A special cleaning equipment for printing presses

A technology for cleaning equipment and printing machines, applied in printing machines, general parts of printing machinery, printing and other directions, can solve problems such as the influence of the service life of the nozzle, limited cleaning effect, equipment damage, etc., to achieve good equipment, novel structure, and extended use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

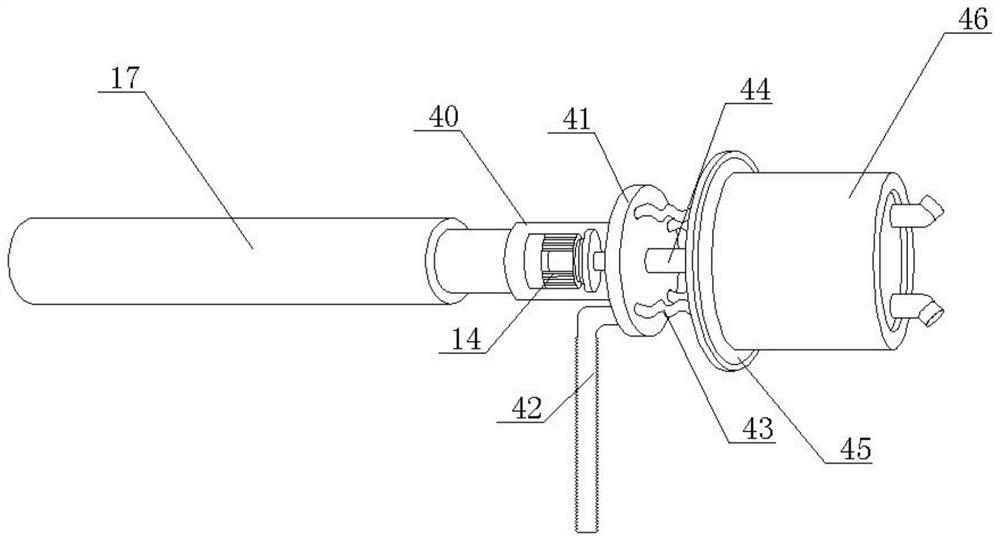

[0027] As a preferred embodiment of the present invention, the control board 5 passes through the command circuit and the water pump one 47 of the command device 9, the water pump two 48, the valve one 11, the valve two 12, the motor one 13, the motor two 14, the electric lifting column 15. Cylinder one 16 and cylinder two 17 are electrically connected.

[0028] As a preferred embodiment of the present invention, the control board 5 is respectively connected to the distance sensor 1 , the light sensor 2 , the first cylinder switch 3 and the second cylinder switch 10 of the monitoring device 4 through wires.

[0029] As a preferred embodiment of the present invention, the control board 5 includes an intelligent processor 6 and a control switch 7, and the intelligent processor 6 includes a printed circuit main board and a microprocessor and a processing unit arranged on the printed circuit main board. chip, the microprocessor is electrically connected to the processing chip.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com