High-voltage ultrasonic wave generating circuit and high-voltage ultrasonic wave transmitting and receiving circuit

A high-voltage circuit and generation circuit technology, which is used in the generation of ultrasonic/sonic/infrasonic waves, material analysis using sonic emission technology, instruments, etc. It can solve problems such as the flow measurement of complex media and large-diameter pipelines that cannot be well solved. , to achieve the effect of limiting the voltage too high and protecting it from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

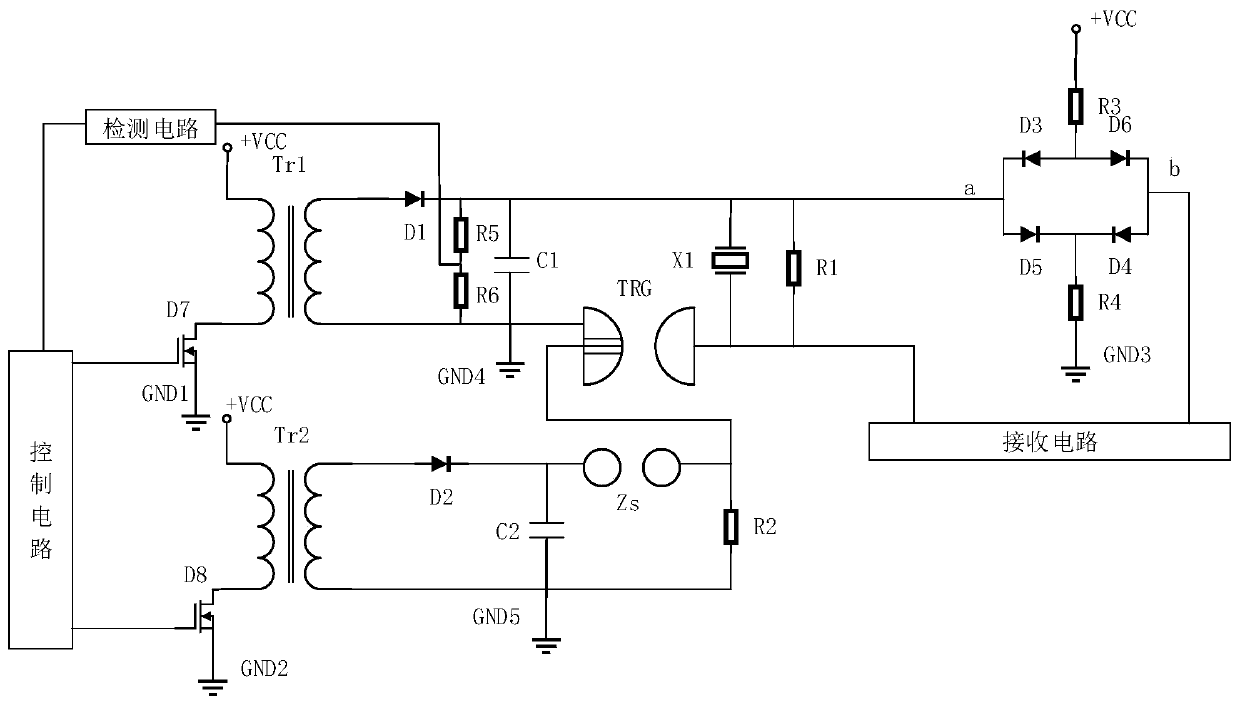

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

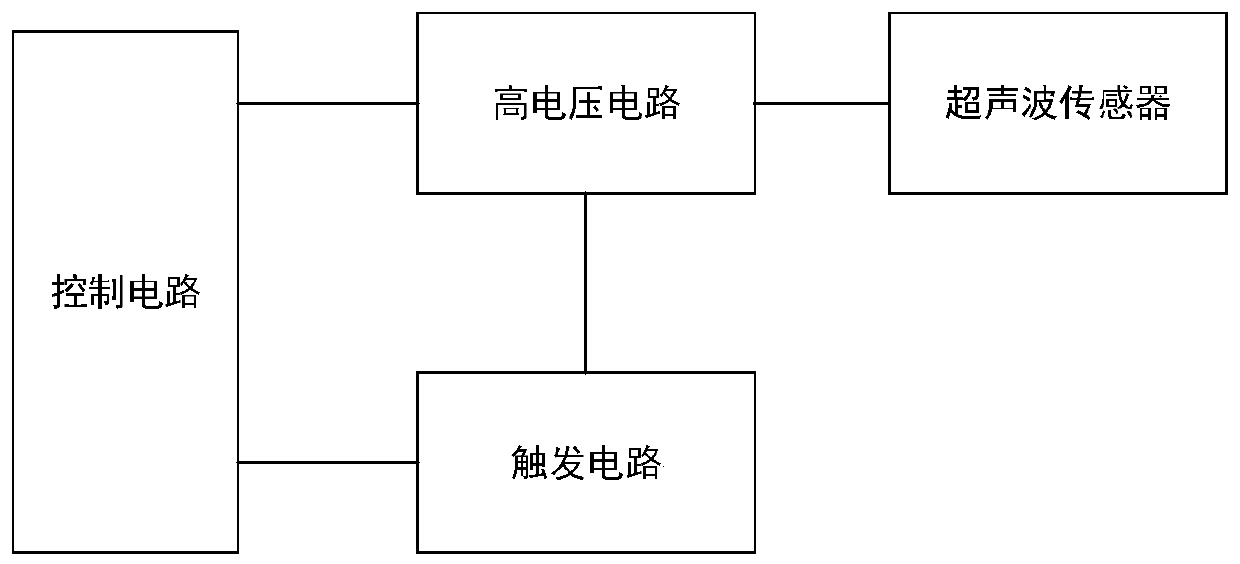

[0041] figure 1 It is a block diagram of the high-voltage ultrasonic generating circuit of the present invention, as figure 1 As shown, the present invention constructs a high-voltage ultrasonic generating circuit, including: a trigger circuit, a high-voltage circuit, and an ultrasonic sensor X1 connected in sequence, and a control circuit that provides start pulses for the trigger circuit and the high-voltage circuit respectively.

[0042] Wherein, the control circuit can control the trigger circuit to be in an unloaded state, control the high voltage circuit to boost to a preset high voltage, and keep the high voltage circuit disconnected from the ultrasonic sensor X1.

[0043] The control circuit can control the tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com