A power semiconductor module packaging structure

A power semiconductor and module packaging technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problem of power semiconductor module current sharing, heat dissipation, thermal stress, and reliability affecting the reliable use of power semiconductor modules, Reducing the reliability of power semiconductor modules The uniformity of power semiconductor modules and the inability to directly manufacture single-chip chips can achieve the effects of reducing costs, reducing the number of chips, and the number of pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

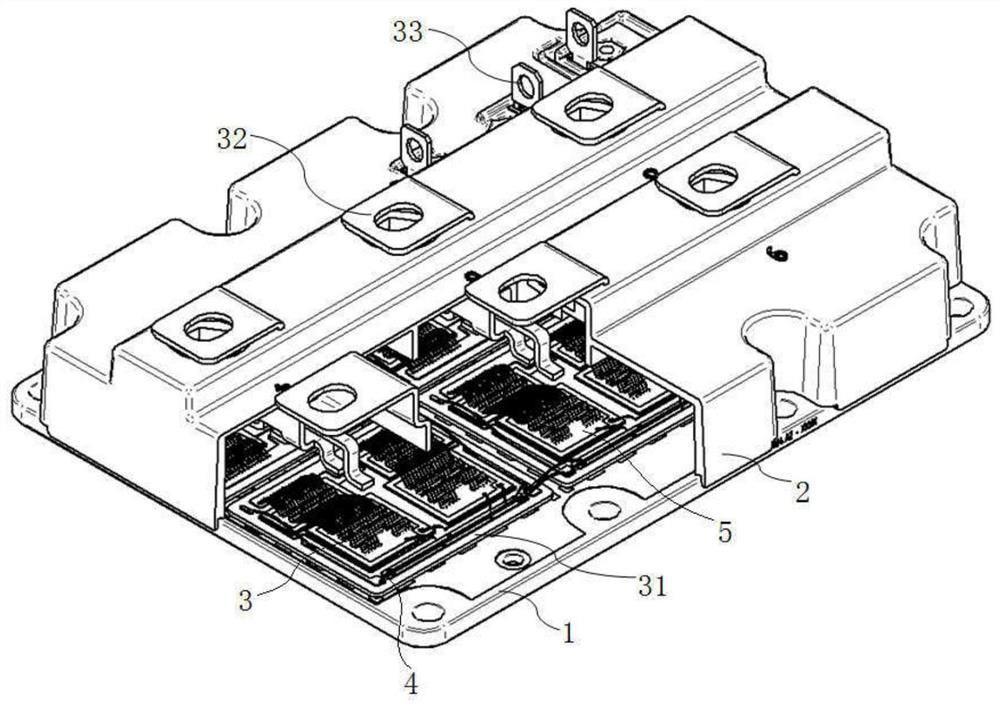

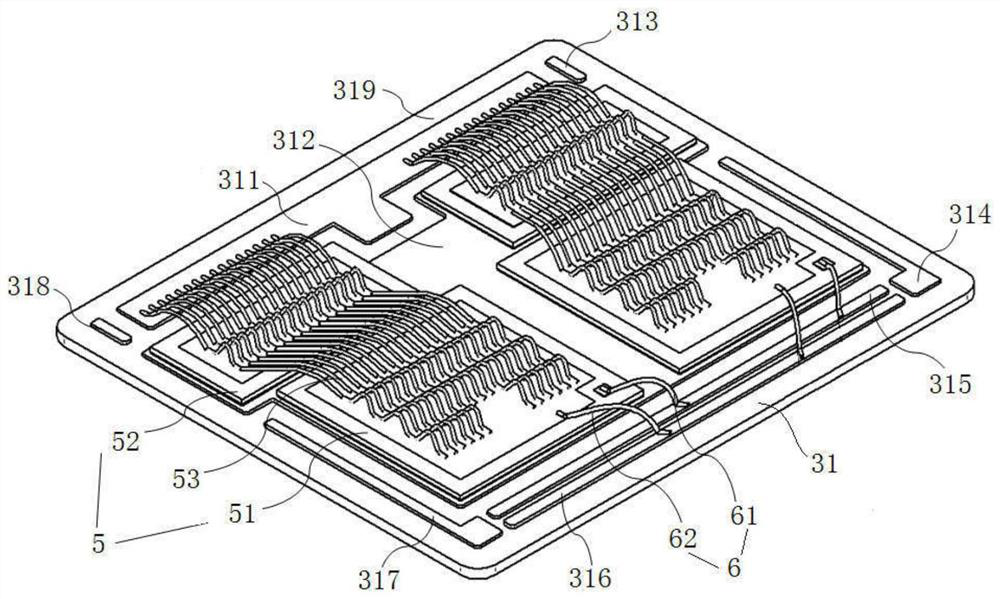

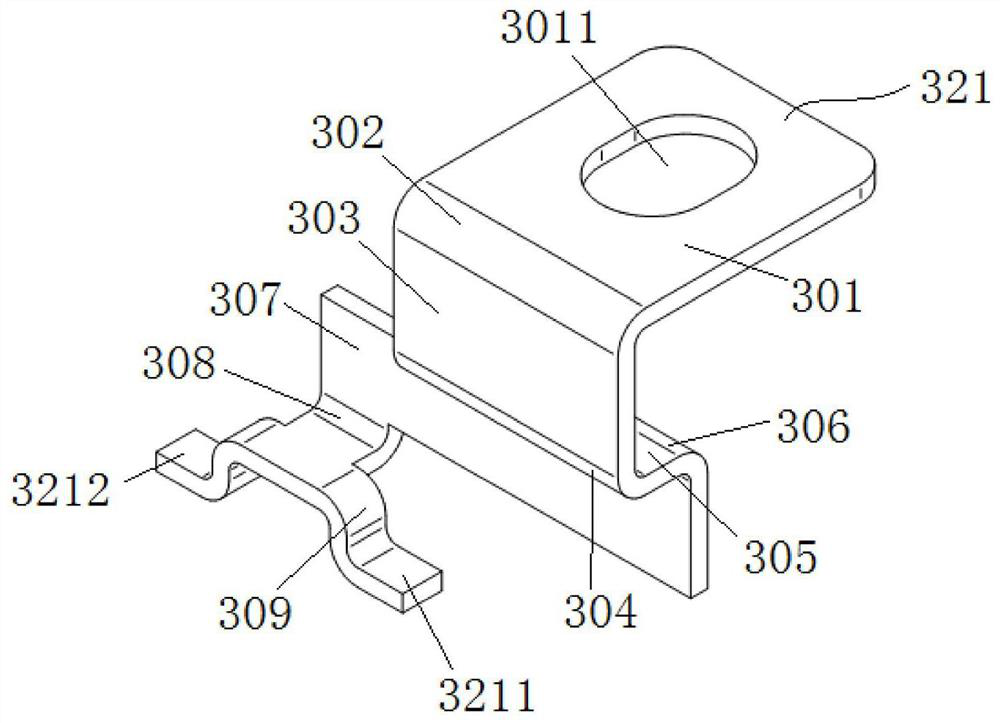

[0031] like figure 1 As shown, the power semiconductor module packaging structure proposed by the present invention includes a substrate 1; a housing 2, which is sealed and fastened to the substrate 1; In the accommodation space, it is used to form a topology control circuit structure. The power semiconductor module subunit 3 includes a plurality of backing plates 31 arranged at intervals on the substrate 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com