rod 16 and the reinforcing cylinder 13 to utilize their supporting effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com