Computational method of high-gas-liquid-ratio horizontal well critical liquid-carrying flow

A liquid-carrying flow rate and calculation method technology, which is applied in the calculation field of critical liquid-carrying flow rate of high gas-liquid ratio horizontal wells, can solve the problem of affecting normal gas production of high gas-liquid ratio horizontal wells, and the calculation model is difficult to apply to high gas-liquid ratio horizontal wells problems such as the critical liquid-carrying flow rate and the inability to accurately obtain the critical liquid-carrying flow rate of horizontal wells with high gas-liquid ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

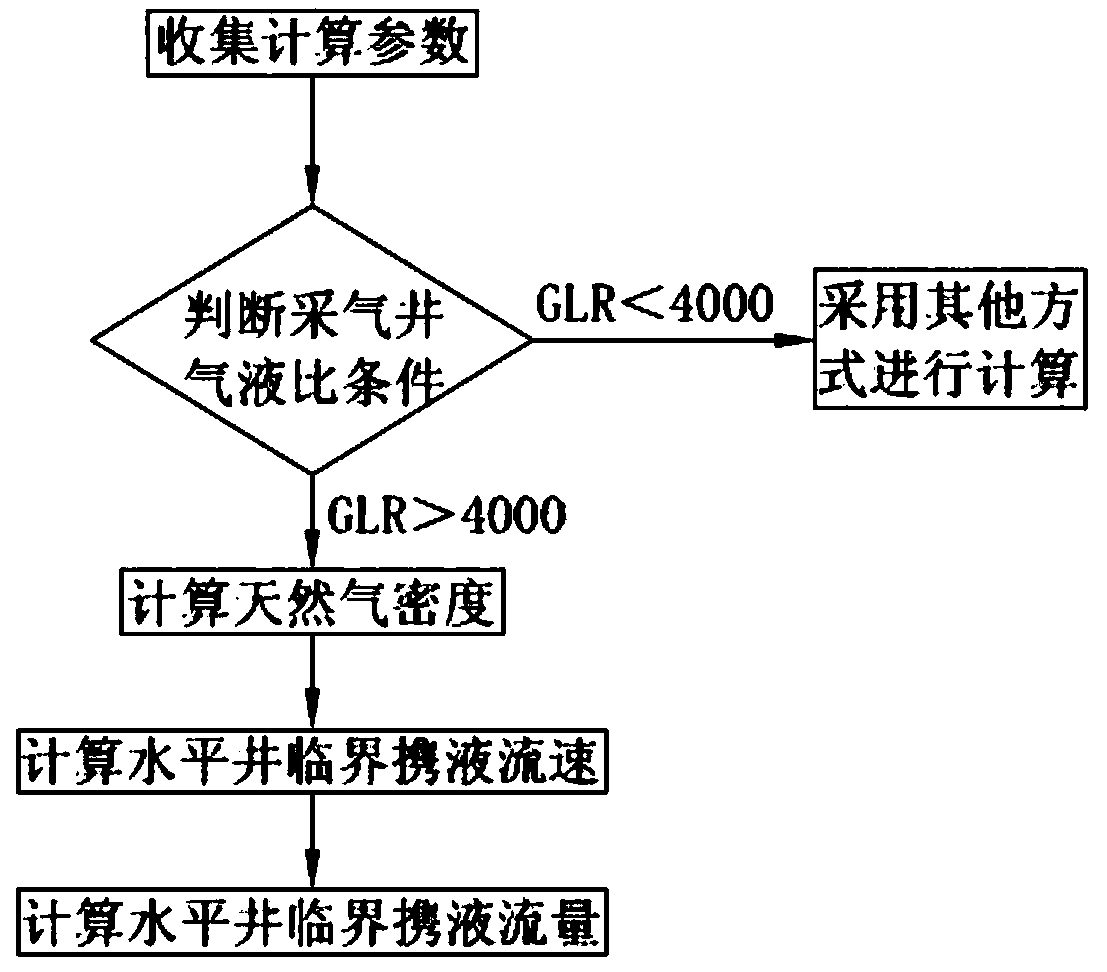

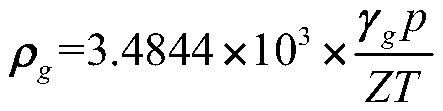

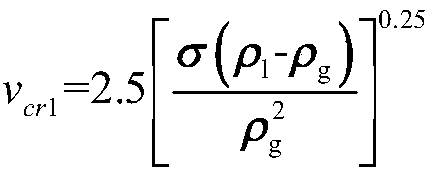

[0057] Such as figure 1 As shown, a calculation method for the critical liquid-carrying flow rate of a high gas-liquid ratio horizontal well, by calculating the critical liquid-carrying flow rate v of the vertical well section cr1 , critical liquid-carrying velocity v in the inclined well section cr2 and the critical liquid-carrying velocity v in the horizontal well section cr3 , choose the maximum among the three as the critical liquid-carrying velocity v of the horizontal well cr , using the calculation formula of flow velocity and flow rate to calculate the critical liquid-carrying flow rate of the horizontal well, which specifically includes the following steps: Step 1: Collect calculation parameters: the calculation parameters include production parameters and pipe string parameters, and the production parameters include wellhead pressure, temperature , gas-liquid ratio, and physical parameters of the fluid in the well. The parameters of the pipe string include the aver...

Embodiment 2

[0097] A calculation method of the critical liquid-carrying flow rate of a high gas-liquid ratio horizontal well in this embodiment, taking the actual parameters of a certain horizontal well X as an example, the calculation method of this embodiment is described, wherein, the structural parameters and production data of X well The table is as follows:

[0098] Well X structural parameters and production data table

[0099]

[0100]

[0101] According to the calculation method of the critical liquid-carrying flow rate of a high gas-liquid ratio horizontal well in this embodiment, the calculation of the critical liquid-carrying flow rate of Well X specifically includes the following steps in sequence: Step 2: Judging the gas-liquid ratio condition of the gas production well: due to the The gas-liquid ratio parameter of well X is 26710, which is greater than 4000, which meets the condition of high gas-liquid ratio; Step 3: Calculate the natural gas density ρ g : According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com