Multi-station floating clamper for clamping sheet workpieces

A multi-station and gripper technology, used in metal processing mechanical parts, clamping, positioning devices, etc., can solve problems such as unfavorable clamping, low efficiency, affecting production efficiency, etc., to improve clamping efficiency and eliminate size The effect of the difference on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

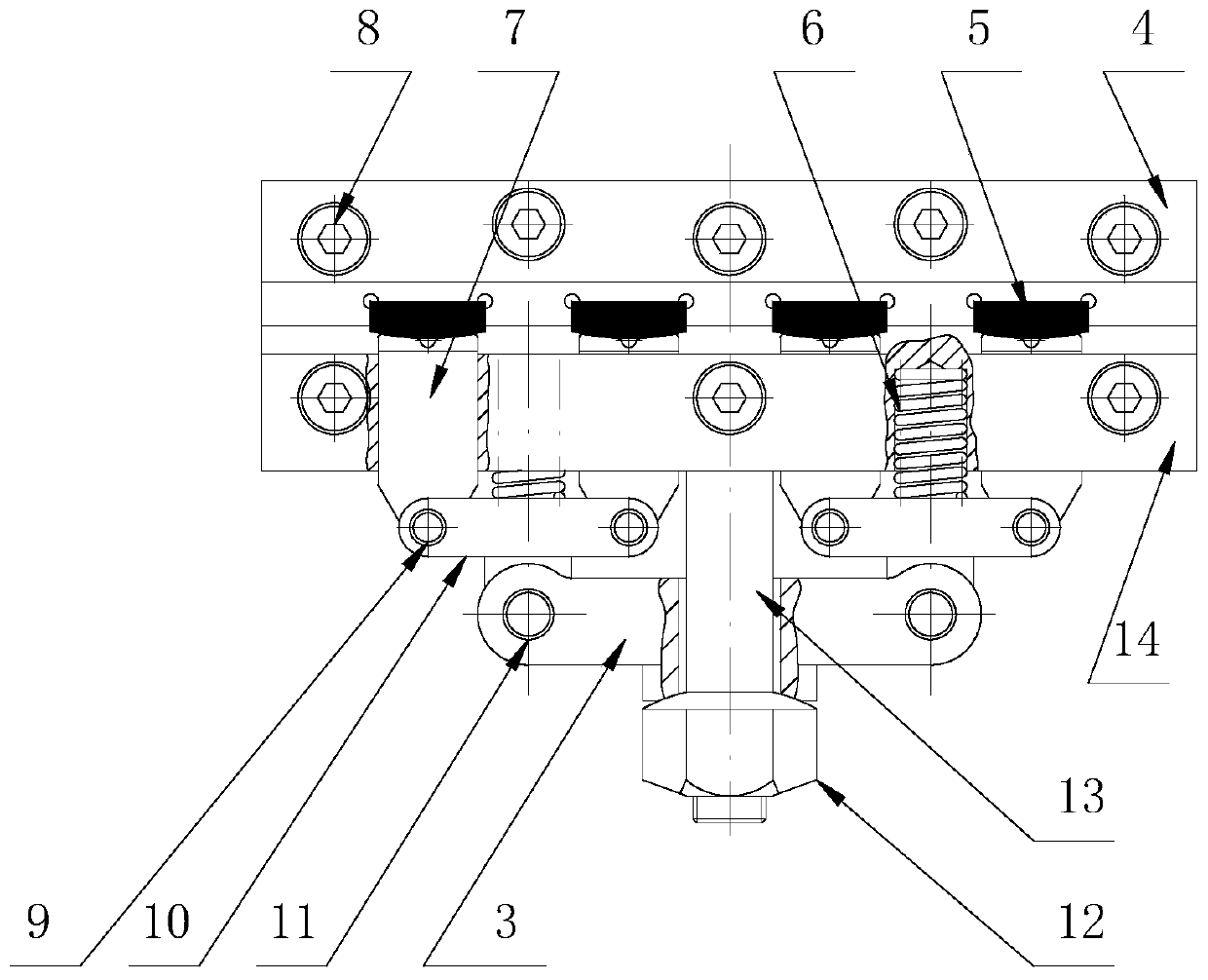

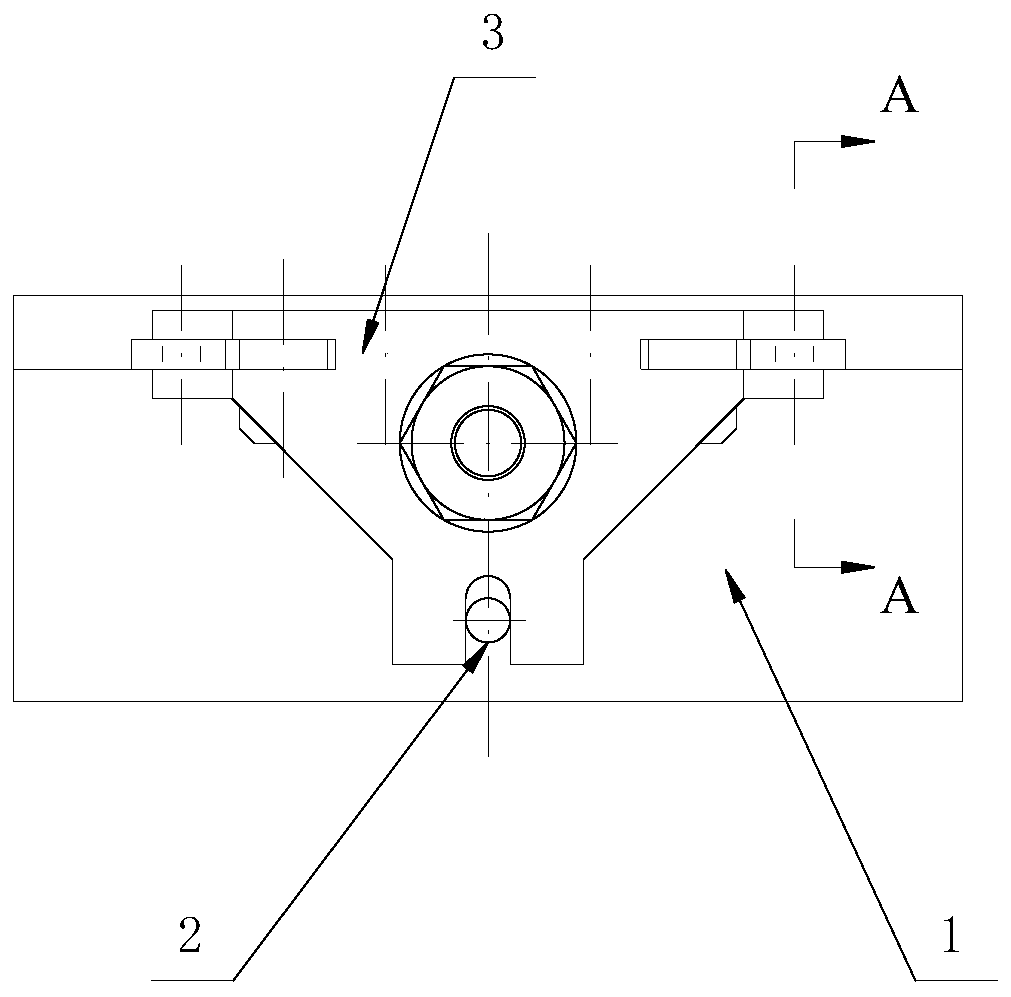

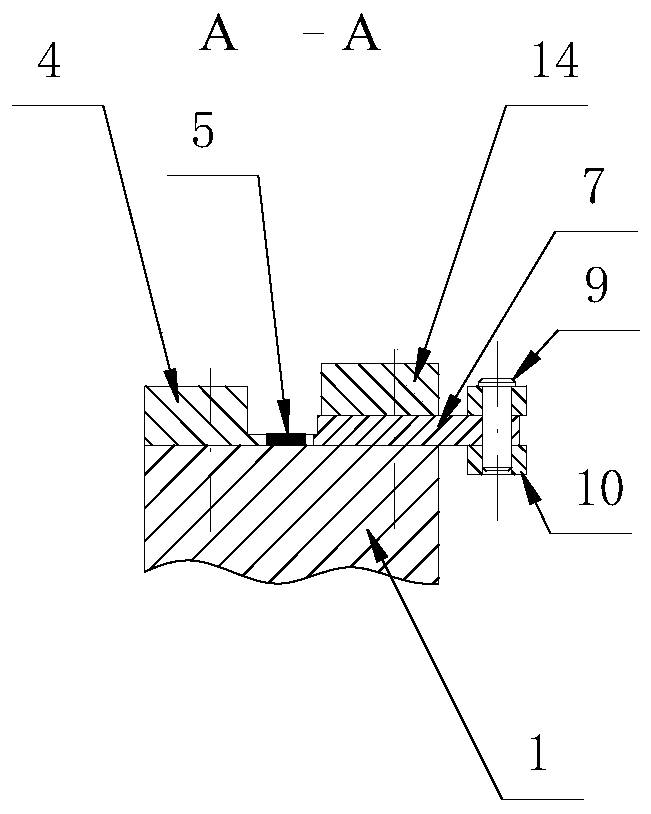

[0018] refer to Figure 1-Figure 2 . In the preferred embodiment described below, a multi-station floating clamper for clamping thin workpieces includes: a base 1 fixed on a workbench during processing, a press plate 3 for clamping thin workpieces 5, and all structures The parts are distributed and installed on the base 1, wherein the base 1 is used as the basic part fixed on the workbench during processing; the positioning plate 4 is processed according to the shape of the sheet workpiece 5, and its surface is additionally processed with counterbores for connection; linkage The push plate 7 and the limit plate 14 have a sliding fit relationship; the pressure plate 3 arranged on the base workbench is symmetrical to the center line of the workbench, and a positioning plate 4 is arranged behind the pressure plate 3, and a plurality of sheet workpieces 5 are arranged in a linear array on the base to work. On the stage, it is positioned by the gap on the positioning plate 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com